Popular Woodworking 2007-02 № 160, страница 6

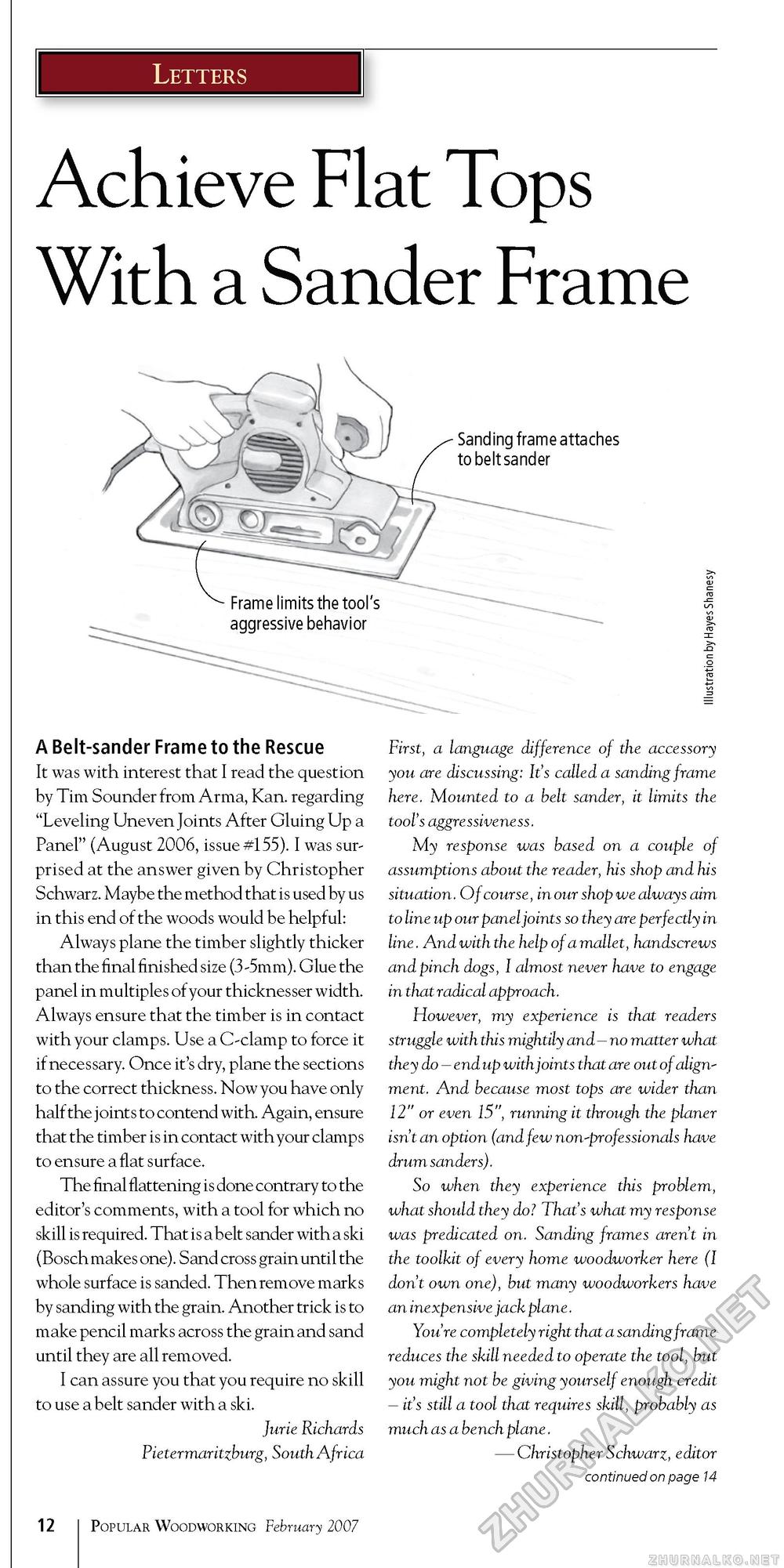

Letters Achieve Flat Tops With a Sander Frame Sanding frame attaches to belt sander Frame limits the tool's aggressive behavior A Belt-sander Frame to the Rescue It was with interest that I read the question by Tim Sounder from Arma, Kan. regarding "Leveling Uneven Joints After Gluing Up a Panel" (August 2006, issue #155). I was surprised at the answer given by Christopher Schwarz. Maybe the method that is used by us in this end of the woods would be helpful: Always plane the timber slightly thicker than the final finished size (3 -5mm). Glue the panel in multiples of your thicknesser width. Always ensure that the timber is in contact with your clamps. Use a C-clamp to force it if necessary. Once it's dry, plane the sections to the correct thickness. Now you have only half the joints to contend with. Again, ensure that the timber is in contact with your clamps to ensure a flat surface. The final flattening is done contrary to the editor's comments, with a tool for which no skill is required. That is a belt sander with a ski (Bosch makes one). Sand cross grain until the whole surface is sanded. Then remove marks by sanding with the grain. Another trick is to make pencil marks across the grain and sand until they are all removed. I can assure you that you require no skill to use a belt sander with a ski. Jurie Richards Pietermaritzburg, South Africa First, a language difference of the accessory you are discussing: It's called a sanding frame here. Mounted to a belt sander, it limits the tool's aggressiveness. My response was based on a couple of assumptions about the reader, his shop and his situation. Of course, in our shop we always aim to line up our panel joints so they are perfectly in line. And with the help of a mallet, handscrews and pinch dogs, I almost never have to engage in that radical approach. However, my experience is that readers struggle with this mightily and—no matter what they do — end up with joints that are out of align-ment. And because most tops are wider than 12" or even 15", running it through the planer isn't an option (and few non-professionals have drum sanders). So when they experience this problem, what should they do? That's what my response was predicated on. Sanding frames arent in the toolkit of every home woodworker here (I don't own one), but many woodworkers have an inexpensive jack plane. You're completely right that a sanding frame reduces the skill needed to operate the tool, but you might not be giving yourself enough credit — it's still a tool that requires skill, probably as much as a bench plane. — Christopher Schwarz, editor continued on page 14 12 Popular Woodworking February 2007 |