Popular Woodworking 2007-08 № 163, страница 33

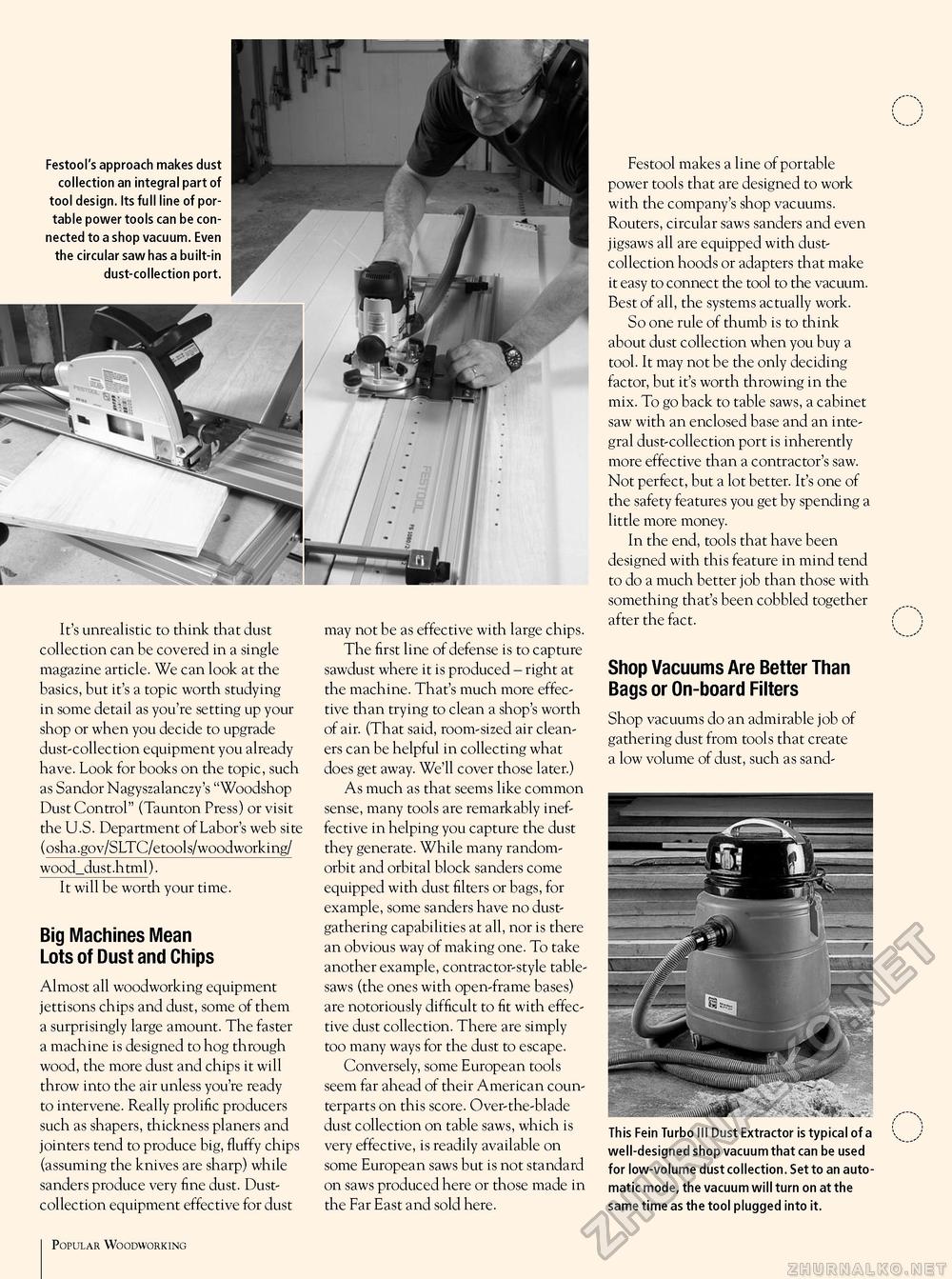

It's unrealistic to think that dust collection can be covered in a single magazine article. We can look at the basics, but it's a topic worth studying in some detail as you're setting up your shop or when you decide to upgrade dust-collection equipment you already have. Look for books on the topic, such as Sandor Nagyszalanczy's "Woodshop Dust Control" (Taunton Press) or visit the U.S. Department of Labor's web site (osha.gov/SLTC/etools/woodworking/ wood_dust.html). It will be worth your time. Big Machines Mean Lots of Dust and Chips Almost all woodworking equipment jettisons chips and dust, some of them a surprisingly large amount. The faster a machine is designed to hog through wood, the more dust and chips it will throw into the air unless you're ready to intervene. Really prolific producers such as shapers, thickness planers and jointers tend to produce big, fluffy chips (assuming the knives are sharp) while sanders produce very fine dust. Dust-collection equipment effective for dust may not be as effective with large chips. The first line of defense is to capture sawdust where it is produced - right at the machine. That's much more effective than trying to clean a shop's worth of air. (That said, room-sized air cleaners can be helpful in collecting what does get away. We'll cover those later.) As much as that seems like common sense, many tools are remarkably ineffective in helping you capture the dust they generate. While many random-orbit and orbital block sanders come equipped with dust filters or bags, for example, some sanders have no dust-gathering capabilities at all, nor is there an obvious way of making one. To take another example, contractor-style table-saws (the ones with open-frame bases) are notoriously difficult to fit with effective dust collection. There are simply too many ways for the dust to escape. Conversely, some European tools seem far ahead of their American counterparts on this score. Over-the-blade dust collection on table saws, which is very effective, is readily available on some European saws but is not standard on saws produced here or those made in the Far East and sold here. Festool makes a line of portable power tools that are designed to work with the company's shop vacuums. Routers, circular saws sanders and even jigsaws all are equipped with dust-collection hoods or adapters that make it easy to connect the tool to the vacuum. Best of all, the systems actually work. So one rule of thumb is to think about dust collection when you buy a tool. It may not be the only deciding factor, but it's worth throwing in the mix. To go back to table saws, a cabinet saw with an enclosed base and an integral dust-collection port is inherently more effective than a contractor's saw. Not perfect, but a lot better. It's one of the safety features you get by spending a little more money. In the end, tools that have been designed with this feature in mind tend to do a much better job than those with something that's been cobbled together after the fact. Shop Vacuums Are Better Than Bags or On-board Filters Shop vacuums do an admirable job of gathering dust from tools that create a low volume of dust, such as sand- This Fein Turbo III Dust Extractor is typical of a well-designed shop vacuum that can be used for low-volume dust collection. Set to an automatic mode, the vacuum will turn on at the same time as the tool plugged into it. Popular Woodworking |