Popular Woodworking 2006-06 № 155, страница 51

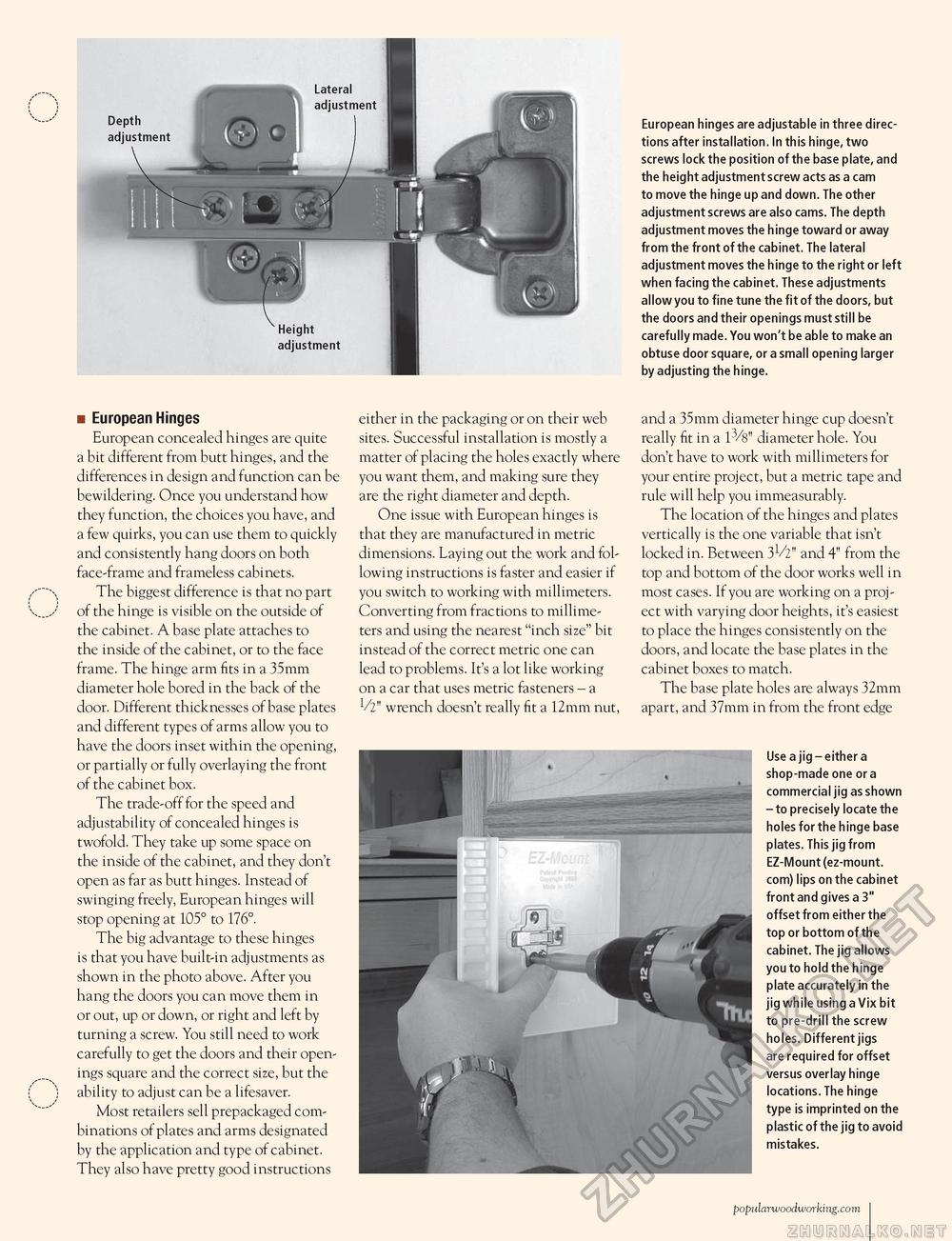

■ European Hinges European concealed hinges are quite a bit different from butt hinges, and the differences in design and function can be bewildering. Once you understand how they function, the choices you have, and a few quirks, you can use them to quickly and consistently hang doors on both face-frame and frameless cabinets. The biggest difference is that no part of the hinge is visible on the outside of the cabinet. A base plate attaches to the inside of the cabinet, or to the face frame. The hinge arm fits in a 35mm diameter hole bored in the back of the door. Different thicknesses of base plates and different types of arms allow you to have the doors inset within the opening, or partially or fully overlaying the front of the cabinet box. The trade-off for the speed and adjustability of concealed hinges is twofold. They take up some space on the inside of the cabinet, and they don't open as far as butt hinges. Instead of swinging freely, European hinges will stop opening at 105° to 176°. The big advantage to these hinges is that you have built-in adjustments as shown in the photo above. After you hang the doors you can move them in or out, up or down, or right and left by turning a screw. You still need to work carefully to get the doors and their openings square and the correct size, but the ability to adjust can be a lifesaver. Most retailers sell prepackaged combinations of plates and arms designated by the application and type of cabinet. They also have pretty good instructions either in the packaging or on their web sites. Successful installation is mostly a matter of placing the holes exactly where you want them, and making sure they are the right diameter and depth. One issue with European hinges is that they are manufactured in metric dimensions. Laying out the work and following instructions is faster and easier if you switch to working with millimeters. Converting from fractions to millimeters and using the nearest "inch size" bit instead of the correct metric one can lead to problems. It's a lot like working on a car that uses metric fasteners - a 1/2" wrench doesn't really fit a 12mm nut, European hinges are adjustable in three directions after installation. In this hinge, two screws lock the position of the base plate, and the height adjustment screw acts as a cam to move the hinge up and down. The other adjustment screws are also cams. The depth adjustment moves the hinge toward or away from the front of the cabinet. The lateral adjustment moves the hinge to the right or left when facing the cabinet. These adjustments allow you to fine tune the fit of the doors, but the doors and their openings must still be carefully made. You won't be able to make an obtuse door square, or a small opening larger by adjusting the hinge. and a 35mm diameter hinge cup doesn't really fit in a 13/8" diameter hole. You don't have to work with millimeters for your entire project, but a metric tape and rule will help you immeasurably. The location of the hinges and plates vertically is the one variable that isn't locked in. Between 31/2" and 4" from the top and bottom of the door works well in most cases. If you are working on a project with varying door heights, it's easiest to place the hinges consistently on the doors, and locate the base plates in the cabinet boxes to match. The base plate holes are always 32mm apart, and 37mm in from the front edge Use a jig - either a shop-made one or a commercial jig as shown - to precisely locate the holes for the hinge base plates. This jig from EZ-Mount (ez-mount. com) lips on the cabinet front and gives a 3" offset from either the top or bottom of the cabinet. The jig allows you to hold the hinge plate accurately in the jig while using a Vix bit to pre-drill the screw holes. Different jigs are required for offset versus overlay hinge locations. The hinge type is imprinted on the plastic of the jig to avoid mistakes. popularwoodworking.com I 51 |