Popular Woodworking 2006-10 № 157, страница 41

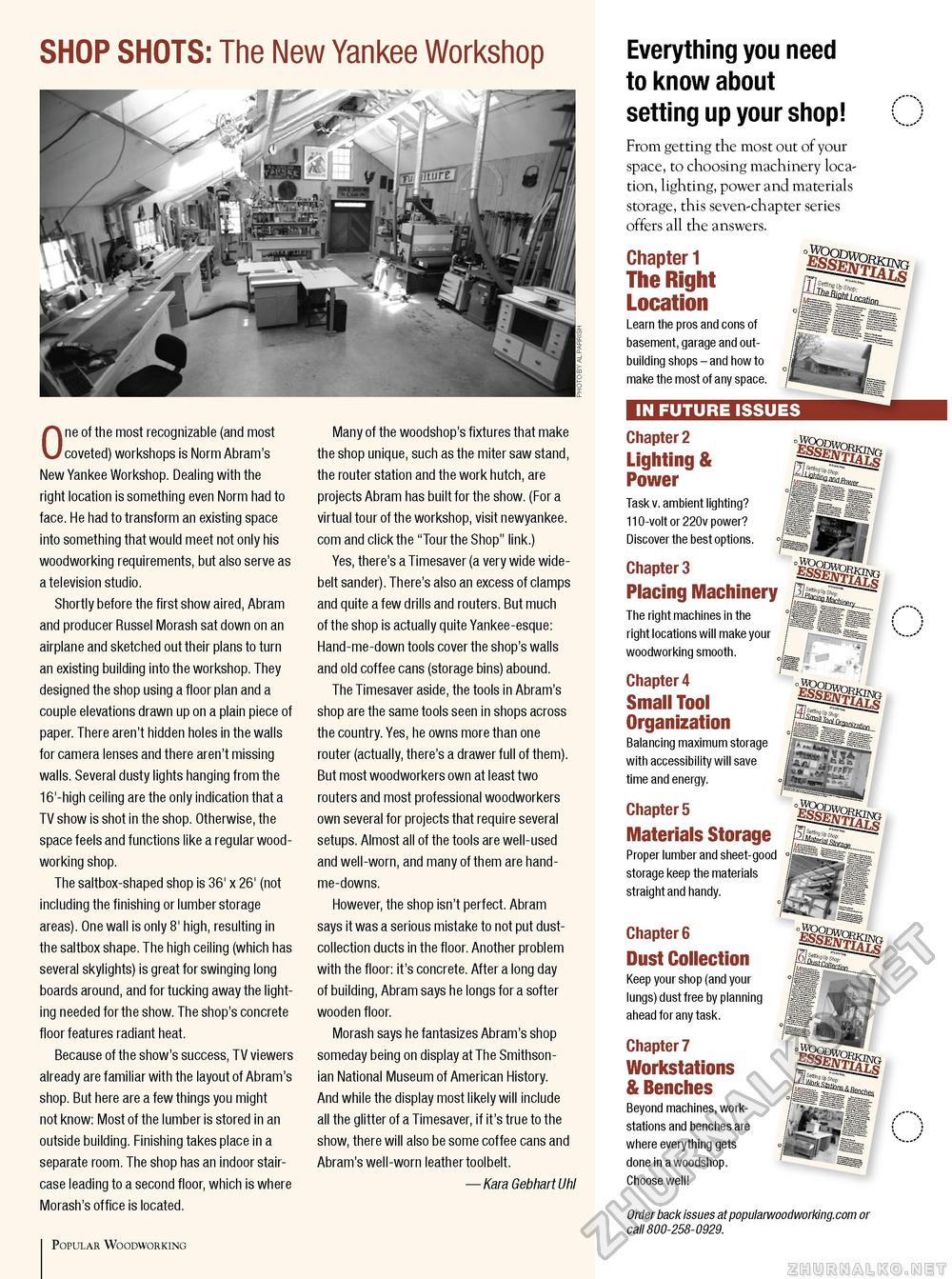

SHOP SHOTS: The New Yankee Workshop One of the most recognizable (and most coveted) workshops is Norm Abram's New Yankee Workshop. Dealing with the right location is something even Norm had to face. He had to transform an existing space into something that would meet not only his woodworking requirements, but also serve as a television studio. Shortly before the first show aired, Abram and producer Russel Morash sat down on an airplane and sketched out their plans to turn an existing building into the workshop. They designed the shop using a floor plan and a couple elevations drawn up on a plain piece of paper. There aren't hidden holes in the walls for camera lenses and there aren't missing walls. Several dusty lights hanging from the 16'-high ceiling are the only indication that a TV show is shot in the shop. Otherwise, the space feels and functions like a regular woodworking shop. The saltbox-shaped shop is 36' x 26' (not including the finishing or lumber storage areas). One wall is only 8' high, resulting in the saltbox shape. The high ceiling (which has several skylights) is great for swinging long boards around, and for tucking away the lighting needed for the show. The shop's concrete floor features radiant heat. Because of the show's success, TV viewers already are familiar with the layout of Abram's shop. But here are a few things you might not know: Most of the lumber is stored in an outside building. Finishing takes place in a separate room. The shop has an indoor staircase leading to a second floor, which is where Morash's office is located. Popular Woodworking Many of the woodshop's fixtures that make the shop unique, such as the miter saw stand, the router station and the work hutch, are projects Abram has built for the show. (For a virtual tour of the workshop, visit newyankee. com and click the "Tour the Shop" link.) Yes, there's a Timesaver (a very wide wide-belt sander). There's also an excess of clamps and quite a few drills and routers. But much of the shop is actually quite Yankee-esque: Hand-me-down tools cover the shop's walls and old coffee cans (storage bins) abound. The Timesaver aside, the tools in Abram's shop are the same tools seen in shops across the country. Yes, he owns more than one router (actually, there's a drawer full of them). But most woodworkers own at least two routers and most professional woodworkers own several for projects that require several setups. Almost all of the tools are well-used and well-worn, and many of them are hand-me-downs. However, the shop isn't perfect. Abram says it was a serious mistake to not put dust-collection ducts in the floor. Another problem with the floor: it's concrete. After a long day of building, Abram says he longs for a softer wooden floor. Morash says he fantasizes Abram's shop someday being on display at The Smithsonian National Museum of American History. And while the display most likely will include all the glitter of a Timesaver, if it's true to the show, there will also be some coffee cans and Abram's well-worn leather toolbelt. — Kara Gebhart Uhl Everything you need to know about setting up your shop! From getting the most out of your space, to choosing machinery location, lighting, power and materials storage, this seven-chapter series offers all the answers. Chapter 1 The Right Location Learn the pros and cons of basement, garage and outbuilding shops - and how to make the most of any space. IN FUTURE ISSUES Chapter 2 Lighting & Power Task v. ambient lighting? 110-volt or 220v power? Discover the best options. Chapter 3 Placing Machinery The right machines in the right locations will make your woodworking smooth. c Chapter 4 Small Tool Organization Balancing maximum storage with accessibility will save time and energy. ■ Chapter 5 Materials Storage Proper lumber and sheet-good storage keep the materials straight and handy. Chapter 6 Dust Collection Keep your shop (and your lungs) dust free by planning ahead for any task. Chapter 7 Workstations & Benches Beyond machines, workstations and benches are where everything gets < done in a woodshop. Choose well! Order back issues at popularwoodworking.com or call 800-258-0929. |