Popular Woodworking 2006-06 № 155, страница 53

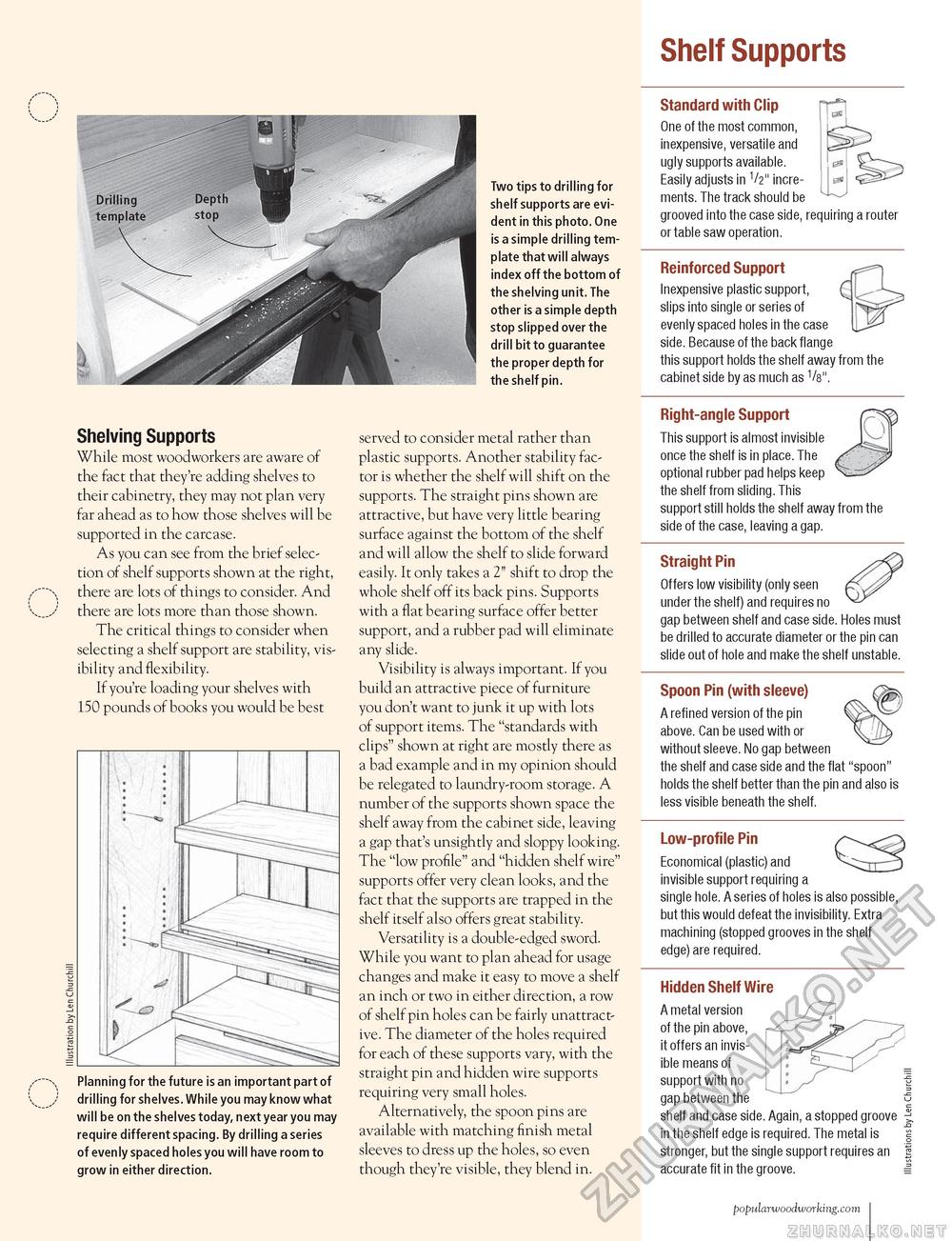

Shelf Supports Shelving Supports While most woodworkers are aware of the fact that they're adding shelves to their cabinetry, they may not plan very far ahead as to how those shelves will be supported in the carcase. As you can see from the brief selection of shelf supports shown at the right, there are lots of things to consider. And there are lots more than those shown. The critical things to consider when selecting a shelf support are stability, visibility and flexibility. If you're loading your shelves with 150 pounds of books you would be best Planning for the future is an important part of drilling for shelves. While you may know what will be on the shelves today, next year you may require different spacing. By drilling a series of evenly spaced holes you will have room to grow in either direction. Two tips to drilling for shelf supports are evident in this photo. One is a simple drilling template that will always index off the bottom of the shelving unit. The other is a simple depth stop slipped over the drill bit to guarantee the proper depth for the shelf pin. served to consider metal rather than plastic supports. Another stability factor is whether the shelf will shift on the supports. The straight pins shown are attractive, but have very little bearing surface against the bottom of the shelf and will allow the shelf to slide forward easily. It only takes a 2" shift to drop the whole shelf off its back pins. Supports with a flat bearing surface offer better support, and a rubber pad will eliminate any slide. Visibility is always important. If you build an attractive piece of furniture you don't want to junk it up with lots of support items. The "standards with clips" shown at right are mostly there as a bad example and in my opinion should be relegated to laundry-room storage. A number of the supports shown space the shelf away from the cabinet side, leaving a gap that's unsightly and sloppy looking. The "low profile" and "hidden shelf wire" supports offer very clean looks, and the fact that the supports are trapped in the shelf itself also offers great stability. Versatility is a double-edged sword. While you want to plan ahead for usage changes and make it easy to move a shelf an inch or two in either direction, a row of shelf pin holes can be fairly unattractive. The diameter of the holes required for each of these supports vary, with the straight pin and hidden wire supports requiring very small holes. Alternatively, the spoon pins are available with matching finish metal sleeves to dress up the holes, so even though they're visible, they blend in. Standard with Clip One of the most common, inexpensive, versatile and ugly supports available. Easily adjusts in V2" increments. The track should be grooved into the case side, requiring a router or table saw operation. Reinforced Support Inexpensive plastic support, slips into single or series of evenly spaced holes in the case side. Because of the back flange this support holds the shelf away from the cabinet side by as much as 1/8". Right-angle Support This support is almost invisible once the shelf is in place. The optional rubber pad helps keep the shelf from sliding. This support still holds the shelf away from the side of the case, leaving a gap. Straight Pin Offers low visibility (only seen underthe shelf) and requires no gap between shelf and case side. Holes must be drilled to accurate diameter or the pin can slide out of hole and make the shelf unstable. Spoon Pin (with sleeve) A refined version of the pin above. Can be used with or without sleeve. No gap between the shelf and case side and the flat "spoon" holds the shelf better than the pin and also is less visible beneath the shelf. Low-profile Pin Economical (plastic) and invisible support requiring a single hole. A series of holes is also possible, but this would defeat the invisibility. Extra machining (stopped grooves in the shelf edge) are required. Hidden Shelf Wire A metal version of the pin above, it offers an invisible means of support with no gap between the shelf and case side. Again, a stopped groove in the shelf edge is required. The metal is stronger, but the single support requires an accurate fit in the groove. popularwoodworking.com I 53 |