Popular Woodworking 2008-04 № 168, страница 60

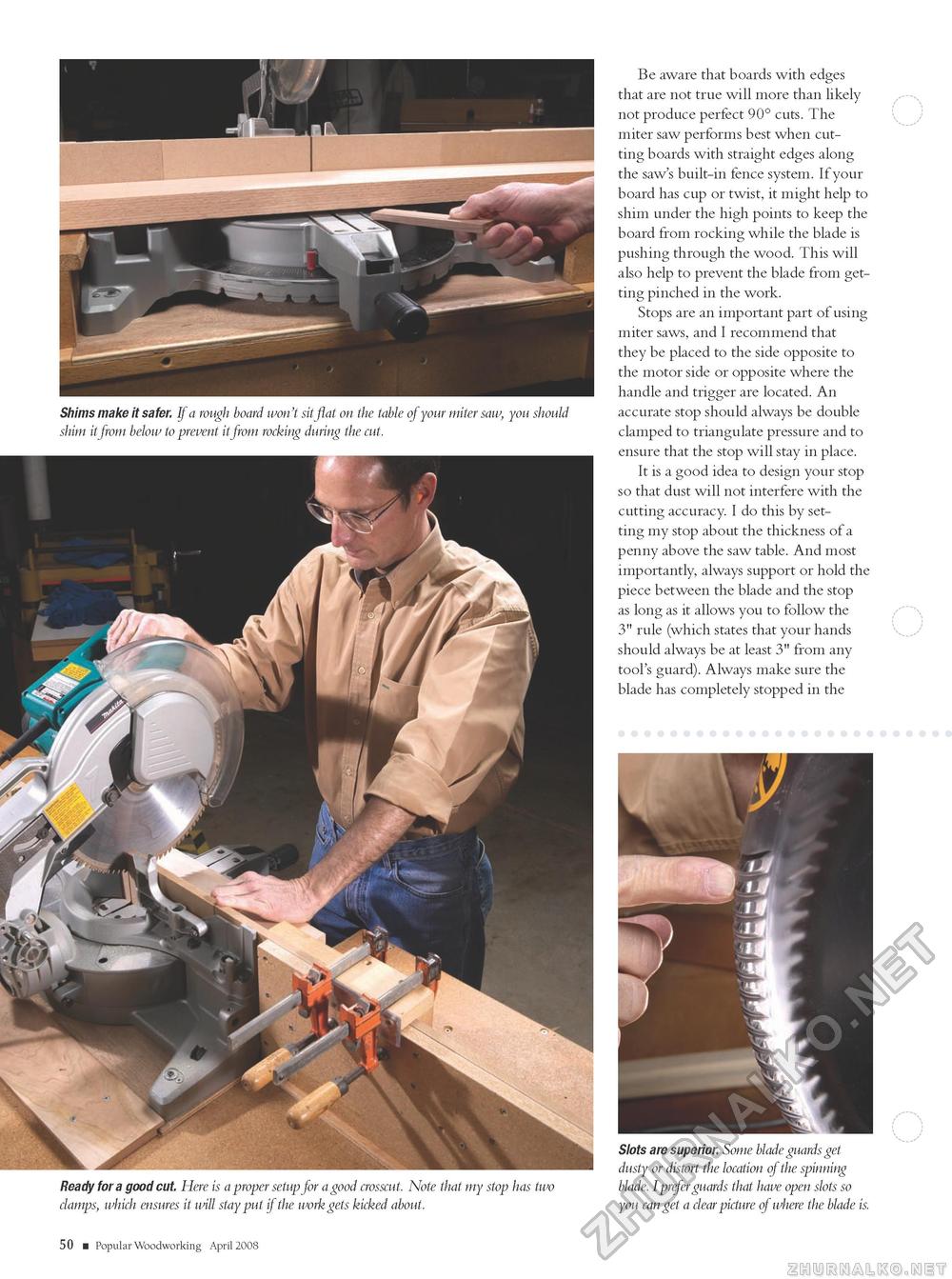

Shims make it safer. f a rough board won't sit flat on the table of your miter saw, you should shim it from below to prevent it from rocking during the cut. Ready for a good cut. Here is a proper setup for a good crosscut. Note that my stop has two clamps, which ensures it will stay put if the work gets kicked about. Be aware that boards with edges that are not true will more than likely not produce perfect 90° cuts. The miter saw performs best when cutting boards with straight edges along the saw's built-in fence system. If your board has cup or twist, it might help to shim under the high points to keep the board from rocking while the blade is pushing through the wood. This will also help to prevent the blade from getting pinched in the work. Stops are an important part of using miter saws, and I recommend that they be placed to the side opposite to the motor side or opposite where the handle and trigger are located. An accurate stop should always be double clamped to triangulate pressure and to ensure that the stop will stay in place. It is a good idea to design your stop so that dust will not interfere with the cutting accuracy. I do this by setting my stop about the thickness of a penny above the saw table. And most importantly, always support or hold the piece between the blade and the stop as long as it allows you to follow the 3" rule (which states that your hands should always be at least 3" from any tool's guard). Always make sure the blade has completely stopped in the Slots are superior. Some blade guards get dusty or distort the location of the spinning blade. I prefer guards that have open slots so you can get a clear picture of where the blade is. 50 ■ Popular Woodworking April 2008 MX |