Popular Woodworking 2007-06 № 162, страница 6

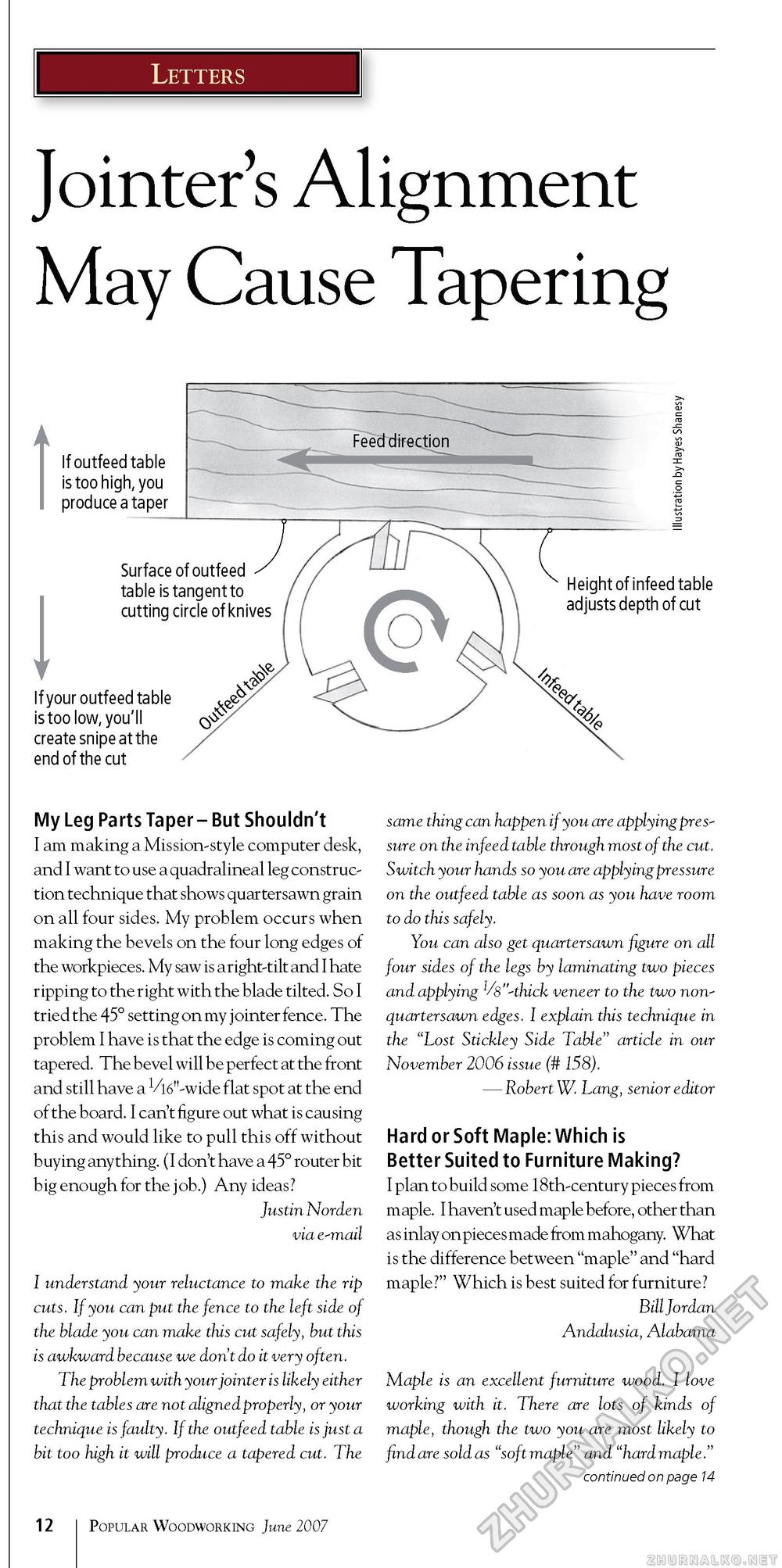

Letters Jointer's Alignment May Cause Tapering A If outfeed table is too high, you produce a taper t If your outfeed table is too low, you'll create snipe at the end of the cut Surface of outfeed table is tangent to cutting circle of knives Height of infeed table adjusts depth of cut My Leg Parts Taper - But Shouldn't I am making a Mission-style computer desk, and I want to use a quadralineal leg construction technique that shows quartersawn grain on all four sides. My problem occurs when making the bevels on the four long edges of the workpieces. My saw is a right-tilt and I hate ripping to the right with the blade tilted. So I tried the 45° setting on my jointer fence. The problem I have is that the edge is coming out tapered. The bevel will be perfect at the front and still have a V^'-wide flat spot at the end of the board. I can't figure out what is causing this and would like to pull this off without buying anything. (I don't have a 45° router bit big enough for the job.) Any ideas? Justin Norden via e-mail I understand your reluctance to make the rip cuts. If you can put the fence to the left side of the blade you can make this cut safely, but this is awkward because we don't do it very often. The problem with your jointer is likely either that the tables are not aligned properly, or your technique is faulty. If the outfeed table is just a bit too high it will produce a tapered cut. The same thing can happen if you are applying pressure on the infeed table through most of the cut. Switch your hands so you are applying pressure on the outfeed table as soon as you have room to do this safely. You can also get quartersawn figure on all four sides of the legs by laminating two pieces and applying ^s'-thick veneer to the two non-quartersawn edges. I explain this technique in the "Lost Stickley Side Table" article in our November 2006 issue (# 158). — Robert W. Lang, senior editor Hard or Soft Maple: Which is Better Suited to Furniture Making? I plan to build some 18th-century pieces from maple. I haven't used maple before, other than as inlay on pieces made from mahogany. What is the difference between "maple" and "hard maple?" Which is best suited for furniture? Bill Jordan Andalusia, Alabama Maple is an excellent furniture wood. I love working with it. There are lots of kinds of maple, though the two you are most likely to find are sold as "soft maple" and "hard maple." continued on page 14 12 Popular Woodworking June 2007 |