Popular Woodworking 2006-08 № 156, страница 19

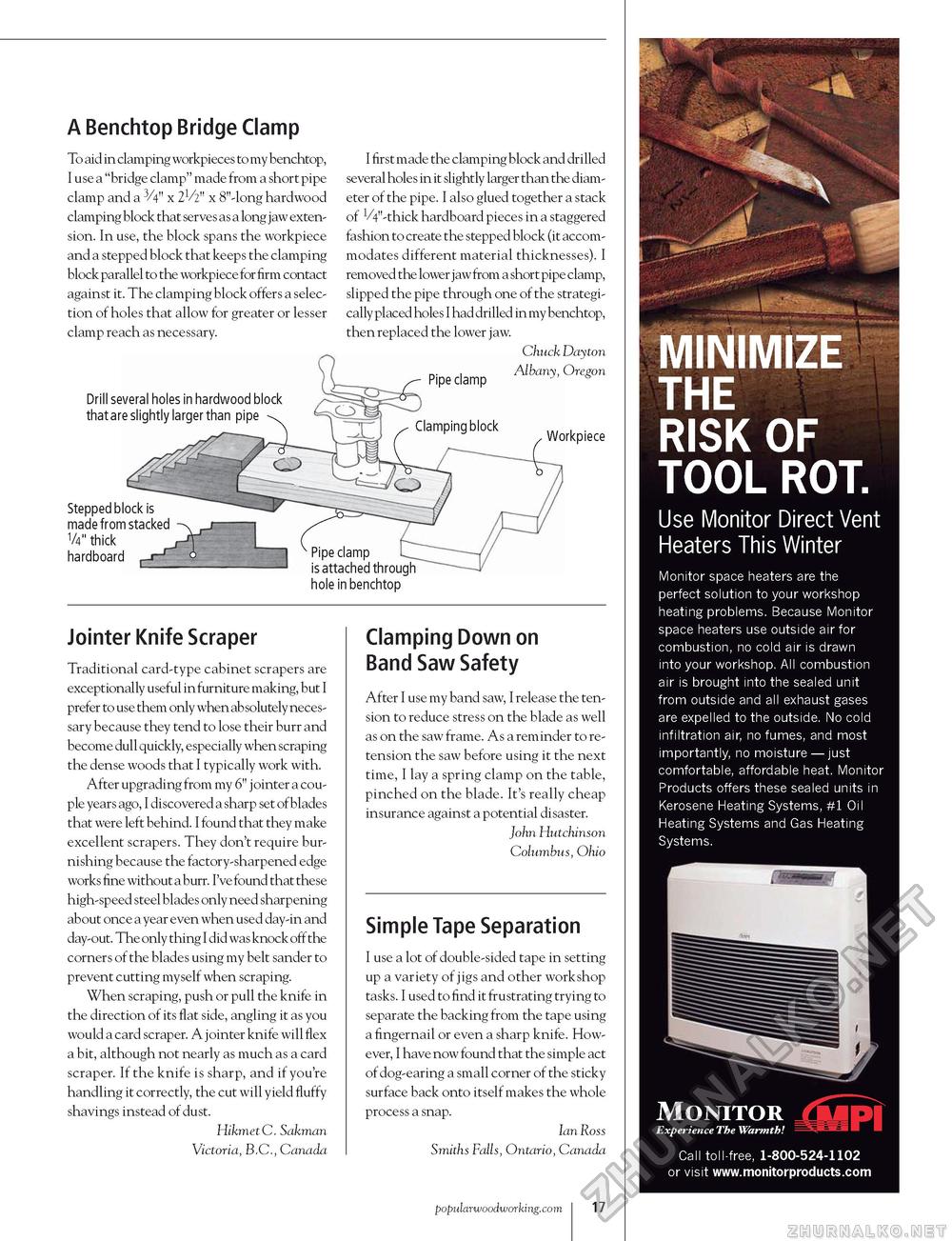

A Benchtop Bridge Clamp To aid in clamping workpieces to my benchtop, I use a "bridge clamp" made from a short pipe clamp and a 3/4" x 2V2" x 8"-long hardwood clamping block that serves as a long jaw extension. In use, the block spans the workpiece and a stepped block that keeps the clamping block parallel to the workpiece for firm contact against it. The clamping block offers a selection of holes that allow for greater or lesser clamp reach as necessary. Drill several holes in hardwood block that are slightly larger than pipe I first made the clamping block and drilled several holes in it slightly larger than the diameter of the pipe. I also glued together a stack of 4"-thick hardboard pieces in a staggered fashion to create the stepped block (it accommodates different material thicknesses). I removed the lower jaw from a short pipe clamp, slipped the pipe through one of the strategically placed holes I had drilled in my benchtop, then replaced the lower jaw. Chuck Dayton Albany, Oregon Pipe clamp Stepped block is made from stacked V4" thick hardboard Workpiece Pipe clamp is attached through hole in benchtop Jointer Knife Scraper Traditional card-type cabinet scrapers are exceptionally useful in furniture making, but I prefer to use them only when ab solutely necessary because they tend to lose their burr and become dull quickly, especially when scraping the dense woods that I typically work with. After upgrading from my 6" jointer a couple years ago, I discovered a sharp set ofblades that were left behind. I found that they make excellent scrapers. They don't require burnishing because the factory-sharpened edge works fine without a burr. I've found that these high-speed steel blades only need sharpening about once a year even when used day-in and day-out. The only thing I did was knock off the corners of the blades using my belt sander to prevent cutting myself when scraping. When scraping, push or pull the knife in the direction of its flat side, angling it as you would a card scraper. A jointer knife will flex a bit, although not nearly as much as a card scraper. If the knife is sharp, and if you're handling it correctly, the cut will yield fluffy shavings instead of dust. Hikmet C. Sakman Victoria, B.C., Canada Clamping Down on Band Saw Safety After I use my band saw, I release the tension to reduce stress on the blade as well as on the saw frame. As a reminder to re-tension the saw before using it the next time, I lay a spring clamp on the table, pinched on the blade. It's really cheap insurance against a potential disaster. John Hutchinson Columbus, Ohio Simple Tape Separation I use a lot of double-sided tape in setting up a variety of jigs and other workshop tasks. I used to find it frustrating trying to separate the backing from the tape using a fingernail or even a sharp knife. However, I have now found that the simple act of dog-earing a small corner of the sticky surface back onto itself makes the whole process a snap. Ian Ross Smiths Falls, Ontario, Canada MINIMIZE THE RISK OF TOOL ROT. Use Monitor Direct Vent Heaters This Winter Monitor space heaters are the perfect solution to your workshop heating problems. Because Monitor space heaters use outside air for combustion, no cold air is drawn into your workshop. All combustion air is brought into the sealed unit from outside and all exhaust gases are expelled to the outside. No cold infiltration air, no fumes, and most importantly, no moisture — just comfortable, affordable heat. Monitor Products offers these sealed units in Kerosene Heating Systems, #1 Oil Heating Systems and Gas Heating Systems. Monitor Experience The Warmth! Call toll-free, 1-800-524-1102 or visit www.monitorproducts.com popularwoodworking.com I 17 |