Popular Woodworking 2006-12 № 159, страница 12

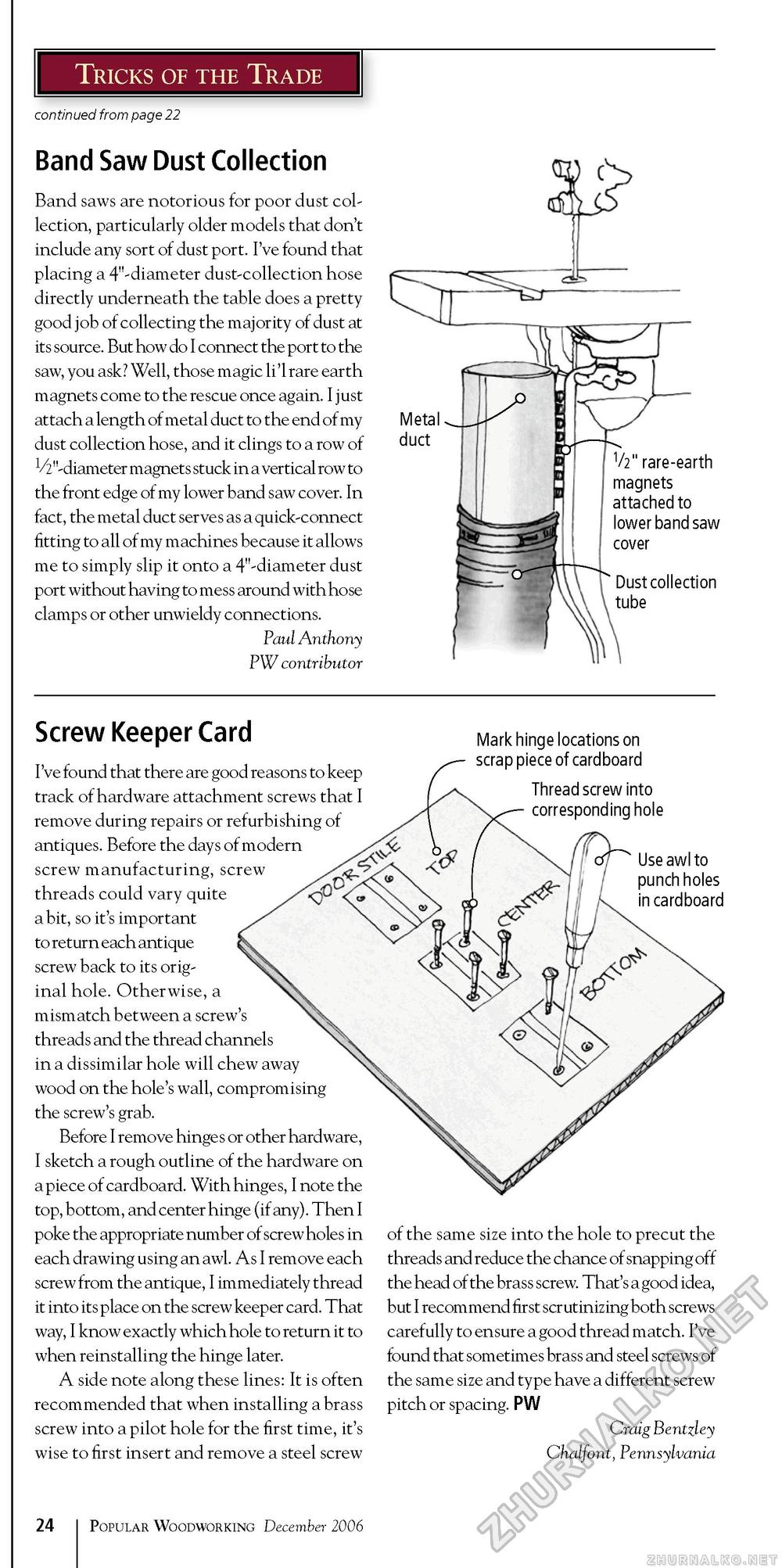

Tricks of the Trade continued from page 22 Band Saw Dust Collection Band saws are notorious for poor dust collection, particularly older models that don't include any sort of dust port. I've found that placing a 4"-diameter dust-collection hose directly underneath the table does a pretty good job of collecting the majority of dust at its source. But how do I connect the port to the saw, you ask? Well, those magic li'l rare earth magnets come to the rescue once again. I just attach a length of metal duct to the end of my dust collection hose, and it clings to a row of V2"-diameter magnets stuck in a vertical row to the front edge of my lower band saw cover. In fact, the metal duct serves as a quick-connect fitting to all of my machines because it allows me to simply slip it onto a 4"-diameter dust port without having to mess around with hose clamps or other unwieldy connections. Paul Anthony PW contributor Screw Keeper Card I've found that there are good reasons to keep track of hardware attachment screws that I remove during repairs or refurbishing of antiques. Before the days of modern screw manufacturing, screw . - " threads could vary quite a bit, so it's important to return each antique screw back to its original hole. Otherwise, a mismatch between a screw's threads and the thread channels in a dissimilar hole will chew away wood on the hole's wall, compromising the screw's grab. Before I remove hinges or other hardware, I sketch a rough outline of the hardware on a piece of cardboard. With hinges, I note the top, bottom, and center hinge (if any). Then I poke the appropriate number of screw holes in each drawing using an awl. As I remove each screw from the antique, I immediately thread it into its place on the screw keeper card. That way, I know exactly which hole to return it to when reinstalling the hinge later. A side note along these lines: It is often recommended that when installing a brass screw into a pilot hole for the first time, it's wise to first insert and remove a steel screw Mark hinge locations on scrap piece of cardboard Thread screw into corresponding hole Use awl to punch holes in cardboard of the same size into the hole to precut the threads and reduce the chance of snapping off the head of the brass screw. That's a good idea, but I recommend first scrutinizing both screws carefully to ensure a good thread match. I've found that sometimes brass and steel screws of the same size and type have a different screw pitch or spacing. PW Craig Bentzley Chalfont, Pennsylvania 24 Popular Woodworking December 2006 |