Popular Woodworking 2008-04 № 168, страница 58

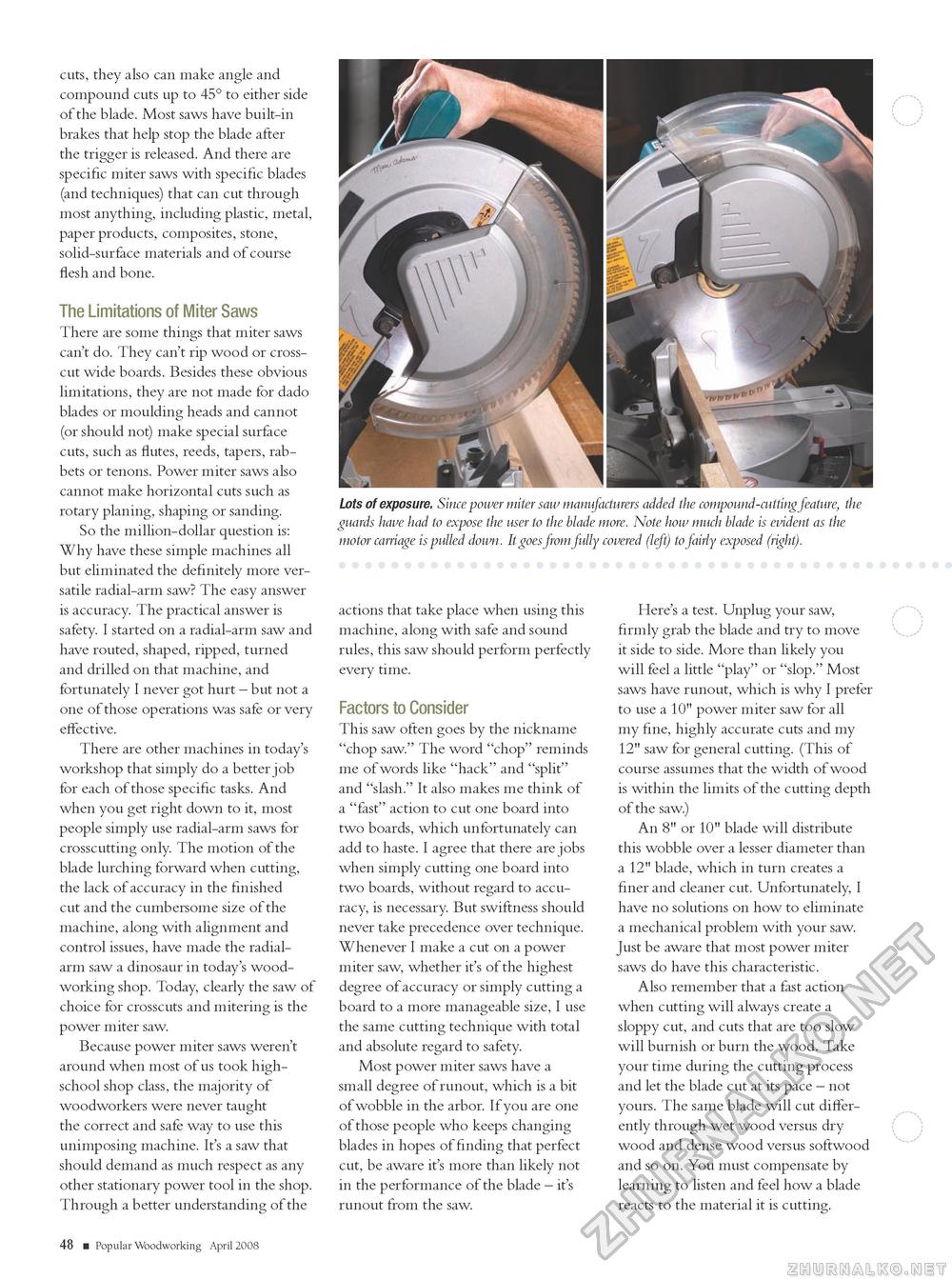

Lots of exposure. Since power miter saw manufacturers added the compound-cutting feature, the guards have had to expose the user to the blade more. Note how much blade is evident as the motor carriage is pulled down. It goes from fully covered (left) to fairly exposed (right). cuts, they also can make angle and compound cuts up to 45° to either side of the blade. Most saws have built-in brakes that help stop the blade after the trigger is released. And there are specific miter saws with specific blades (and techniques) that can cut through most anything, including plastic, metal, paper products, composites, stone, solid-surface materials and of course flesh and bone. The Limitations of Miter Saws There are some things that miter saws can't do. They can't rip wood or crosscut wide boards. Besides these obvious limitations, they are not made for dado blades or moulding heads and cannot (or should not) make special surface cuts, such as flutes, reeds, tapers, rabbets or tenons. Power miter saws also cannot make horizontal cuts such as rotary planing, shaping or sanding. So the million-dollar question is: Why have these simple machines all but eliminated the definitely more versatile radial-arm saw? The easy answer is accuracy. The practical answer is safety. I started on a radial-arm saw and have routed, shaped, ripped, turned and drilled on that machine, and fortunately I never got hurt — but not a one of those operations was safe or very effective. There are other machines in today's workshop that simply do a better job for each of those specific tasks. And when you get right down to it, most people simply use radial-arm saws for crosscutting only. The motion of the blade lurching forward when cutting, the lack of accuracy in the finished cut and the cumbersome size of the machine, along with alignment and control issues, have made the radial-arm saw a dinosaur in today's woodworking shop. Today, clearly the saw of choice for crosscuts and mitering is the power miter saw. Because power miter saws weren't around when most of us took high-school shop class, the majority of woodworkers were never taught the correct and safe way to use this unimposing machine. It's a saw that should demand as much respect as any other stationary power tool in the shop. Through a better understanding of the actions that take place when using this machine, along with safe and sound rules, this saw should perform perfectly every time. Factors to Consider This saw often goes by the nickname "chop saw." The word "chop" reminds me of words like "hack" and "split" and "slash." It also makes me think of a "fast" action to cut one board into two boards, which unfortunately can add to haste. I agree that there are jobs when simply cutting one board into two boards, without regard to accuracy, is necessary. But swiftness should never take precedence over technique. Whenever I make a cut on a power miter saw, whether it's of the highest degree of accuracy or simply cutting a board to a more manageable size, I use the same cutting technique with total and absolute regard to safety. Most power miter saws have a small degree of runout, which is a bit of wobble in the arbor. If you are one of those people who keeps changing blades in hopes of finding that perfect cut, be aware it's more than likely not in the performance of the blade — it's runout from the saw. Here's a test. Unplug your saw, firmly grab the blade and try to move it side to side. More than likely you will feel a little "play" or "slop." Most saws have runout, which is why I prefer to use a 10" power miter saw for all my fine, highly accurate cuts and my 12" saw for general cutting. (This of course assumes that the width of wood is within the limits of the cutting depth of the saw.) An 8" or 10" blade will distribute this wobble over a lesser diameter than a 12" blade, which in turn creates a finer and cleaner cut. Unfortunately, I have no solutions on how to eliminate a mechanical problem with your saw. Just be aware that most power miter saws do have this characteristic. Also remember that a fast action when cutting will always create a sloppy cut, and cuts that are too slow will burnish or burn the wood. Take your time during the cutting process and let the blade cut at its pace — not yours. The same blade will cut differently through wet wood versus dry wood and dense wood versus softwood and so on. You must compensate by learning to listen and feel how a blade reacts to the material it is cutting. 48 ■ Popular Woodworking April 2008 MX |