Popular Woodworking 2007-02 № 160, страница 27

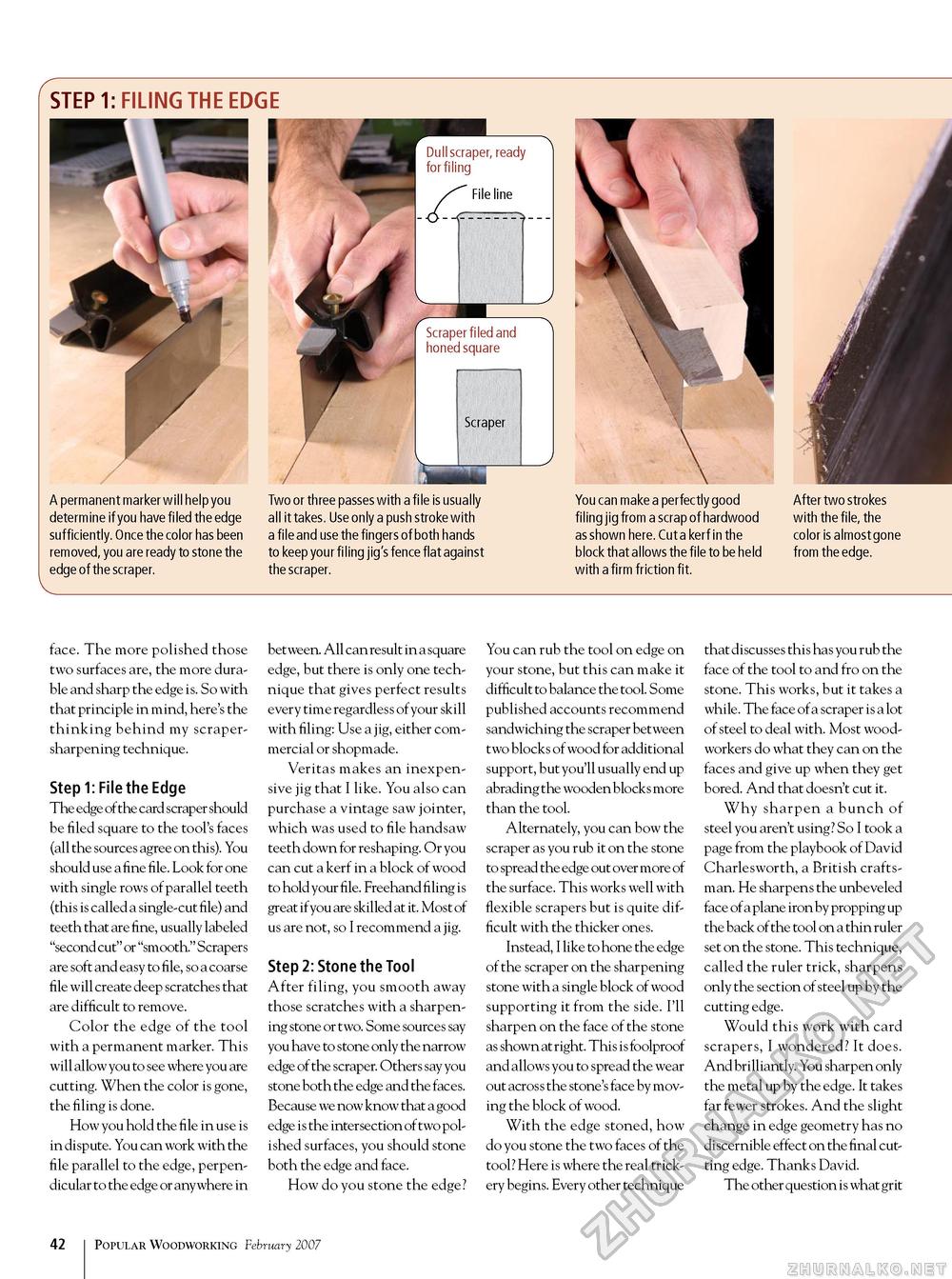

STEP 1: FILING THE EDGE

Scraper filed and honed square A permanent marker will help you determine if you have fi led the edge sufficiently. Once the color has been removed, you are ready to stone the edge of the scraper. Two or three passes with a file is usually all it takes. Use only a push stroke with a file and use the fingers of both hands to keep your filing jig's fence flat against the scraper. You can make a perfectly good filing jig from a scrap of hardwood as shown here. Cut a kerf in the block that allows the file to be held with a firm friction fit. After two strokes with the file, the color is almost gone from the edge. face. The more polished those two surfaces are, the more durable and sharp the edge is. So with that principle in mind, here's the thinking behind my scraper-sharpening technique. Step 1: File the Edge The edge of the card scraper should be filed square to the tool's faces (all the sources agree on this). You should use a fine file. Look for one with single rows of parallel teeth (this is called a single-cut file) and teeth that are fine, usually labeled "second cut" or "smooth." Scrapers are soft and easy to file, so a coarse file will create deep scratches that are difficult to remove. Color the edge of the tool with a permanent marker. This will allow you to see where you are cutting. When the color is gone, the filing is done. How you hold the file in use is in dispute. You can work with the file parallel to the edge, perpendicular to the edge or anywhere in between. All can result in a square edge, but there is only one technique that gives perfect results every time regardless of your skill with filing: Use a jig, either commercial or shopmade. Veritas makes an inexpensive jig that I like. You also can purchase a vintage saw jointer, which was used to file handsaw teeth down for reshaping. Or you can cut a kerf in a block of wood to hold your file. Freehand filing is great if you are skilled at it. Most of us are not, so I recommend a jig. Step 2: Stone the Tool After filing, you smooth away those scratches with a sharpening stone or two. Some sources say you have to stone only the narrow edge of the scraper. Others say you stone both the edge and the faces. Because we now know that a good edge is the intersection of two polished surfaces, you should stone both the edge and face. How do you stone the edge? You can rub the tool on edge on your stone, but this can make it difficult to balance the tool. Some published accounts recommend sandwiching the scraper between two blocks of wood for additional support, but you'll usually end up abrading the wooden blocks more than the tool. Alternately, you can bow the scraper as you rub it on the stone to spread the edge out over more of the surface. This works well with flexible scrapers but is quite difficult with the thicker ones. Instead, I like to hone the edge of the scraper on the sharpening stone with a single block of wood supporting it from the side. I'll sharpen on the face of the stone as shown at right. This is foolproof and allows you to spread the wear out across the stone's face by moving the block of wood. With the edge stoned, how do you stone the two faces of the tool? Here is where the real trickery begins. Every other technique that discusses this has you rub the face of the tool to and fro on the stone. This works, but it takes a while. The face of a scraper is a lot of steel to deal with. Most woodworkers do what they can on the faces and give up when they get bored. And that doesn't cut it. Why sharpen a bunch of steel you aren't using? So I took a page from the playbook of David Charlesworth, a British craftsman. He sharpens the unbeveled face of a plane iron by propping up the back of the tool on a thin ruler set on the stone. This technique, called the ruler trick, sharpens only the section of steel up by the cutting edge. Would this work with card scrapers, I wondered? It does. And brilliantly. You sharpen only the metal up by the edge. It takes far fewer strokes. And the slight change in edge geometry has no discernible effect on the final cutting edge. Thanks David. The other question is what grit 10 Popular Woodworking February 2007 |

||||||||||||||||||