Popular Woodworking 2007-10 № 164, страница 75

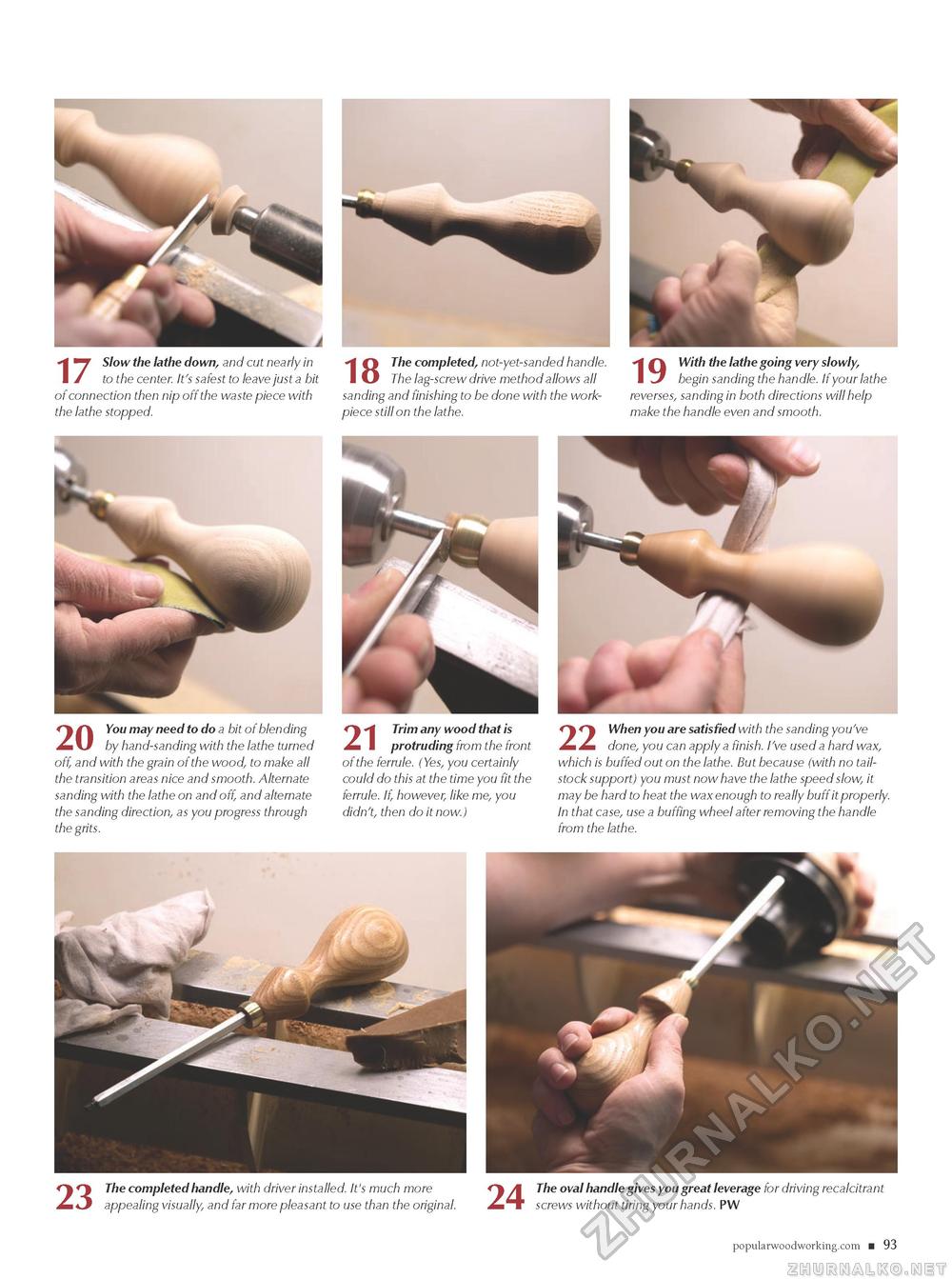

^ Slow the lathe down, and cut nearly in I J to the center. It's safest to leave just a bit of connection then nip off the waste piece with the lathe stopped. O The completed, not-yet-sanded handle. I \J The lag-screw drive method allows all sanding and finishing to be done with the work-piece still on the lathe. "fl O With the lathe going very slowly, I 3/ begin sanding the handle. If your lathe reverses, sanding in both directions will help make the handle even and smooth. /"fc You may need to do a bit of blen ding ^ vr by hand-sanding with the lathe turned off, and with the grain of the wood, to make all the transition areas nice and smooth. Alternate sanding with the lathe on and off, and alternate the sanding direction, as you progress through the grits. Trim any wood that is ^ I protruding from the front of the ferrule. (Yes, you certainly could do this at the time you fit the ferrule. If, however, like me, you didn't, then do it now.) 22 When you are satisfied with the sanding you've done, you can apply a finish. I've used a hard wax, which is buffed out on the lathe. But because (with no tail-stock support) you must now have the lathe speed slow, it may be hard to heat the wax enough to really buff it properly. In that case, use a buffing wheel after removing the handle from the lathe. <y The completed handle, with driver installed. It's much more ^ <J appealing visually, and far more pleasant to use than the original. The oval handle gives you great leverage for driving recalcitrant screws without tiring your hands. PW popularwoodworking.com ■ 93 CIRCLE #152 ON FREE INFORMATION CARD. |