Popular Woodworking 2007-08 № 163, страница 51

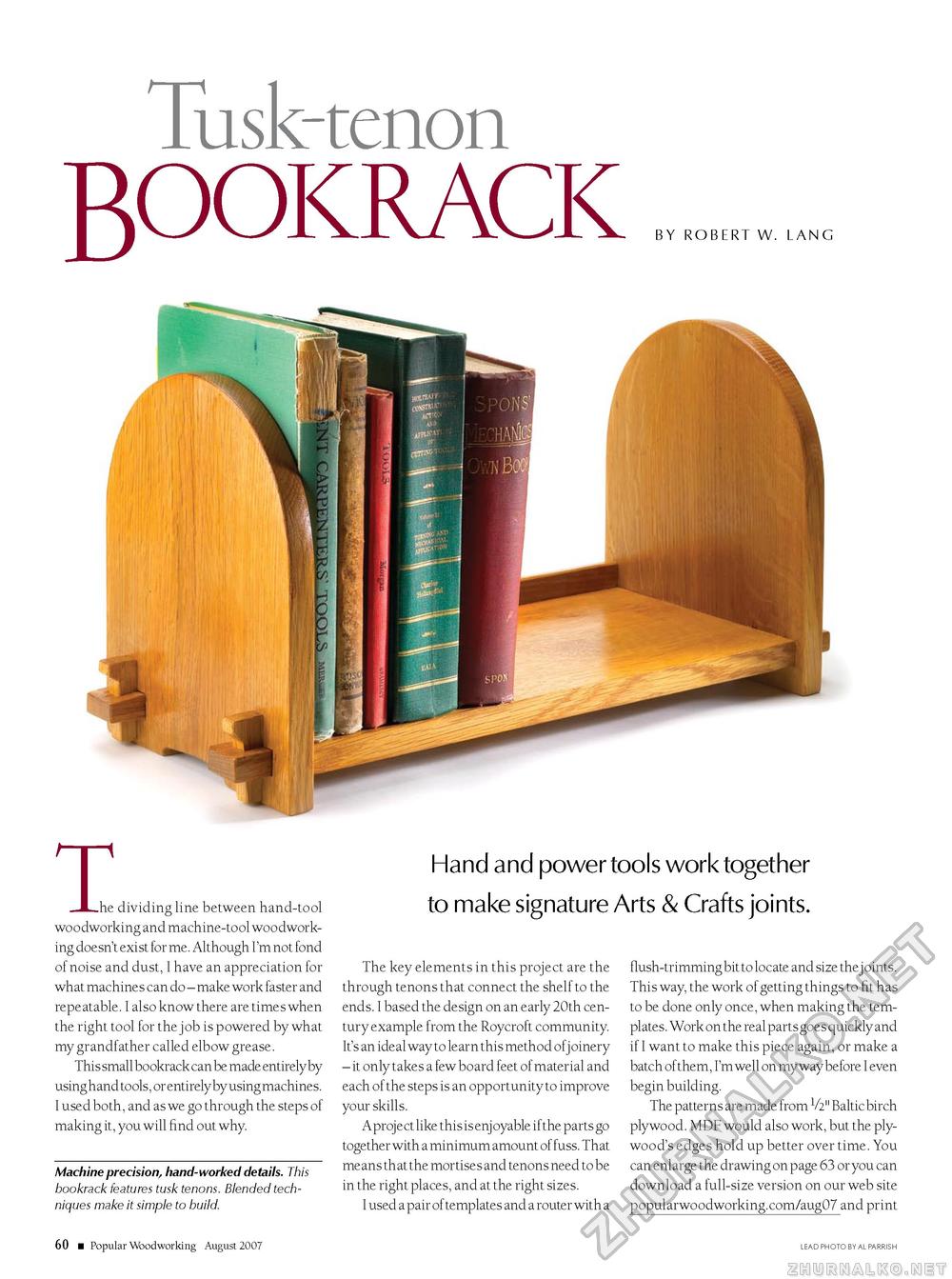

Tusk-tenon OOK R ACK by robert w. lang T he he dividing line between hand-tool woodworking and machine-tool woodworking doesn't exist for me. Although I'm not fond of noise and dust, I have an appreciation for what machines can do - make work faster and repeatable. I also know there are times when the right tool for the job is powered by what my grandfather called elbow grease. This small bookrack can be made entirely by using hand tools, or entirely by using machines. I used both, and as we go through the steps of making it, you will find out why. Machine precision, hand-worked details. This bookrack features tusk tenons. Blended techniques make it simple to build. Hand and power tools work together to make signature Arts & Crafts joints. The key elements in this project are the through tenons that connect the shelf to the ends. I based the design on an early 20th century example from the Roycroft community. It's an ideal way to learn this method ofj oinery - it only takes a few board feet of material and each of the steps is an opportunity to improve your skills. A project like this is enjoyable ifthe parts go together with a minimum amount of fuss. That means that the mortises and tenons need to be in the right places, and at the right sizes. I used a pair of templates and a router with a flush-trimming bit to locate and size the j oints. This way, the work of getting things to fit has to be done only once, when making the templates. Work on the real parts goes quickly and if I want to make this piece again, or make a batch of them, I'm well on my way before I even begin building. The patterns are made from V2" Baltic birch plywood. MDF would also work, but the plywood's edges hold up better over time. You can enlarge the drawing on page 63 or you can download a full-size version on our web site popularwoodworking.com/aug07 and print 60 ■ Popular Woodworking August 2007 lead photo by al parrish |