Popular Woodworking 2006-10 № 157, страница 46

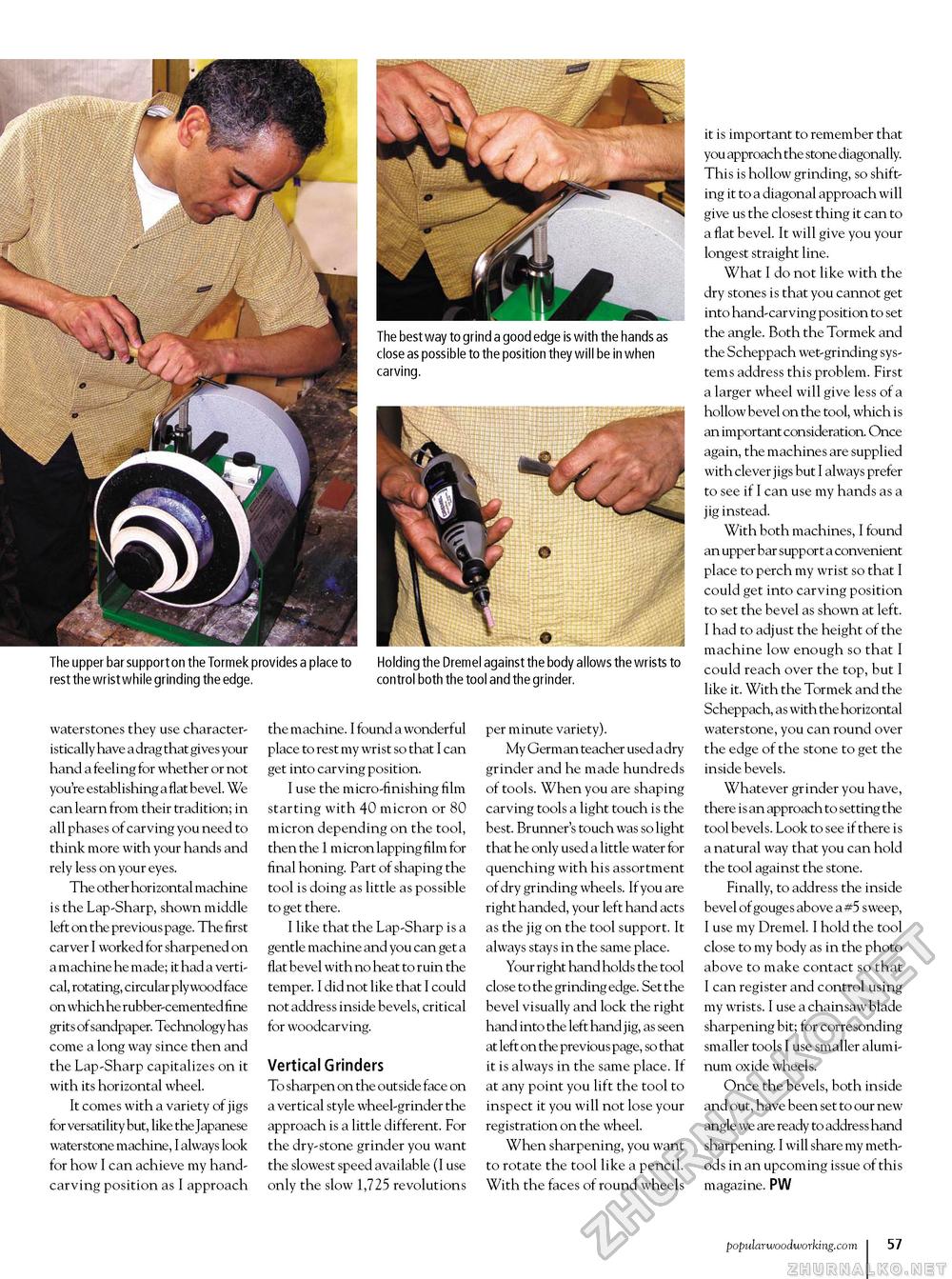

The best way to grind a good edge is with the hands as close as possible to the position they will be in when carving. The upper bar support on the Tormek provides a place to Holding the Dremel against the body allows the wrists to rest the wrist while grinding the edge. control both the tool and the grinder. waterstones they use characteristically have a drag that gives your hand a feeling for whether or not you're establishing a flat bevel. We can learn from their tradition; in all phases of carving you need to think more with your hands and rely less on your eyes. The other horizontal machine is the Lap-Sharp, shown middle left on the previous page. The first carver I worked for sharpened on a machine he made; it had a vertical, rotating, circular plywood face on which he rubber-cemented fine grits of sandpaper. Technology has come a long way since then and the Lap-Sharp capitalizes on it with its horizontal wheel. It comes with a variety of jigs for versatility but, like the Japanese waterstone machine, I always look for how I can achieve my hand-carving position as I approach the machine. I found a wonderful place to rest my wrist so that I can get into carving position. I use the micro-finishing film starting with 40 micron or 80 micron depending on the tool, then the 1 micron lapping film for final honing. Part of shaping the tool is doing as little as possible to get there. I like that the Lap-Sharp is a gentle machine and you can get a flat bevel with no heat to ruin the temper. I did not like that I could not address inside bevels, critical for woodcarving. Vertical Grinders To sharpen on the outside face on a vertical style wheel-grinder the approach is a little different. For the dry-stone grinder you want the slowest speed available (I use only the slow 1,725 revolutions per minute variety). My German teacher used a dry grinder and he made hundreds of tools. When you are shaping carving tools a light touch is the best. Brunner's touch was so light that he only used a little water for quenching with his assortment of dry grinding wheels. If you are right handed, your left hand acts as the jig on the tool support. It always stays in the same place. Your right hand holds the tool close to the grinding edge. Set the bevel visually and lock the right hand into the left hand j ig, as seen at left on the previous page, so that it is always in the same place. If at any point you lift the tool to inspect it you will not lose your registration on the wheel. When sharpening, you want to rotate the tool like a pencil. With the faces of round wheels it is important to remember that you approach the stone diagonally. This is hollow grinding, so shifting it to a diagonal approach will give us the closest thing it can to a flat bevel. It will give you your longest straight line. What I do not like with the dry stones is that you cannot get into hand-carving position to set the angle. Both the Tormek and the Scheppach wet-grinding systems address this problem. First a larger wheel will give less of a hollow bevel on the tool, which is an important consideration. Once again, the machines are supplied with clever jigs but I always prefer to see if I can use my hands as a jig instead. With both machines, I found an upper bar support a convenient place to perch my wrist so that I could get into carving position to set the bevel as shown at left. I had to adjust the height of the machine low enough so that I could reach over the top, but I like it. With the Tormek and the Scheppach, as with the horizontal waterstone, you can round over the edge of the stone to get the inside bevels. Whatever grinder you have, there is an approach to setting the tool bevels. Look to see if there is a natural way that you can hold the tool against the stone. Finally, to address the inside bevel of gouges above a #5 sweep, I use my Dremel. I hold the tool close to my body as in the photo above to make contact so that I can register and control using my wrists. I use a chainsaw blade sharpening bit; for corresonding smaller tools I use smaller aluminum oxide wheels. Once the bevels, both inside and out, have been set to our new angle we are ready to address hand sharpening. I will share my methods in an upcoming issue of this magazine. PW popularwoodworking.com i 57 |