Popular Woodworking 2007-11 № 165, страница 29

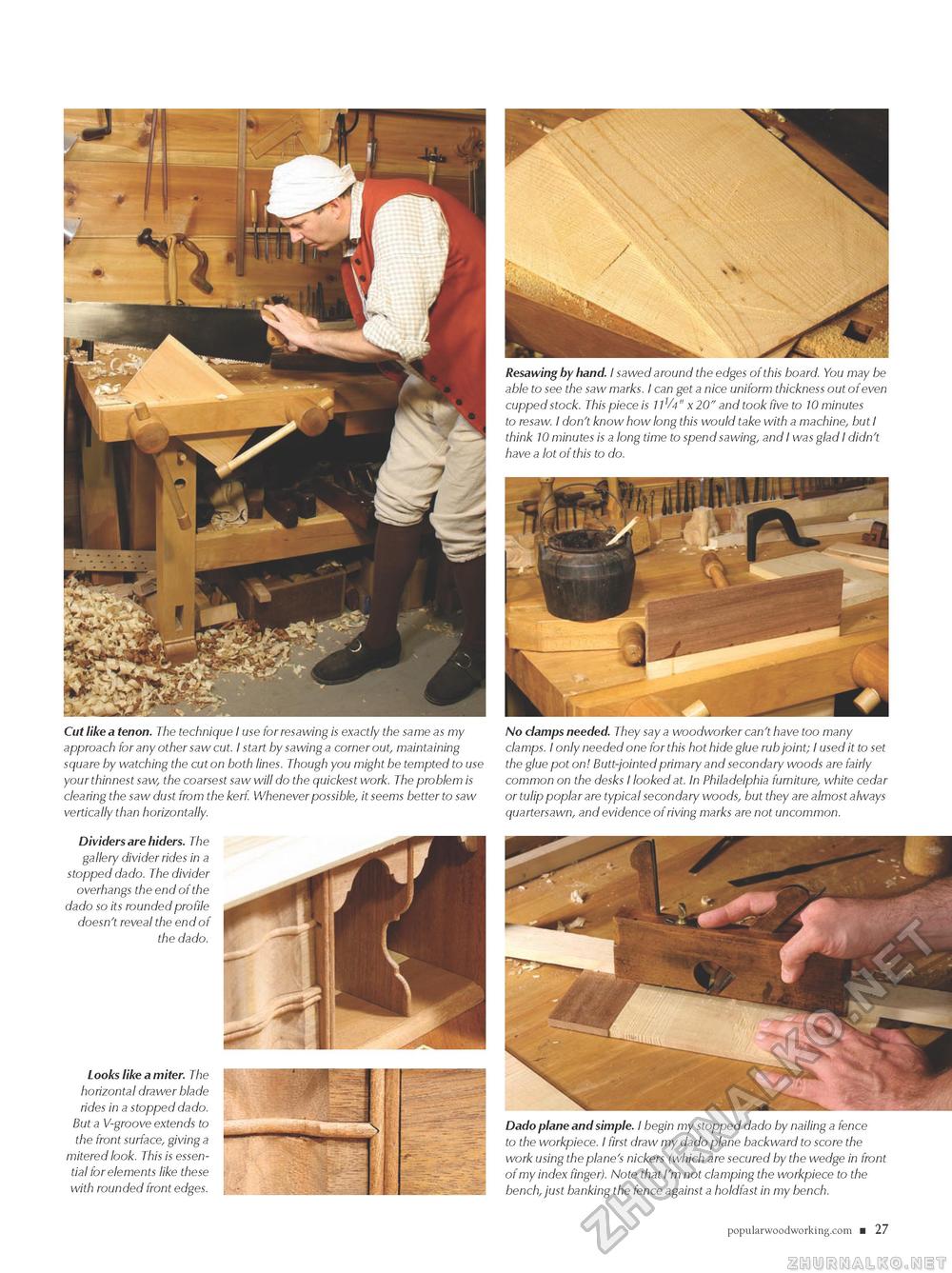

Resawing by hand. I sawed around the edges of this board. You may be able to see the saw marks. I can get a nice uniform thickness out of even cupped stock. This piece is 111/4" x 20" and took five to 10 minutes to resaw. I don't know how long this would take with a machine, but I think 10 minutes is a long time to spend sawing, and I was glad I didn't have a lot of this to do. Cut like a tenon. The technique I use for resawing is exactly the same as my approach for any other saw cut. I start by sawing a corner out, maintaining square by watching the cut on both lines. Though you might be tempted to use your thinnest saw, the coarsest saw will do the quickest work. The problem is clearing the saw dust from the kerf. Whenever possible, it seems better to saw vertically than horizontally. Dividers are hiders. The gallery divider rides in a stopped dado. The divider overhangs the end of the dado so its rounded profile doesn't reveal the end of the dado. No clamps needed. They say a woodworker can't have too many clamps. I only needed one for this hot hide glue rub joint; I used it to set the glue pot on! Butt-jointed primary and secondary woods are fairly common on the desks I looked at. In Philadelphia furniture, white cedar or tulip poplar are typical secondary woods, but they are almost always quartersawn, and evidence of riving marks are not uncommon. Looks like a miter. The horizontal drawer blade rides in a stopped dado. But a V-groove extends to the front surface, giving a mitered look. This is essential for elements like these with rounded front edges. Dado plane and simple. I begin my stopped dado by nailing a fence to the workpiece. I first draw my dado plane backward to score the work using the plane's nickers (which are secured by the wedge in front of my index finger). Note that I'm not clamping the workpiece to the bench, just banking the fence against a holdfast in my bench. popularwoodworking.com ■ 27 |