Popular Woodworking 2007-08 № 163, страница 56

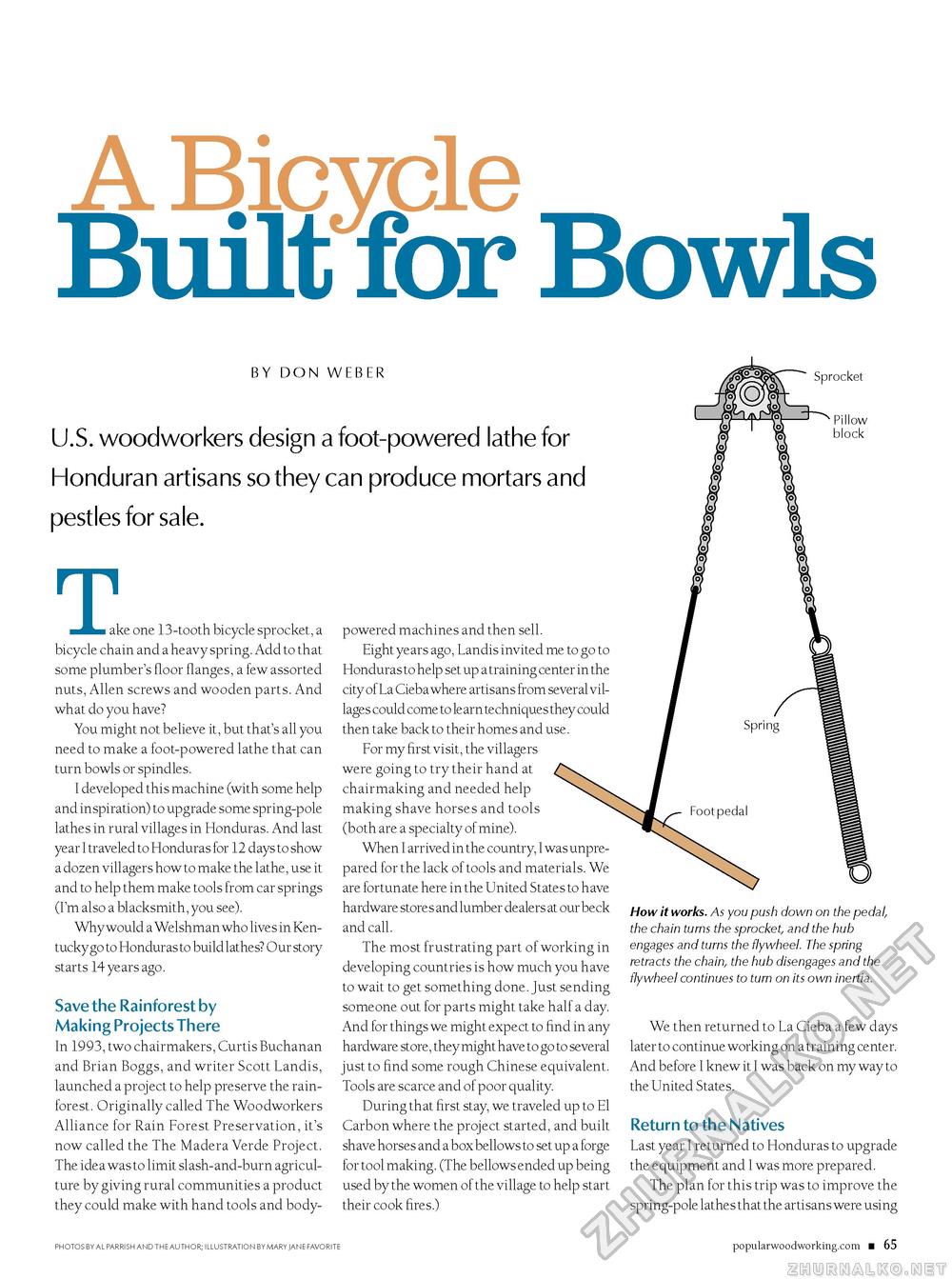

A BicycleBuilt for BowlsBY DON WEBER U.s. woodworkers design a foot-powered lathe for Honduran artisans so they can produce mortars and pestles for sale. sprocket Pillow block T ake one 13-tooth bicycle sprocket, a bicycle chain and a heavy spring. Add to that some plumber's floor flanges, a few assorted nuts, Allen screws and wooden parts. And what do you have? You might not believe it, but that's all you need to make a foot-powered lathe that can turn bowls or spindles. I developed this machine (with some help and inspiration) to upgrade some spring-pole lathes in rural villages in Honduras. And last year I traveled to Honduras for 12 days to show a dozen villagers how to make the lathe, use it and to help them make tools from car springs (I'm also a blacksmith, you see). Why would a Welshman who lives in Kentucky go to Honduras to build lathes? Our story starts 14 years ago. Save the Rainforest by Making Projects There In 1993, two chairmakers, Curtis Buchanan and Brian Boggs, and writer Scott Landis, launched a project to help preserve the rainforest. Originally called The Woodworkers Alliance for Rain Forest Preservation, it's now called the The Madera Verde Project. The idea was to limit slash-and-burn agriculture by giving rural communities a product they could make with hand tools and body- powered machines and then sell. Eight years ago, Landis invited me to go to Honduras to help set up a training center in the city of La Cieba where artisans from several villages could come to le arn techniques they could then take back to their homes and use. For my first visit, the villagers were going to try their hand at chairmaking and needed help making shave horses and tools (both are a specialty of mine). When I arrived in the country, I was unprepared for the lack of tools and materials. We are fortunate here in the United States to have hardware stores and lumber dealers at our beck and call. The most frustrating part of working in developing countries is how much you have to wait to get something done. Just sending someone out for parts might take half a day. And for things we might expect to find in any hardware store, they might have to go to several just to find some rough Chinese equivalent. Tools are scarce and of poor quality. During that first stay, we traveled up to El Carbon where the project started, and built shave horses and a box bellows to set up a forge for tool making. (The bellows ended up being used by the women of the village to help start their cook fires.) How it works. As you push down on the pedal, the chain turns the sprocket, and the hub engages and turns the flywheel. The spring retracts the chain, the hub disengages and the flywheel continues to turn on its own inertia. We then returned to La Cieba a few days later to continue working on a training center. And before I knew it I was back on my way to the United States. Return to the Natives Last year I returned to Honduras to upgrade the equipment and I was more prepared. The plan for this trip was to improve the spring-pole lathes that the artisans were using PHOTOs BY AL PARRisH AND THE AUTHOR; ILLUsTRATION BY MARY JANE FAVORITE popularwoodworking.com ■ 65 |