Popular Woodworking 2007-12 № 166, страница 52

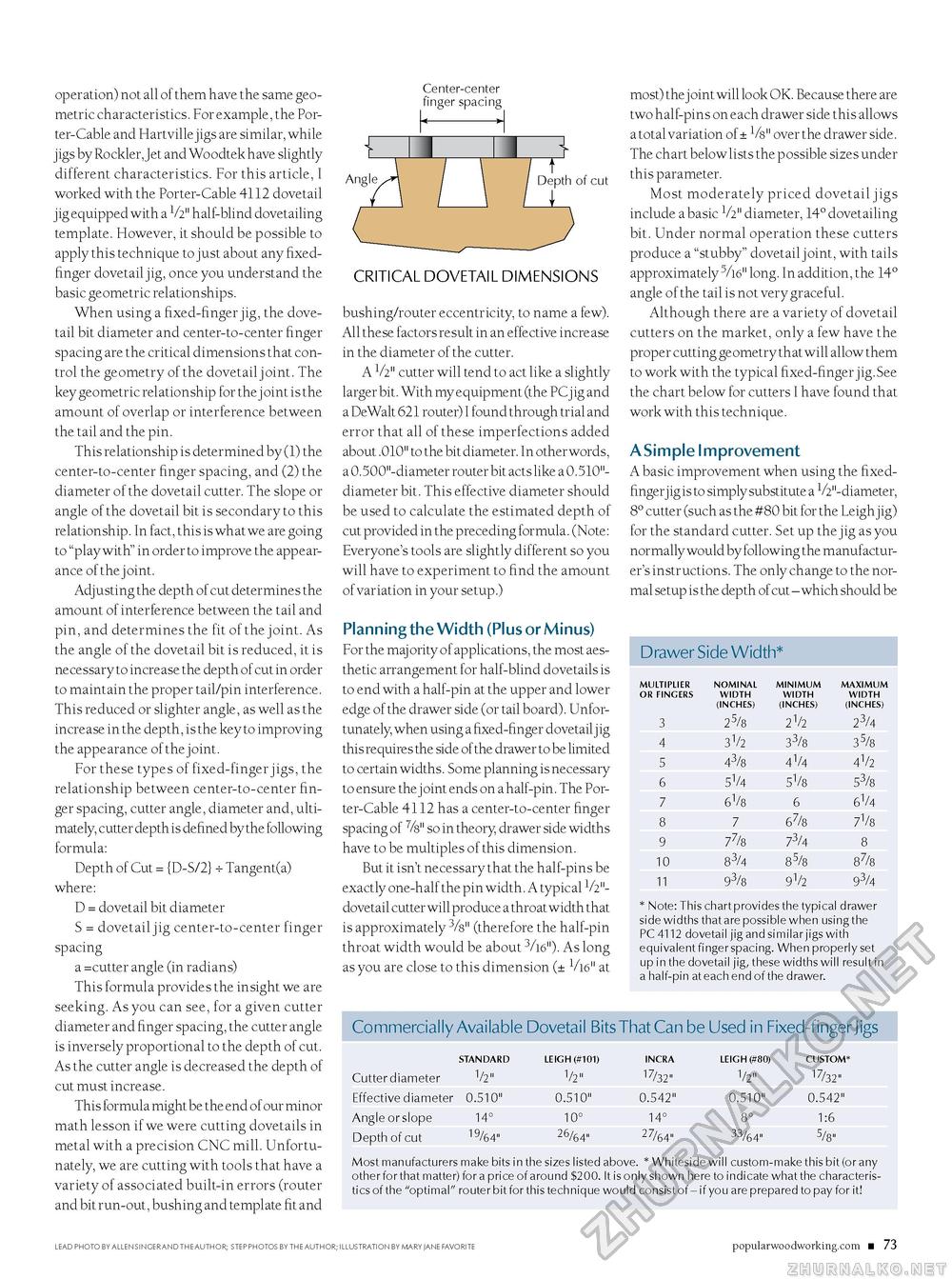

operation) not all of them have the same geometric characteristics. For example, the Porter-Cable and Hartville jigs are similar, while jigs by Rockler, Jet and Woodtek have slightly different characteristics. For this article, I worked with the Porter-Cable 4112 dovetail jig equipped with a V2" half-blind dovetailing template. However, it should be possible to apply this technique to just about any fixed-finger dovetail jig, once you understand the basic geometric relationships. When using a fixed-finger jig, the dovetail bit diameter and center-to-center finger spacing are the critical dimensions that control the geometry of the dovetail joint. The key geometric relationship for the j oint is the amount of overlap or interference between the tail and the pin. This relationship is determined by (1) the center-to-center finger spacing, and (2) the diameter of the dovetail cutter. The slope or angle of the dovetail bit is secondary to this relationship. In fact, this is what we are going to "play with" in order to improve the appearance of the joint. Adjusting the depth of cut determines the amount of interference between the tail and pin, and determines the fit of the joint. As the angle of the dovetail bit is reduced, it is necessary to increase the depth of cut in order to maintain the proper tail/pin interference. This reduced or slighter angle, as well as the increase in the depth, is the key to improving the appearance of the joint. For these types of fixed-finger jigs, the relationship between center-to-center finger spacing, cutter angle, diameter and, ultimately, cutter depth is defined by the following formula: Depth of Cut = {D-S/2} - Tangent(a) where: D = dovetail bit diameter S = dovetail jig center-to-center finger spacing a =cutter angle (in radians) This formula provides the insight we are seeking. As you can see, for a given cutter diameter and finger spacing, the cutter angle is inversely proportional to the depth of cut. As the cutter angle is decreased the depth of cut must increase. This formula might be the end of our minor math lesson if we were cutting dovetails in metal with a precision CNC mill. Unfortunately, we are cutting with tools that have a variety of associated built-in errors (router and bit run-out, bushing and template fit and Center-center finger spacing bushing/router eccentricity, to name a few). All these factors result in an effective increase in the diameter of the cutter. A V2" cutter will tend to act like a slightly larger bit. With my equipment (the PCjig and a DeWalt 621 router) I found through trial and error that all of these imperfections added about .010" to the bit diameter. In other words, a 0.500" '-diameter router bit acts like a 0.510"-diameter bit. This effective diameter should be used to calculate the estimated depth of cut provided in the preceding formula. (Note: Everyone's tools are slightly different so you will have to experiment to find the amount of variation in your setup.) Planning the Width (Plus or Minus) For the maj ority of applications, the most aesthetic arrangement for half-blind dovetails is to end with a half-pin at the upper and lower edge of the