Popular Woodworking 2007-11 № 165, страница 77

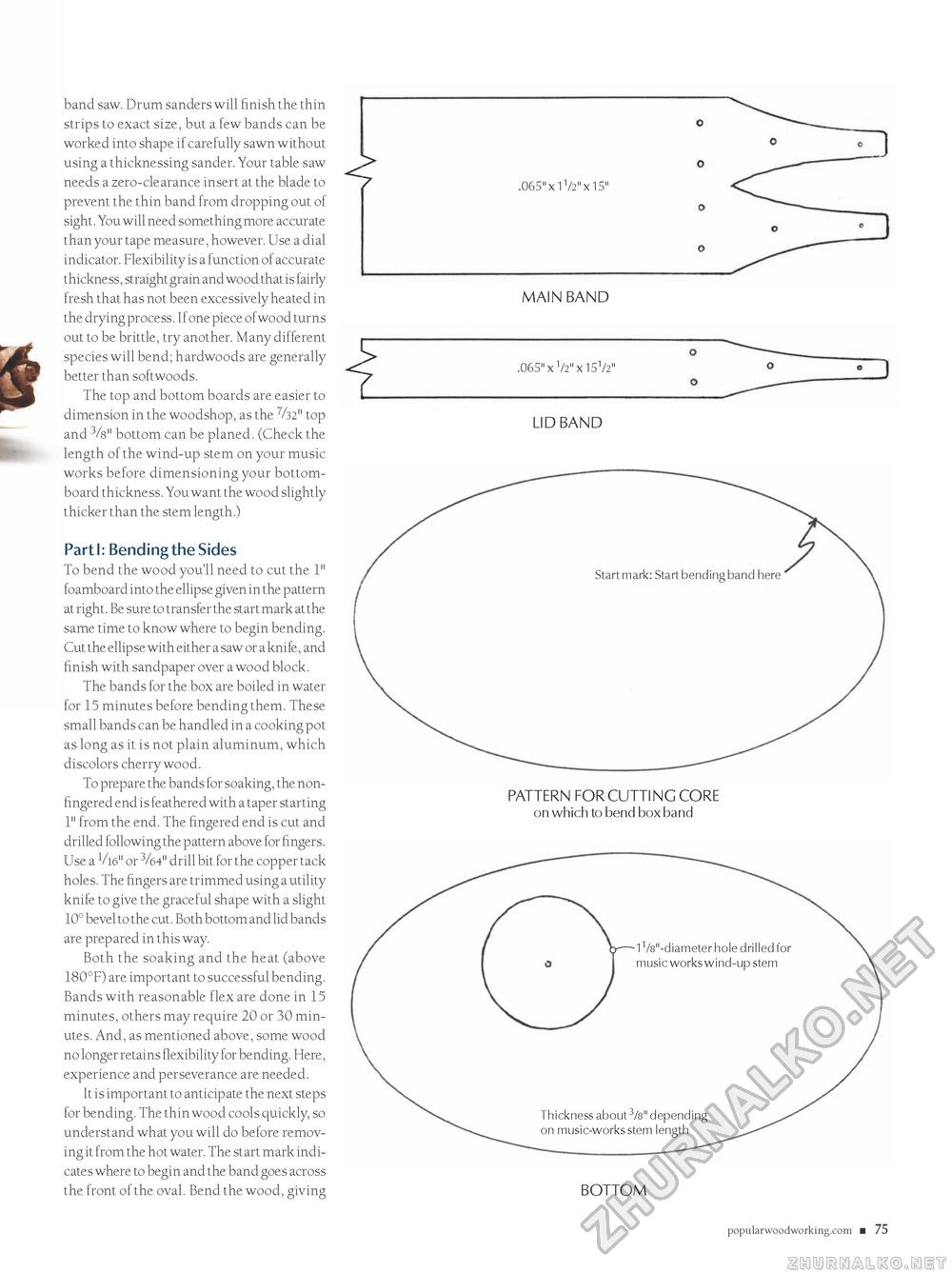

band saw. Drum sanders will finish the thin strips to exact size, but a few bands can be worked into shape if carefully sawn without using a thicknessing sander. Your table saw needs a zero-clearance insert at the blade to prevent the thin band from dropping out of sight. You will need something more accurate than your tape measure, however. Use a dial indicator. Flexibility is a function of accurate thickness, straight grain and wood that is fairly fresh that has not been excessively heated in the drying process. If one piece ofwood turns out to be brittle, try another. Many different species will bend; hardwoods are generally better than softwoods. The top and bottom boards are easier to dimension in the woodshop, as the 7/32" top and 3/8" bottom can be planed. (Check the length of the wind-up stem on your music works before dimensioning your bottom-board thickness. You want the wood slightly thicker than the stem length.) Part I: Bending the Sides To bend the wood you'll need to cut the 1" foamboard into the ellipse given in the pattern at right. Be sure to transfer the start mark at the same time to know where to begin bending. Cut the ellipse with either a saw or a knife, and finish with sandpaper over a wood block. The bands for the box are boiled in water for 15 minutes before bending them. These small bands can be handled in a cooking pot as long as it is not plain aluminum, which discolors cherry wood. To prepare the bands for soaking, the non-fingered end is feathered with a taper starting 1" from the end. The fingered end is cut and drilled following the pattern above for fingers. Use a or 3/64" drill bit for the copper tack holes. The fingers are trimmed using a utility knife to give the graceful shape with a slight 10° bevel to the cut. Both bottom and lid bands are prepared in this way. Both the soaking and the heat (above 180°F) are important to successful bending. Bands with reasonable flex are done in 15 minutes, others may require 20 or 30 minutes. And, as mentioned above, some wood no longer retains flexibility for bending. Here, experience and perseverance are needed. It is important to anticipate the next steps for bending. The thin wood cools quickly, so understand what you will do before removing it from the hot water. The start mark indicates where to begin and the band goes across the front of the oval. Bend the wood, giving PATTERN FOR CUTTING CORE on which to bend box band BOTTOM popularwoodworking.com ■ 75 |