Popular Woodworking 2007-02 № 160, страница 28

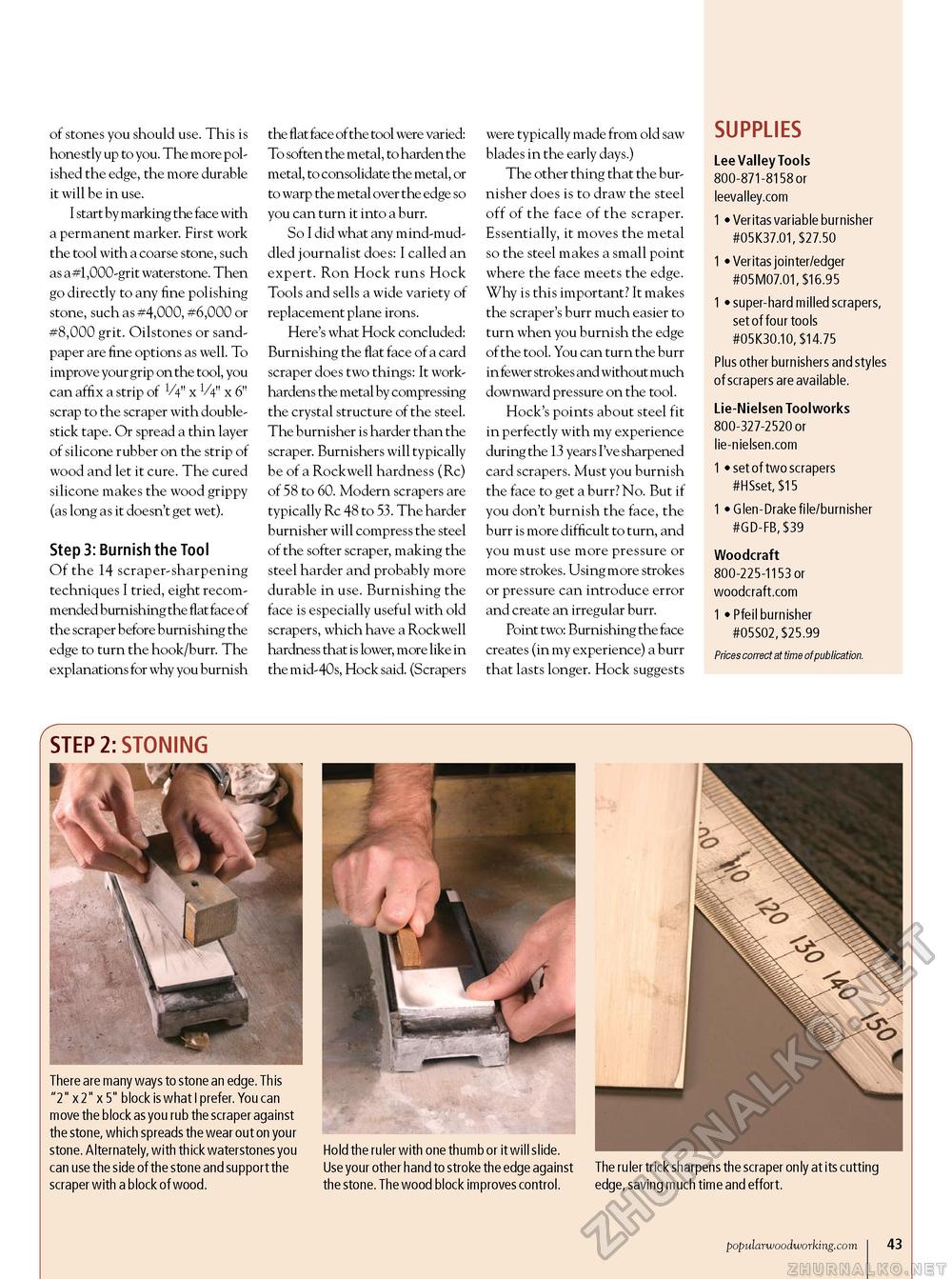

of stones you should use. This is honestly up to you. The more polished the edge, the more durable it will be in use. I start by marking the face with a permanent marker. First work the tool with a coarse stone, such as a #1,000-grit waterstone. Then go directly to any fine polishing stone, such as #4,000, #6,000 or #8,000 grit. Oilstones or sandpaper are fine options as well. To improve your grip on the tool, you can affix a strip of V4" x V4" x 6" scrap to the scraper with double-stick tape. Or spread a thin layer of silicone rubber on the strip of wood and let it cure. The cured silicone makes the wood grippy (as long as it doesn't get wet). Step 3: Burnish the Tool Of the 14 scraper-sharpening techniques I tried, eight recommended burnishing the flat face of the scraper before burnishing the edge to turn the hook/burr. The explanations for why you burnish the flat face of the tool were varied: To soften the metal, to harden the metal, to consolidate the metal, or to warp the metal over the edge so you can turn it into a burr. So I did what any mind-muddled journalist does: I called an expert. Ron Hock runs Hock Tools and sells a wide variety of replacement plane irons. Here's what Hock concluded: Burnishing the flat face of a card scraper does two things: It work-hardens the metal by compressing the crystal structure of the steel. The burnisher is harder than the scraper. Burnishers will typically be of a Rockwell hardness (Rc) of 58 to 60. Modern scrapers are typically Rc 48 to 53. The harder burnisher will compress the steel of the softer scraper, making the steel harder and probably more durable in use. Burnishing the face is especially useful with old scrapers, which have a Rockwell hardness that is lower, more like in the mid-40s, Hock said. (Scrapers were typically made from old saw blades in the early days.) The other thing that the burnisher does is to draw the steel off of the face of the scraper. Essentially, it moves the metal so the steel makes a small point where the face meets the edge. Why is this important? It makes the scraper's burr much easier to turn when you burnish the edge of the tool. You can turn the burr in fewer strokes and without much downward pressure on the tool. Hock's points about steel fit in perfectly with my experience during the 13 years I've sharpened card scrapers. Must you burnish the face to get a burr? No. But if you don't burnish the face, the burr is more difficult to turn, and you must use more pressure or more strokes. Using more strokes or pressure can introduce error and create an irregular burr. Point two: Burnishing the face creates (in my experience) a burr that lasts longer. Hock suggests supplies Lee Valley Tools 800-871-8158 or leevalley.com 1 • Veritas variable burnisher #05K37.01, $27.50 1 • Veritas jointer/edger #05M07.01, $16.95 1 • super-hard milled scrapers, set of four tools #05K30.10, $14.75 Plus other burnishers and styles of scrapers are available. Lie-Nielsen Toolworks 800-327-2520 or lie-nielsen.com 1 • set of two scrapers #HSset, $15 1 • Glen-Drake file/burnisher #GD-FB, $39 Woodcraft 800-225-1153 or woodcraft.com 1 • Pfeil burnisher #05S02, $25.99 Prices correct at time of publication. STEP 2: STONING There are many ways to stone an edge. Th is "2" x 2" x 5" block is what I prefer. You can move the block as you rub the scraper against the stone, which spreads the wear out on your stone. Alternately, with thick waterstones you can use the side of the stone and support the scraper with a block of wood. Hold the ruler with one thumb or it will slide. Use your other hand to stroke the edge against The ruler trick sharpens the scraper on ly at its cutting the stone. The wood block improves control. edge, saving much time and effort. popularwoodworking.com 31 |