Popular Woodworking 2007-11 № 165, страница 80

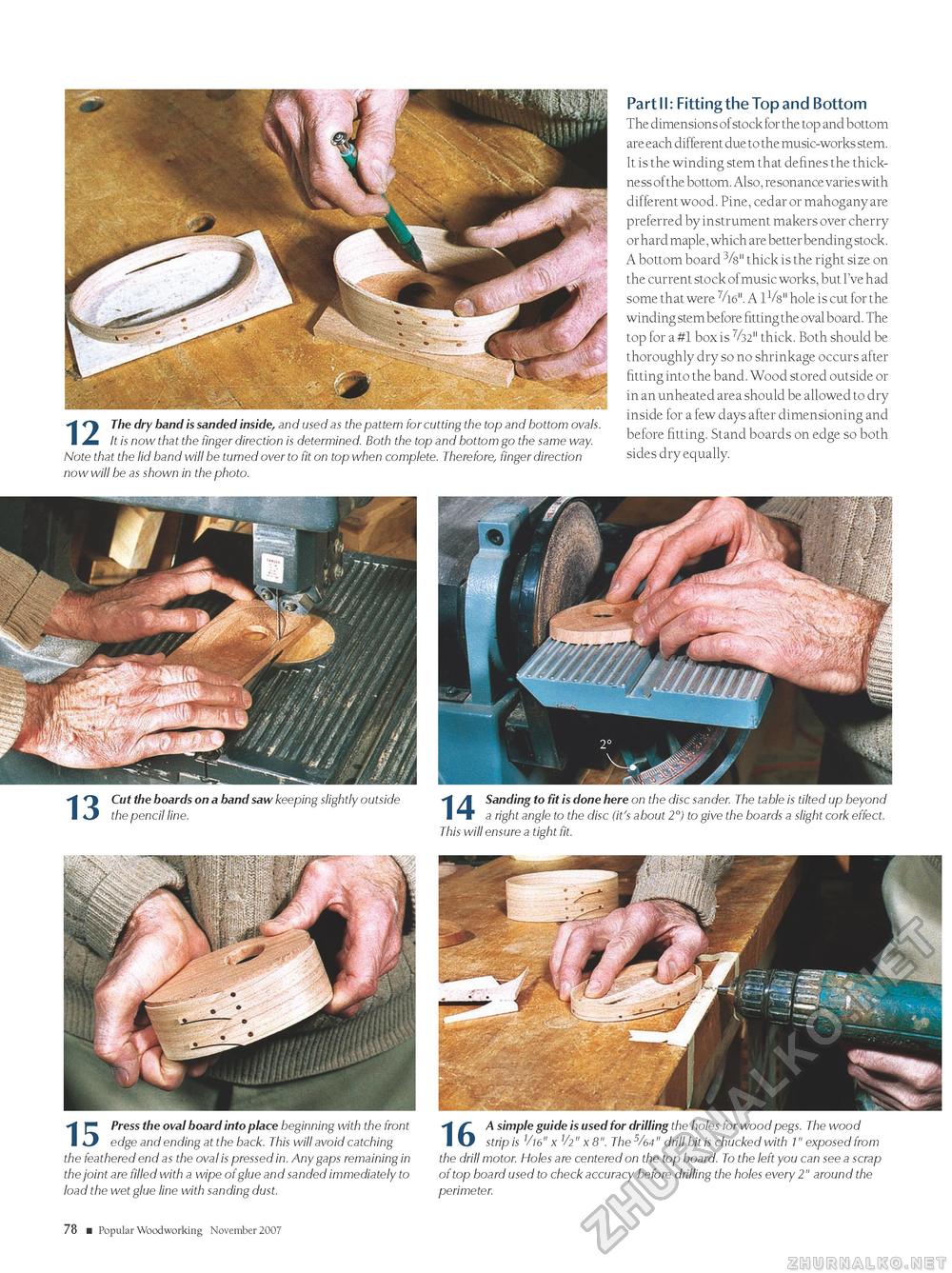

The dry band is sanded inside, and used as the pattern for cutting the top and bottom ovals. I ^ It is now that the finger direction is determined. Both the top and bottom go the same way. Note that the lid band will be turned over to fit on top when complete. Therefore, finger direction now will be as shown in the photo. Part 11: Fitting the Top and Bottom The dimensions ofstock for the top and bottom are each different due to the music-works stem. It is the winding stem that defines the thickness of the bottom. Also, resonance varies with different wood. Pine, cedar or mahogany are preferred by instrument makers over cherry or hard maple, which are better bending stock. A bottom board 3/s" thick is the right size on the current stock of music works, but I've had some that were 7/l6". A lVs" hole is cut for the winding stem before fitting the oval board. The top for a #1 box is 7/32" thick. Both should be thoroughly dry so no shrinkage occurs after fitting into the band. Wood stored outside or in an unheated area should be allowed to dry inside for a few days after dimensioning and before fitting. Stand boards on edge so both sides dry equally. "t <3 Cut the boards on a band saw keeping slightly outside *t /I Sanding to fit is done here on the disc sander. The table is tilted up beyond I <J the pencil line. I ^w a right angle to the disc (it's about 2°) to give the boards a slight cork effect. This will ensure a tight fit. Press the oval board into place beginning with the front edge and ending at the back. This will avoid catching the feathered end as the oval is pressed in. Any gaps remaining in the joint are filled with a wipe of glue and sanded immediately to load the wet glue line with sanding dust. £~ A simple guide is used for drilling the holes for wood pegs. The wood I Vj strip is Vie" x Vi" x 8". The Ve4" drill bit is chucked with I" exposed from the drill motor. Holes are centered on the top board. To the left you can see a scrap of top board used to check accuracy before drilling the holes every 2" around the perimeter. 78 ■ Popular Woodworking November 2007 |