Popular Woodworking 2007-02 № 160, страница 67

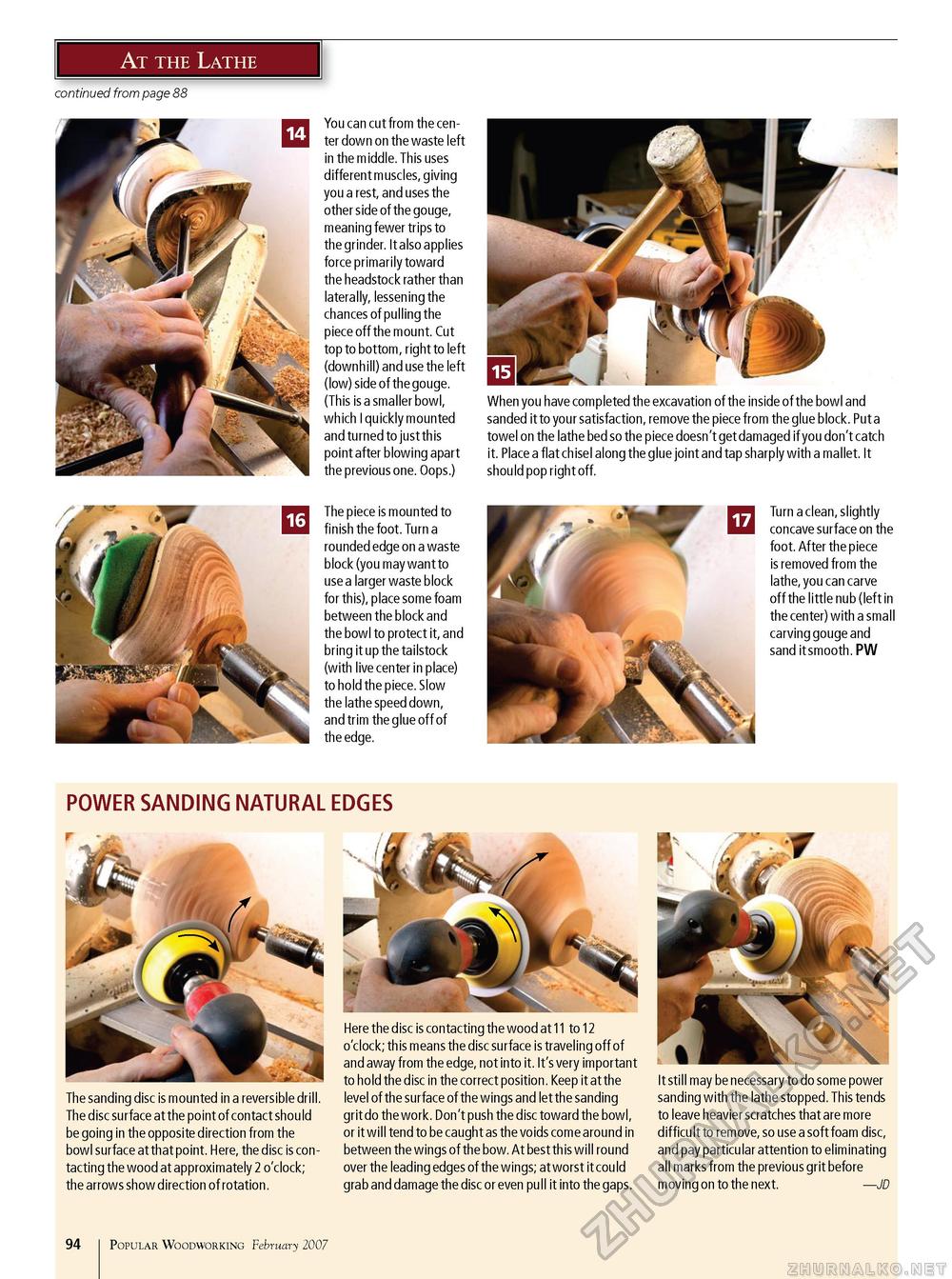

At the Lathe continued from page 88 You can cut from the center down on the waste left in the middle. This uses different muscles, giving you a rest, and uses the other side of the gouge, meaning fewer trips to the grinder. It also applies force primarily toward the headstock rather than laterally, lessening the chances of pulling the piece off the mount. Cut top to bottom, right to left (downhill) and use the left (low) side of the gouge. (This is a smaller bowl, which I quickly mounted and turned to just this point after blowing apart the previous one. Oops.) The piece is mounted to finish the foot. Turn a rounded edge on a waste block (you may want to use a larger waste block for this), place some foam between the block and the bowl to protect it, and bring it up the tailstock (with live center in place) to hold the piece. Slow the lathe speed down, and trim the glue off of the edge. When you have completed the excavation of the inside of the bowl and sanded it to your satisfaction, remove the piece from the glue block. Put a towel on the lathe bed so the piece doesn't get damaged if you don't catch it. Place a flat chisel along the glue joint and tap sharply with a mallet. It should pop right off. Turn a clean, slightly concave surface on the foot. After the piece is removed from the lathe, you can carve off the little nub (left in the center) with a small carving gouge and sand it smooth. PW POWER SANDING NATURAL EDGES The sanding disc is mounted in a reversible drill. The disc surface at the point of contact should be going in the opposite direction from the bowl surface at that point. Here, the disc is contacting the wood at approximately 2 o'clock; the arrows show direction of rotation. Here the disc is contacting the wood at 11 to 12 o'clock; this means the disc surface is traveling off of and away from the edge, not into it. It's very important to hold the disc in the correct position. Keep it at the level of the surface of the wings and let the sanding grit do the work. Don't push the disc toward the bowl, or it will tend to be caught as the voids come around in between the wings of the bow. At best this will round over the leading edges of the wings; at worst it could grab and damage the disc or even pull it into the gaps. It still may be necessary to do some power sanding with the lathe stopped. This tends to leave heavier scratches that are more difficult to remove, so use a soft foam disc, and pay particular attention to eliminating all marks from the previous grit before moving on to the next. —JD 90 Popular Woodworking February 2007 |