Popular Woodworking 2007-02 № 160, страница 69

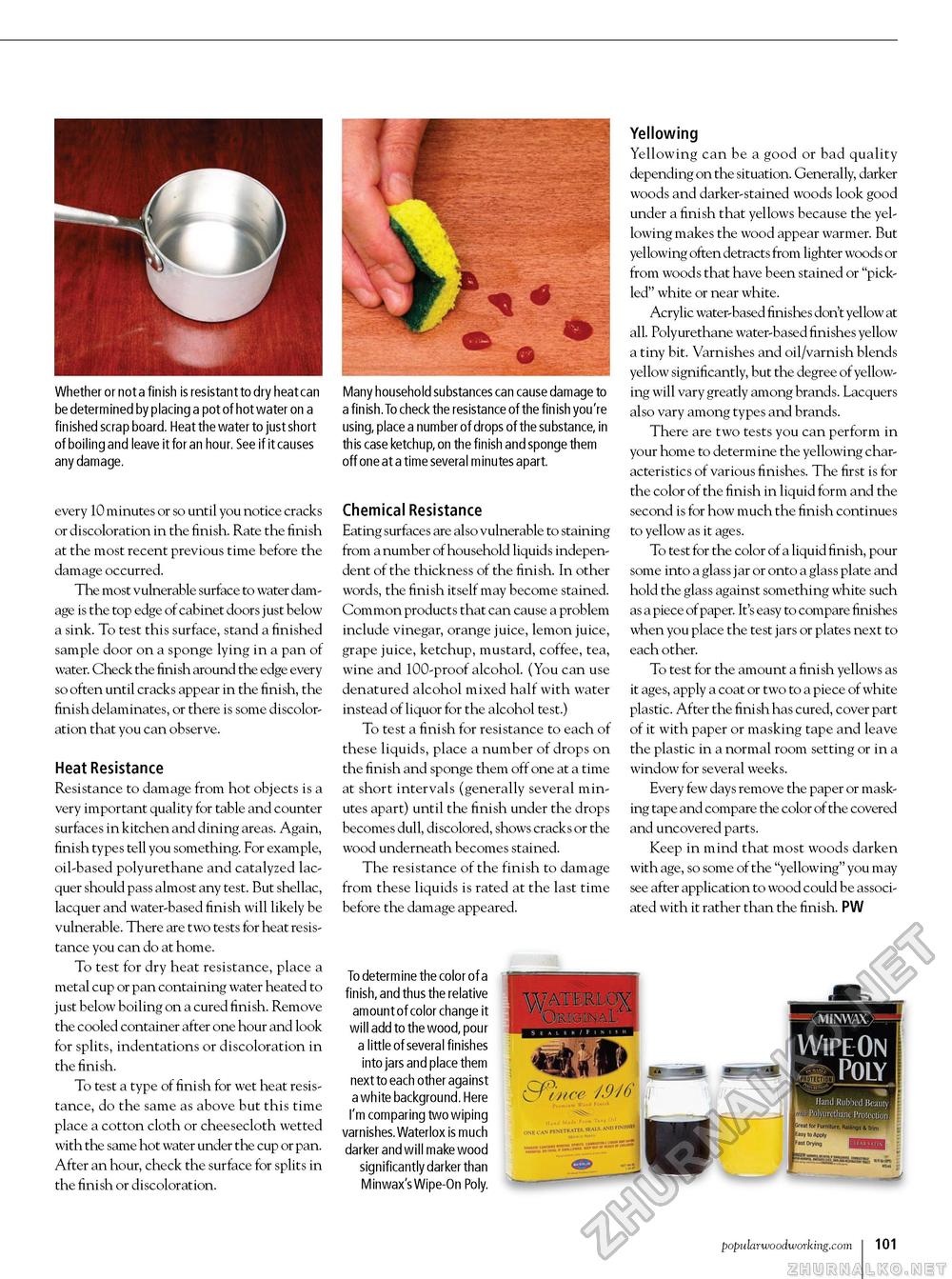

Whether or not a finish is resistant to dry heat can be determined by placing a pot of hot water on a finished scrap board. Heat the water to just short of boiling and leave it for an hour. See if it causes any damage. every 10 minutes or so until you notice cracks or discoloration in the finish. Rate the finish at the most recent previous time before the damage occurred. The most vulnerable surface to water damage is the top edge of cabinet doors just below a sink. To test this surface, stand a finished sample door on a sponge lying in a pan of water. Check the finish around the edge every so often until cracks appear in the finish, the finish delaminates, or there is some discoloration that you can observe. Heat Resistance Resistance to damage from hot objects is a very important quality for table and counter surfaces in kitchen and dining areas. Again, finish types tell you something. For example, oil-based polyurethane and catalyzed lacquer should pass almost any test. But shellac, lacquer and water-based finish will likely be vulnerable. There are two tests for heat resistance you can do at home. To test for dry heat resistance, place a metal cup or pan containing water heated to just below boiling on a cured finish. Remove the cooled container after one hour and look for splits, indentations or discoloration in the finish. To test a type of finish for wet heat resistance, do the same as above but this time place a cotton cloth or cheesecloth wetted with the same hot water under the cup or pan. After an hour, check the surface for splits in the finish or discoloration. Many household substances can cause damage to a finish. To check the resistance of the finish you're using, place a number of drops of the substance, in this case ketchup, on the finish and sponge them off one at a time several minutes apart. Chemical Resistance Eating surfaces are also vulnerable to staining from a number of household liquids independent of the thickness of the finish. In other words, the finish itself may become stained. Common products that can cause a problem include vinegar, orange juice, lemon juice, grape juice, ketchup, mustard, coffee, tea, wine and 100-proof alcohol. (You can use denatured alcohol mixed half with water instead of liquor for the alcohol test.) To test a finish for resistance to each of these liquids, place a number of drops on the