Popular Woodworking 2007-02 № 160, страница 66

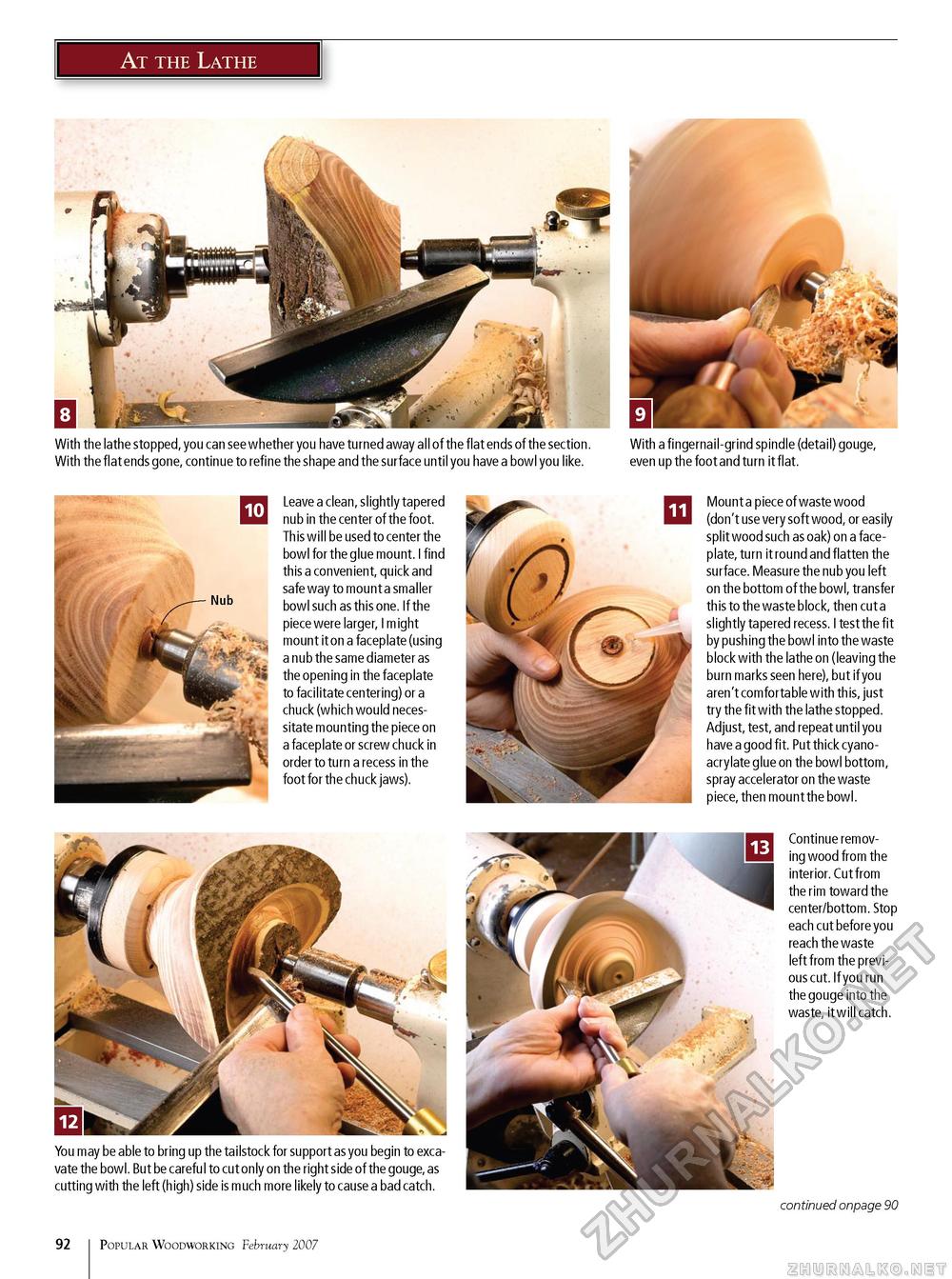

At the Lathe With the lathe stopped, you can see whether you have turned away all of the flat ends of the section. With the flat ends gone, continue to refine the shape and the surface until you have a bowl you like. With a fingernail-grind spindle (detail) gouge, even up the foot and turn it flat. Nub Leave a clean, slightly tapered nub in the center of the foot. This will be used to center the bowl for the glue mount. I find this a convenient, quick and safe way to mount a smaller bowl such as this one. If the piece were larger, I might mount it on a faceplate (using a nub the same diameter as the opening in the faceplate to facilitate centering) or a chuck (which would necessitate mounting the piece on a faceplate or screw chuck in order to turn a recess in the foot for the chuck jaws). You may be able to bring up the tailstock for support as you begin to excavate the bowl. But be careful to cut only on the right side of the gouge, as cutting with the left (high) side is much more likely to cause a bad catch. Mount a piece of waste wood (don't use very soft wood, or easily split wood such as oak) on a faceplate, turn it round and flatten the surface. Measure the nub you left on the bottom of the bowl, transfer this to the waste block, then cut a slightly tapered recess. I test the fit by pushing the bowl into the waste block with the lathe on (leaving the burn marks seen here), but if you aren't comfortable with this, just try the fit with the lathe stopped. Adjust, test, and repeat until you have a good fit. Put thick cyano-acrylate glue on the bowl bottom, spray accelerator on the waste piece, then mount the bowl. Continue removing wood from the interior. Cut from the rim toward the center/bottom. Stop each cut before you reach the waste left from the previous cut. If you run the gouge into the waste, it will catch. continued onpage 90 90 Popular Woodworking February 2007 |