Popular Woodworking 2008-04 № 168, страница 59

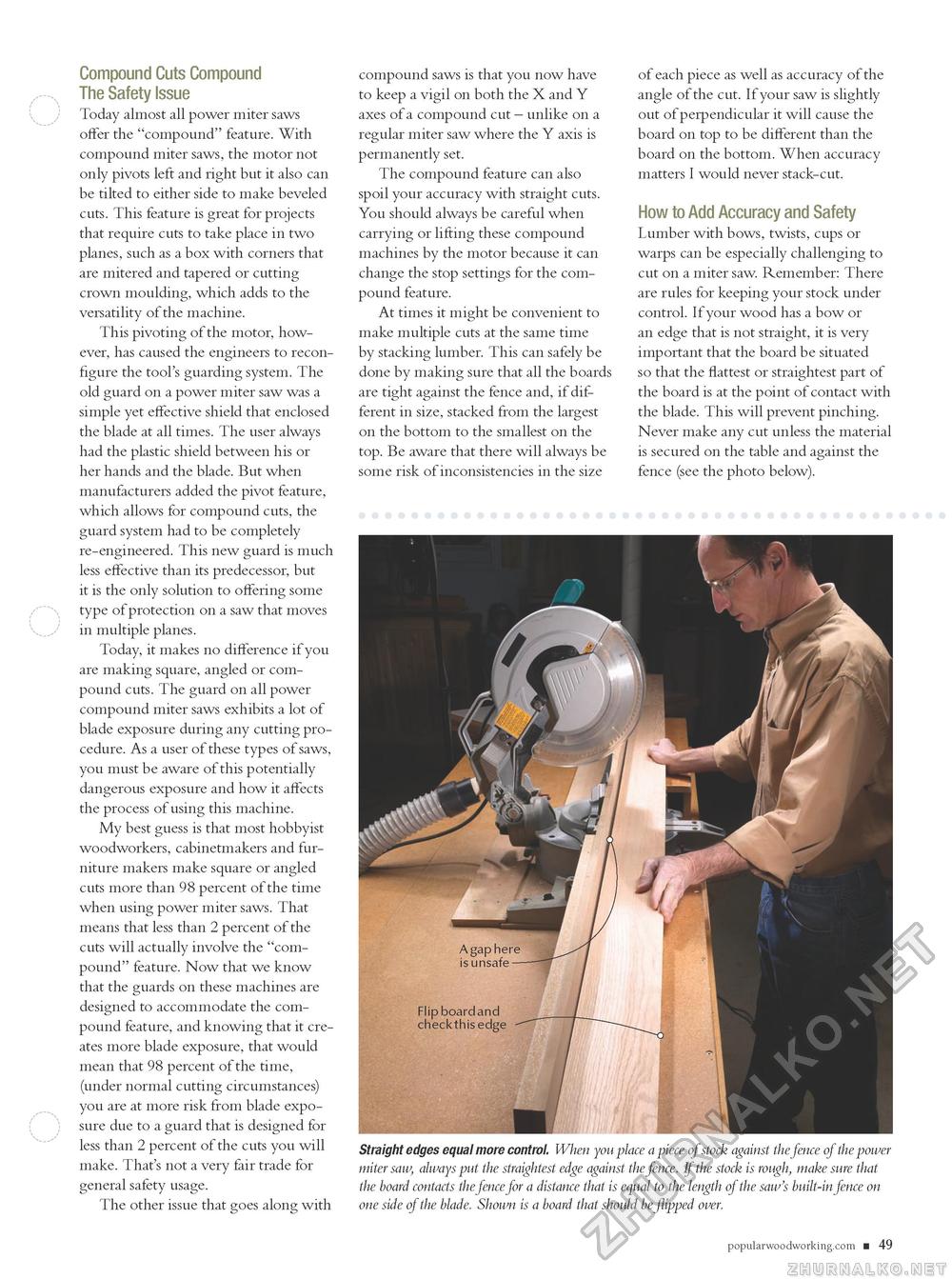

Compound Cuts Compound The Safety Issue Today almost all power miter saws offer the "compound" feature. With compound miter saws, the motor not only pivots left and right but it also can be tilted to either side to make beveled cuts. This feature is great for projects that require cuts to take place in two planes, such as a box with corners that are mitered and tapered or cutting crown moulding, which adds to the versatility of the machine. This pivoting of the motor, however, has caused the engineers to reconfigure the tool's guarding system. The old guard on a power miter saw was a simple yet effective shield that enclosed the blade at all times. The user always had the plastic shield between his or her hands and the blade. But when manufacturers added the pivot feature, which allows for compound cuts, the guard system had to be completely re-engineered. This new guard is much less effective than its predecessor, but it is the only solution to offering some type of protection on a saw that moves in multiple planes. Today, it makes no difference if you are making square, angled or compound cuts. The guard on all power compound miter saws exhibits a lot of blade exposure during any cutting procedure. As a user of these types of saws, you must be aware of this potentially dangerous exposure and how it affects the process of using this machine. My best guess is that most hobbyist woodworkers, cabinetmakers and furniture makers make square or angled cuts more than 98 percent of the time when using power miter saws. That means that less than 2 percent of the cuts will actually involve the "compound" feature. Now that we know that the guards on these machines are designed to accommodate the compound feature, and knowing that it creates more blade exposure, that would mean that 98 percent of the time, (under normal cutting circumstances) you are at more risk from blade exposure due to a guard that is designed for less than 2 percent of the cuts you will make. That's not a very fair trade for general safety usage. The other issue that goes along with compound saws is that you now have to keep a vigil on both the X and Y axes of a compound cut — unlike on a regular miter saw where the Y axis is permanently set. The compound feature can also spoil your accuracy with straight cuts. You should always be careful when carrying or lifting these compound machines by the motor because it can change the stop settings for the compound feature. At times it might be convenient to make multiple cuts at the same time by stacking lumber. This can safely be done by making sure that all the boards are tight against the fence and, if different in size, stacked from the largest on the bottom to the smallest on the top. Be aware that there will always be some risk of inconsistencies in the size of each piece as well as accuracy of the angle of the cut. If your saw is slightly out of perpendicular it will cause the board on top to be different than the board on the bottom. When accuracy matters I would never stack-cut. How to Add Accuracy and Safety Lumber with bows, twists, cups or warps can be especially challenging to cut on a miter saw. Remember: There are rules for keeping your stock under control. If your wood has a bow or an edge that is not straight, it is very important that the board be situated so that the flattest or straightest part of the board is at the point of contact with the blade. This will prevent pinching. Never make any cut unless the material is secured on the table and against the fence (see the photo below). Straight edges equal more control. When you place a piece of stock against the fence of the power miter saw, always put the straightest edge against the fence. f the stock is rough, make sure that the board contacts the fence for a distance that is equal to the length of the saw's built-in fence on one side of the blade. Shown is a board that should be flipped over. popularwoodworking.com ■ 49 CIRCLE #100 ON FREE INFORMATION CARD. |