finish and sponge them off one at a time at short intervals (generally several minutes apart) until the finish under the drops becomes dull, discolored, shows cracks or the wood underneath becomes stained. The resistance of the finish to damage from these liquids is rated at the last time before the damage appeared. To determine the color of a finish, and thus the relative amount of color change it will add to the wood, pour a little of several finishes into jars and place them next to each other against a white background. Here I'm comparing two wiping varnishes. Waterlox is much darker and will make wood significantly darker than Minwax's Wipe-On Poly. Yellowing Yellowing can be a good or bad quality depending on the situation. Generally, darker woods and darker-stained woods look good under a finish that yellows because the yellowing makes the wood appear warmer. But yellowing often detracts from lighter woods or from woods that have been stained or "pickled" white or near white. Acrylic water-based finishes don't yellow at all. Polyurethane water-based finishes yellow a tiny bit. Varnishes and oil/varnish blends yellow significantly, but the degree of yellowing will vary greatly among brands. Lacquers also vary among types and brands. There are two tests you can perform in your home to determine the yellowing characteristics of various finishes. The first is for the color of the finish in liquid form and the second is for how much the finish continues to yellow as it ages. To test for the color of a liquid finish, pour some into a glass jar or onto a glass plate and hold the glass against something white such as a piece of paper. It's easy to compare finishes when you place the test jars or plates next to each other. To test for the amount a finish yellows as it ages, apply a coat or two to a piece of white plastic. After the finish has cured, cover part of it with paper or masking tape and leave the plastic in a normal room setting or in a window for several weeks. Every few days remove the paper or masking tape and compare the color of the covered and uncovered parts. Keep in mind that most woods darken with age, so some of the "yellowing" you may see after application to wood could be associated with it rather than the finish. PW &%tce 19-/6' ! -(MliNVVAX>— WlPEON i f.j^Si'M'i POlAf P Hand Rubjicd Kanly SE^mibnePniicai 1 Ira at fK rwnlture, fellings & Dim *Vl0Apg* r ■Fail Diyrnj [lUj^jjAiKjj popuharwo odworking. com I 101 |