Popular Woodworking 2006-08 № 156, страница 17

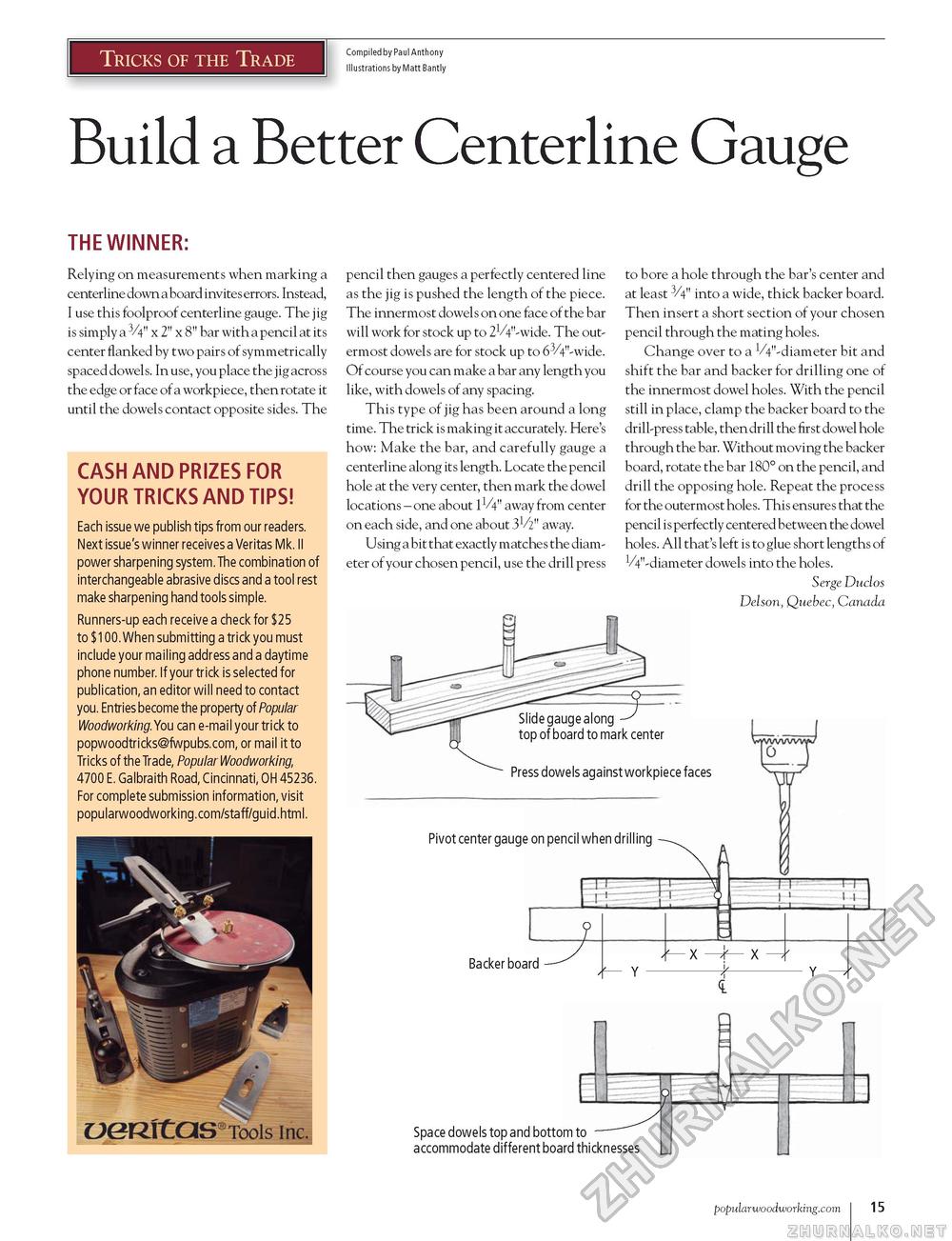

Tricks of the Trade Compiled by Paul Anthony Illustrations by Matt Bantly Build a Better Centerline Gauge THE WINNER: Relying on measurements when marking a centerline down a board invites errors. Instead, I use this foolproof centerline gauge. The jig is simply a V4" x 2" x 8" bar with a pencil at its center flanked by two pairs of symmetrically spaced dowels. In use, you place the jig across the edge or face of a workpiece, then rotate it until the dowels contact opposite sides. The CASH AND PRIZES FOR YOUR TRICKS AND TIPS! Each issue we publish tips from our readers. Next issue's winner receives a Veritas Mk. II power sharpening system. The combination of interchangeable abrasive discs and a tool rest make sharpening hand tools simple. Runners-up each receive a check for $25 to $100. When submitting a trick you must include your mailing address and a daytime phone number. If your trick is selected for publication, an editor will need to contact you. Entries become the property of Popular Woodworking. You can e-mail your trick to popwoodtricks@fwpubs.com, or mail it to Tricks of the Trade, Popular Woodworking, 4700 E. Galbraith Road, Cincinnati, OH 45236. For complete submission information, visit popularwoodworking.com/staff/guid.html. pencil then gauges a perfectly centered line as the jig is pushed the length of the piece. The innermost dowels on one face of the bar will work for stock up to 2}/4"-wide. The outermost dowels are for stock up to 63/4"-wide. Of course you can make a bar any length you like, with dowels of any spacing. This type of jig has been around a long time. The trick is making it accurately. Here's how: Make the bar, and carefully gauge a centerline along its length. Locate the pencil hole at the very center, then mark the dowel locations - one about lV4" away from center on each side, and one about 3V2" away. Using a bit that exactly matches the diameter of your chosen pencil, use the drill press to bore a hole through the bar's center and at least 3/4" into a wide, thick backer board. Then insert a short section of your chosen pencil through the mating holes. Change over to a ^"-diameter bit and shift the bar and backer for drilling one of the innermost dowel holes. With the pencil still in place, clamp the backer board to the drill-press table, then drill the first dowel hole through the bar. Without moving the backer board, rotate the bar 180° on the pencil, and drill the opposing hole. Repeat the process for the outermost holes. This ensures that the pencil is perfectly centered between the dowel holes. All that's left is to glue short lengths of VV-diameter dowels into the holes. Serge Duclos Delson, Quebec, Canada Slide gauge along top of board to mark center Press dowels against workpiece faces Pivot center gauge on pencil when drilling Backer board s Space dowels top and bottom to accommodate different board thicknesses M popularwoodworking.com I 15 |