Popular Woodworking 2006-08 № 156, страница 36

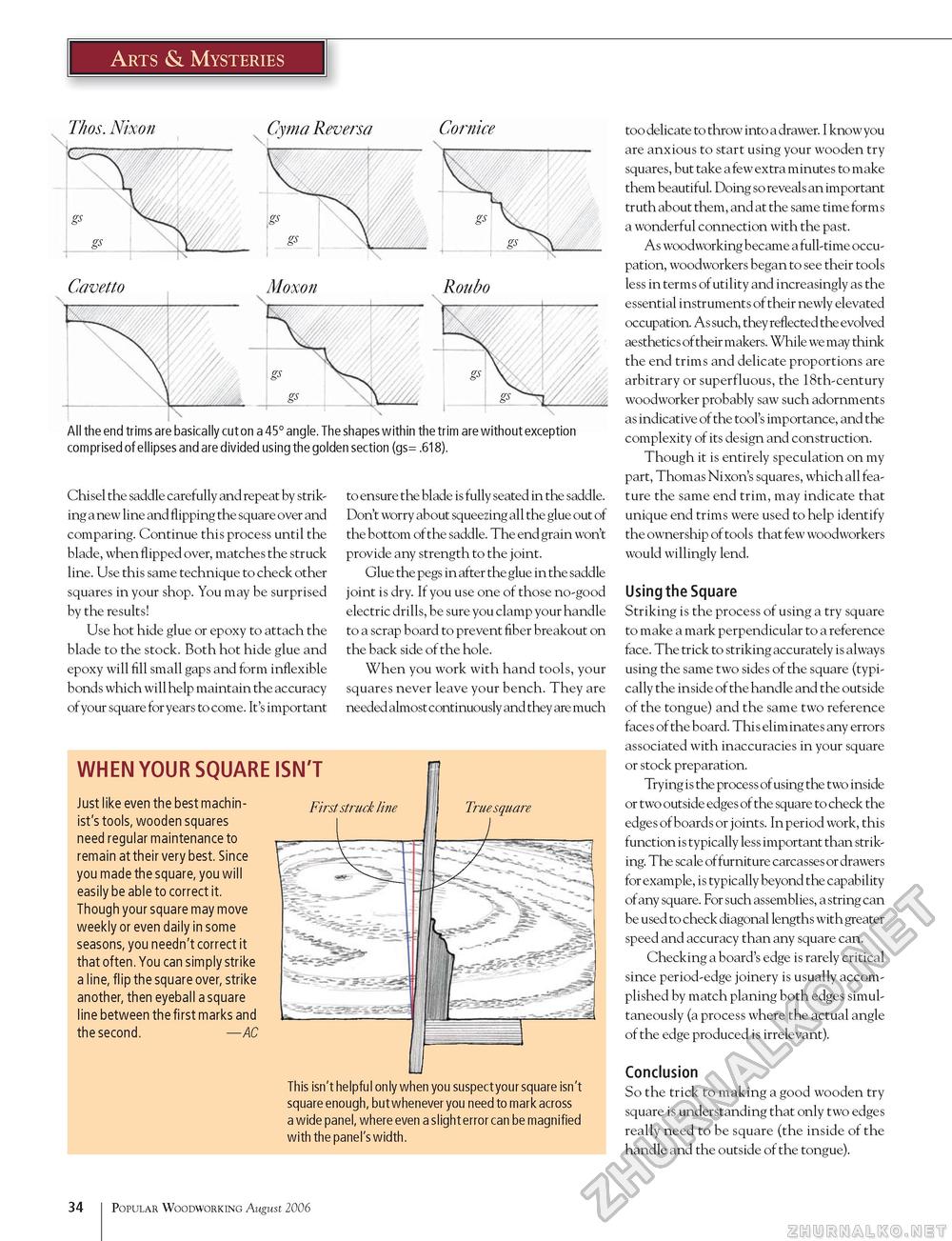

Arts & Mysteries Thos. Nixon Cyma Reversa Cornice

Moxon Roubo

All the end trims are basically cut on a 45° angle. The shapes within the trim are without exception comprised of ellipses and are divided using the golden section (gs= .618). Chisel the saddle carefully and repeat by striking a new line and flipping the square over and comparing. Continue this process until the blade, when flipped over, matches the struck line. Use this same technique to check other squares in your shop. You may be surprised by the results! Use hot hide glue or epoxy to attach the blade to the stock. Both hot hide glue and epoxy will fill small gaps and form inflexible bonds which will help maintain the accuracy of your square for years to come. It's important to ensure the blade is fully seated in the saddle. Don't worry about squeezing all the glue out of the bottom of the saddle. The end grain won't provide any strength to the joint. Glue the pegs in after the glue in the saddle joint is dry. If you use one of those no-good electric drills, be sure you clamp your handle to a scrap board to prevent fiber breakout on the back side of the hole. When you work with hand tools, your squares never leave your bench. They are needed almost continuously and they are much too delicate to throw into a drawer. I know you are anxious to start using your wooden try squares, but take a few extra minutes to make them beautiful. Doing so reveals an important truth about them, and at the same time forms a wonderful connection with the past. As woodworking became a full-time occupation, woodworkers began to see their tools less in terms of utility and increasingly as the essential instruments of their newly elevated occupation. As such, they reflected the evolved aesthetics of their makers. While we may think the end trims and delicate proportions are arbitrary or superfluous, the 18th-century woodworker probably saw such adornments as indicative of the tool's importance, and the complexity of its design and construction. Though it is entirely speculation on my part, Thomas Nixon's squares, which all feature the same end trim, may indicate that unique end trims were used to help identify the ownership of tools that few woodworkers would willingly lend. Using the Square Striking is the process of using a try square to make a mark perpendicular to a reference face. The trick to striking accurately is always using the same two sides of the square (typically the inside of the handle and the outside of the tongue) and the same two reference faces of the board. This eliminates any errors associated with inaccuracies in your square or stock preparation. Trying is the process of using the two inside or two outside edges of the square to check the edges ofboards or joints. In period work, this function is typically less important than striking. The scale of furniture carcasses or drawers for example, is typically beyond the capability of any square. For such assemblies, a string can be used to check diagonal lengths with greater speed and accuracy than any square can. Checking a board's edge is rarely critical since period-edge joinery is usually accomplished by match planing both edges simultaneously (a process where the actual angle of the edge produced is irrelevant). Conclusion So the trick to making a good wooden try square is understanding that only two edges really need to be square (the inside of the handle and the outside of the tongue). WHEN YOUR SQUARE ISN'T Just like even the best machinist's tools, wooden squares need regular maintenance to remain at their very best. Since you made the square, you will easily be able to correct it. Though your square may move weekly or even daily in some seasons, you needn't correct it that often. You can simply strike a line, flip the square over, strike another, then eyeball a square line between the first marks and the second. — AC This isn't helpful only when you suspect your square isn't square enough, but whenever you need to mark across a wide panel, where even a slight error can be magnified with the panel's width. 34 Popular Woodworking August 2006 |