Popular Woodworking 2006-06 № 155, страница 52

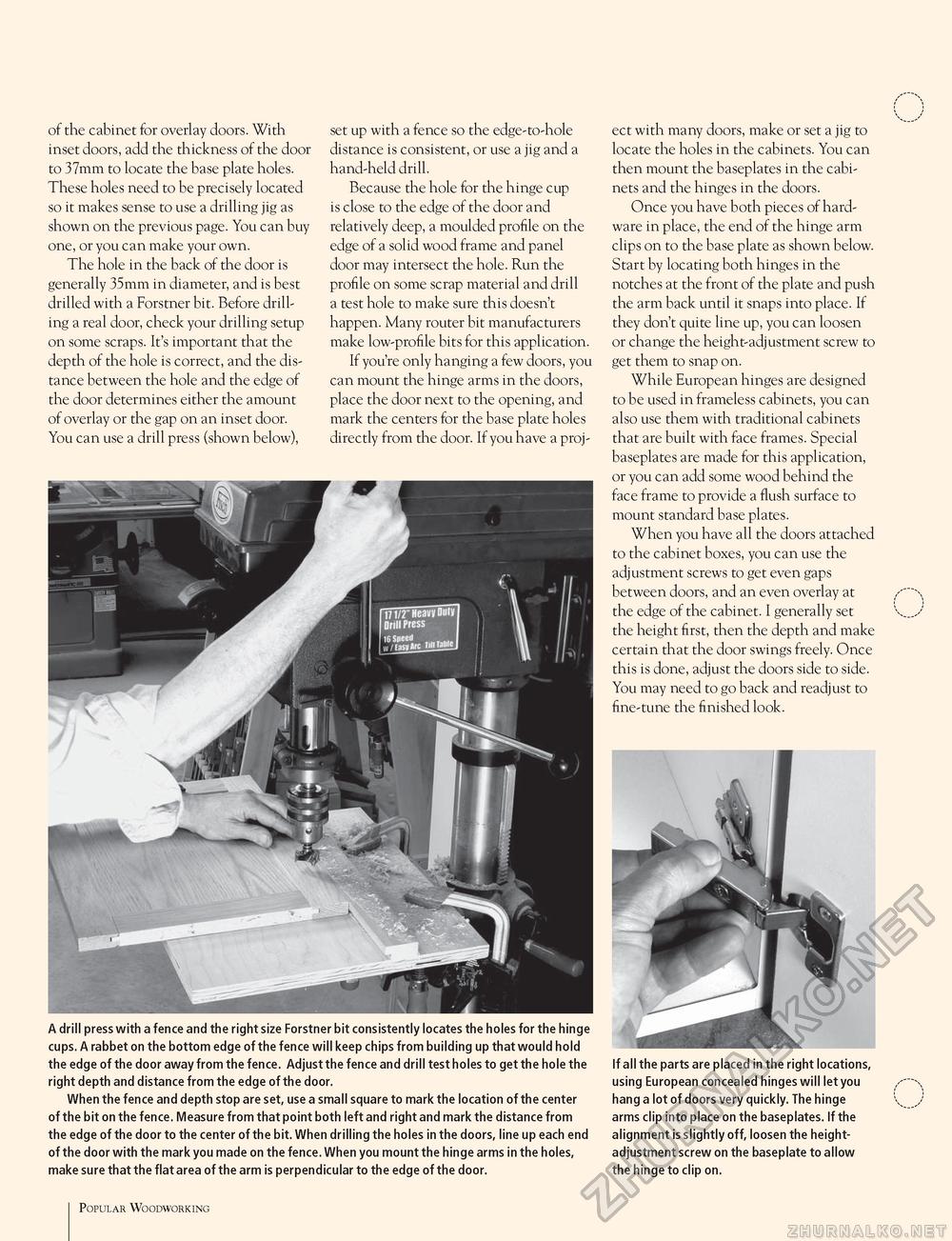

of the cabinet for overlay doors. With inset doors, add the thickness of the door to 37mm to locate the base plate holes. These holes need to be precisely located so it makes sense to use a drilling jig as shown on the previous page. You can buy one, or you can make your own. The hole in the back of the door is generally 35mm in diameter, and is best drilled with a Forstner bit. Before drilling a real door, check your drilling setup on some scraps. It's important that the depth of the hole is correct, and the distance between the hole and the edge of the door determines either the amount of overlay or the gap on an inset door. You can use a drill press (shown below), set up with a fence so the edge-to-hole distance is consistent, or use a jig and a hand-held drill. Because the hole for the hinge cup is close to the edge of the door and relatively deep, a moulded profile on the edge of a solid wood frame and panel door may intersect the hole. Run the profile on some scrap material and drill a test hole to make sure this doesn't happen. Many router bit manufacturers make low-profile bits for this application. If you're only hanging a few doors, you can mount the hinge arms in the doors, place the door next to the opening, and mark the centers for the base plate holes directly from the door. If you have a proj- ect with many doors, make or set a jig to locate the holes in the cabinets. You can then mount the baseplates in the cabinets and the hinges in the doors. Once you have both pieces of hardware in place, the end of the hinge arm clips on to the base plate as shown below. Start by locating both hinges in the notches at the front of the plate and push the arm back until it snaps into place. If they don't quite line up, you can loosen or change the height-adjustment screw to get them to snap on. While European hinges are designed to be used in frameless cabinets, you can also use them with traditional cabinets that are built with face frames. Special baseplates are made for this application, or you can add some wood behind the face frame to provide a flush surface to mount standard base plates. When you have all the doors attached to the cabinet boxes, you can use the adjustment screws to get even gaps between doors, and an even overlay at the edge of the cabinet. I generally set the height first, then the depth and make certain that the door swings freely. Once this is done, adjust the doors side to side. You may need to go back and readjust to fine-tune the finished look. If all the parts are placed in the right locations, using European concealed hinges will let you hang a lot of doors very quickly. The hinge arms clip into place on the baseplates. If the alignment is slightly off, loosen the height-adjustment screw on the baseplate to allow the hinge to clip on. A drill press with a fence and the right size Forstner bit consistently locates the holes for the hinge cups. A rabbet on the bottom edge of the fence will keep chips from building up that would hold the edge of the door away from the fence. Adjust the fence and drill test holes to get the hole the right depth and distance from the edge of the door. When the fence and depth stop are set, use a small square to mark the location of the center of the bit on the fence. Measure from that point both left and right and mark the distance from the edge of the door to the center of the bit. When drilling the holes in the doors, line up each end of the door with the mark you made on the fence. When you mount the hinge arms in the holes, make sure that the flat area of the arm is perpendicular to the edge of the door. Popular Woodworking |