Popular Woodworking 2006-12 № 159, страница 10

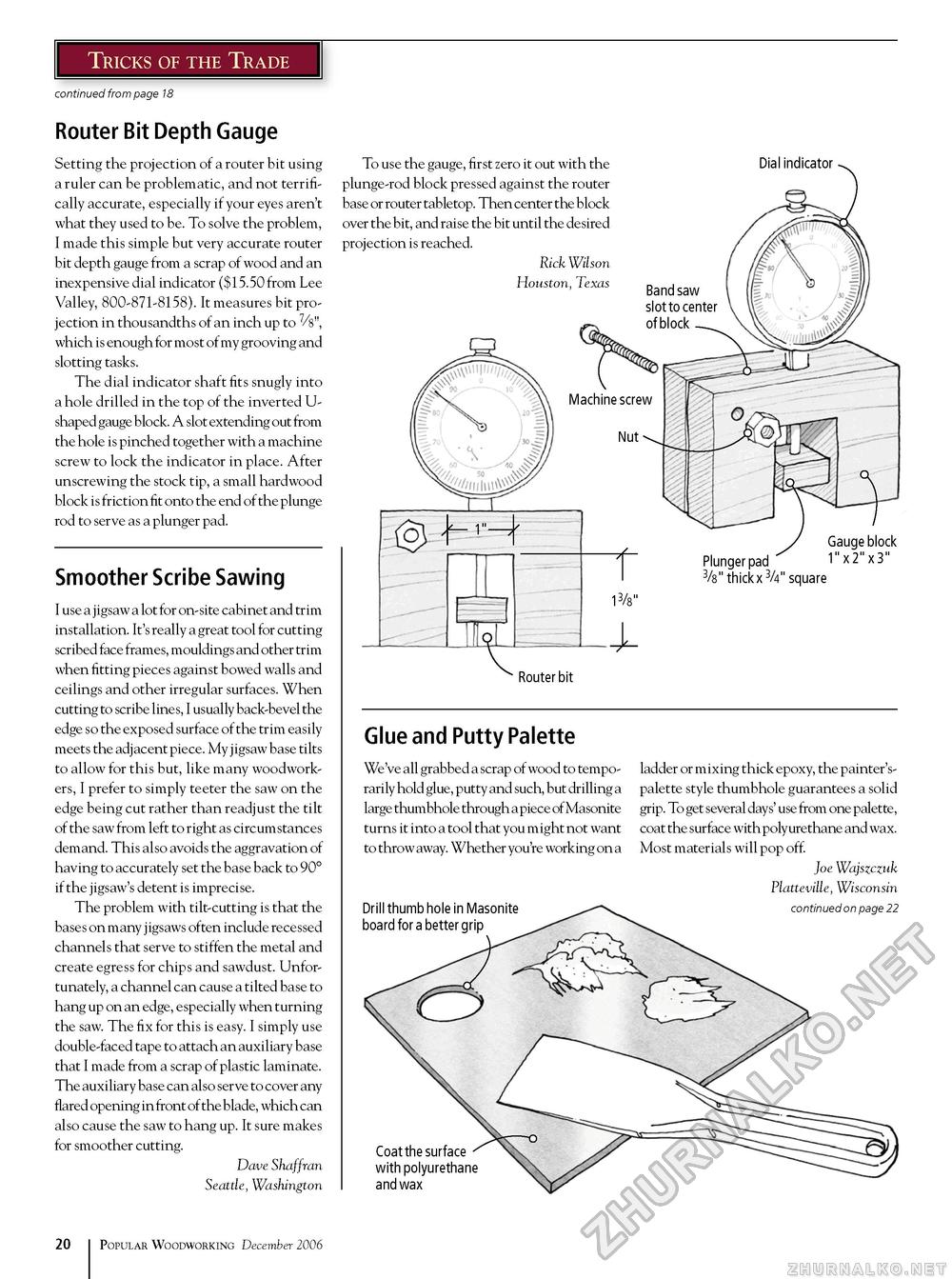

Dial indicator ■ Gauge block Plunger pad ' 1" x 2" x 3" 3/s" thick x 3A" square Tricks of the Trade continued from page 18 Router Bit Depth Gauge Setting the projection of a router bit using a ruler can be problematic, and not terrifically accurate, especially if your eyes aren't what they used to be. To solve the problem, I made this simple but very accurate router bit depth gauge from a scrap of wood and an inexpensive dial indicator ($15.50 from Lee Valley, 800-871-8158). It measures bit projection in thousandths of an inch up to 7/8", which is enough for most of my grooving and slotting tasks. The dial indicator shaft fits snugly into a hole drilled in the top of the inverted U-shaped gauge block. A slot extending out from the hole is pinched together with a machine screw to lock the indicator in place. After unscrewing the stock tip, a small hardwood block is friction fit onto the end of the plunge rod to serve as a plunger pad. Smoother Scribe Sawing I use a jigsaw a lot for on-site cabinet and trim installation. It's really a great tool for cutting scribed face frames, mouldings and other trim when fitting pieces against bowed walls and ceilings and other irregular surfaces. When cutting to scribe lines, I usually back-bevel the edge so the exposed surface of the trim easily meets the adjacent piece. My jigsaw base tilts to allow for this but, like many woodworkers, I prefer to simply teeter the saw on the edge being cut rather than readjust the tilt of the saw from left to right as circumstances demand. This also avoids the aggravation of having to accurately set the base back to 90° if the jigsaw's detent is imprecise. The problem with tilt-cutting is that the bases on many jigsaws often include recessed channels that serve to stiffen the metal and create egress for chips and sawdust. Unfortunately, a channel can cause a tilted base to hang up on an edge, especially when turning the saw. The fix for this is easy. I simply use double-faced tape to attach an auxiliary base that I made from a scrap of plastic laminate. The auxiliary base can also serve to cover any flared opening in front of the blade, which can also cause the saw to hang up. It sure makes for smoother cutting. Dave Shaffran Seattle, Washington To use the gauge, first zero it out with the plunge-rod block pressed against the router base or router table top. Then center the block over the bit, and raise the bit until the desired projection is reached. Rick Wilson Houston, Texas Glue and Putty Palette We've all grabbed a scrap of wood to temporarily hold glue, putty and such, but drilling a large thumbhole through a piece of Masonite turns it into a tool that you m ight not want to throw away. Whether you're working on a ladder or mixing thick epoxy, the painter's-palette style thumbhole guarantees a solid grip. To get several days' use from one palette, coat the surface with polyurethane and wax. Most materials will pop off. Joe Wajszczuk Platteville, Wisconsin Drill thumb hole in Masonite board for a better grip continued on page 22 Coat the surface with polyurethane and wax 20 Popular Woodworking December 2006 |