drawer side (or tail board). Unfortunately, when using a fixed-finger dovetail j ig this requires the side of the drawer to be limited to certain widths. Some planning is necessary to ensure the joint ends on a half-pin. The Porter-Cable 4112 has a center-to-center finger spacing of %" so in theory, drawer side widths have to be multiples of this dimension. But it isn't necessary that the half-pins be exactly one-half the pin width. A typical V2"-dovetail cutter will produce a throat width that is approximately 3/8" (therefore the half-pin throat width would be about 3/t6"). As long as you are close to this dimension (± V16" at most) the joint will look OK. Because there are two half-pins on each drawer side this allows a total variation of ± V8" over the drawer side. The chart below lists the possible sizes under this parameter. Most moderately priced dovetail jigs include a basic V2" diameter, 14° dovetailing bit. Under normal operation these cutters produce a "stubby" dovetail joint, with tails approximately 5/t6" long. In addition, the 14° angle of the tail is not very graceful. Although there are a variety of dovetail cutters on the market, only a few have the proper cutting geometry that will allow them to work with the typical fixed-finger jig.See the chart below for cutters I have found that work with this technique. A Simple Improvement A basic improvement when using the fixed-finger j ig is to simply substitute a 1/2"-diameter, 8° cutter (such as the #80 bit for the Leigh jig) for the standard cutter. Set up the jig as you normally would by following the manufacturer's instructions. The only change to the normal setup is the depth of cut - which should be Drawer Side Width*

* Note: This chart provides the typical drawer side widths that are possible when using the PC 4112 dovetail jig and similar jigs with equivalent finger spacing. When properly set up in the dovetail jig, these widths will result in a half-pin at each end of the drawer. * Note: This chart provides the typical drawer side widths that are possible when using the PC 4112 dovetail jig and similar jigs with equivalent finger spacing. When properly set up in the dovetail jig, these widths will result in a half-pin at each end of the drawer. Commercially Available Dovetail Bits That Can be Used in Fixed-finger Jigs STANDARD LEIGH (#101) INCRA LEIGH (#80) CUSTOM* Cutter diameter V2" V2" 17/32" V2" 17/32" STANDARD LEIGH (#101) INCRA LEIGH (#80) CUSTOM* Cutter diameter V2" V2" 17/32" V2" 17/32"

Most manufacturers make bits in the sizes listed above. * Whiteside will custom-make this bit (or any other for that matter) for a price of around $200. it is only shown here to indicate what the characteristics of the "optimal" router bit for this technique would consist of - if you are prepared to pay for it! Most manufacturers make bits in the sizes listed above. * Whiteside will custom-make this bit (or any other for that matter) for a price of around $200. it is only shown here to indicate what the characteristics of the "optimal" router bit for this technique would consist of - if you are prepared to pay for it! LEAD PHOTO BY ALLEN SINGER AND THE AUTHOR; STEP PHOTOS BY THE AUTHOR; ILLUSTRATION BY MARY JANE FAVORITE popularwoodworking.com ■ 73 |