Popular Woodworking 2006-06 № 155, страница 78

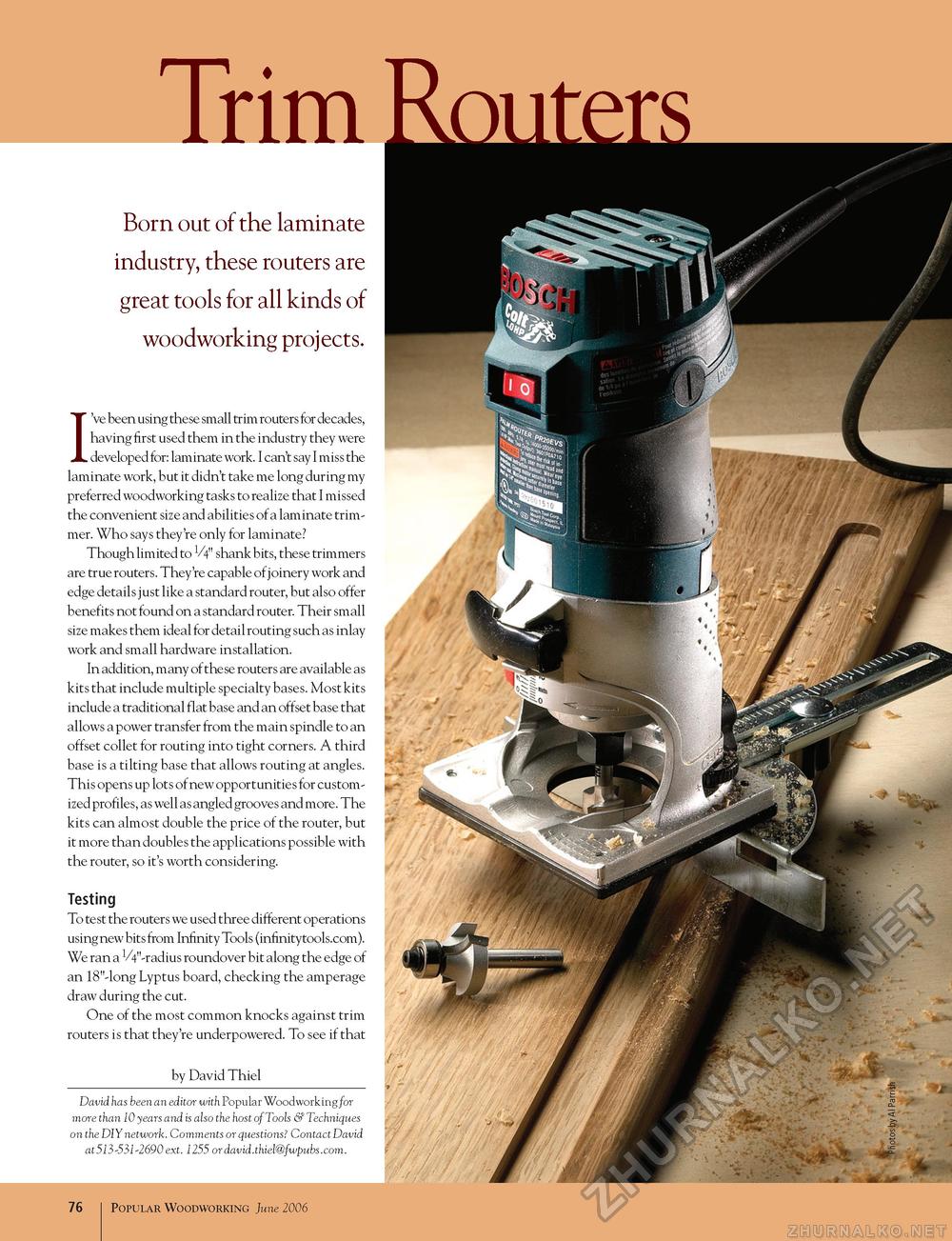

TrimBorn out of the laminate industry, these routers are great tools for all kinds of woodworking projects. I've been using these small trim routers for decades, having first used them in the industry they were developed for: laminate work. I can't say I miss the laminate work, but it didn't take me long during my preferred woodworking tasks to realize that I missed the convenient size and abilities of a laminate trimmer. Who says they're only for laminate? Though limited to 1/4" shank bits, these trimmers are true routers. They're capable ofjoinery work and edge details just like a standard router, but also offer benefits not found on a standard router. Their small size makes them ideal for detail routing such as inlay work and small hardware installation. In addition, many of these routers are available as kits that include multiple specialty bases. Most kits include a traditional flat base and an offset base that allows a power transfer from the main spindle to an offset collet for routing into tight corners. A third base is a tilting base that allows routing at angles. This opens up lots of new opportunities for customized profiles, as well as angled grooves and more. The kits can almost double the price of the router, but it more than doubles the applications possible with the router, so it's worth considering. Testing To test the routers we used three different operations using new bits from Infinity Tools (infinitytools.com). We ran a 1/4"-radius roundover bit along the edge of an 18"-long Lyptus board, checking the amperage draw during the cut. One of the most common knocks against trim routers is that they're underpowered. To see if that by David Thiel David has been an editor with Popular Woodworking for more than 10 years and is also the host of Tools & Techniques on the DIY network. Comments or questions? Contact David at513-531-2690 ext. 1255 ordavid.thiel@fwpubs.com. / WJ 76 Popular Woodworking June 2006 |