Popular Woodworking 2008-08 № 170, страница 39

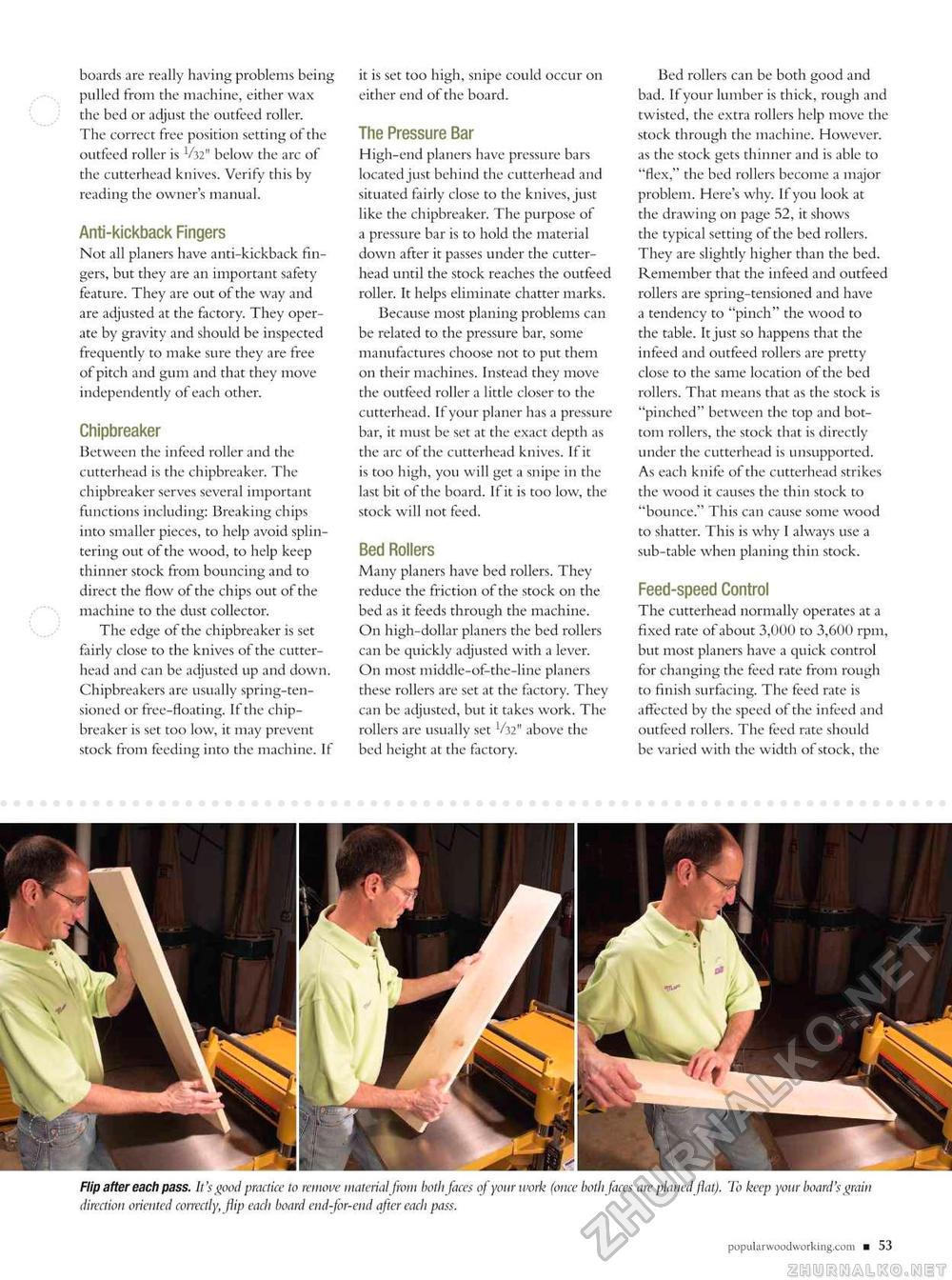

boards are really having problems being pulled from the machine, either wax the bed or adjust the outfeed roller. The correct free position setting of the outfeed roller is V32" below the arc of the cutterhead knives. Verify this by reading the owner's manual. Anti-kickback Fingers Not all planers have anti-kickback fingers, but they are an important safety feature. They are out of the way and are adjusted at the factory. They operate by gravity and should be inspected frequently to make sure they are free of pitch and gum and that they move independently of each other. Chipbreaker Between the infeed roller and the cutterhead is the chipbreaker. The chipbreaker serves several important functions including: Breaking chips into smaller pieces, to help avoid splintering out of the wood, to help keep thinner stock from bouncing and to direct the flow of the chips out of the machine to the dust collector. The edge of the chipbreaker is set fairly close to the knives of the cutterhead and can be adjusted up and down. Chipbreakers are usually spring-ten-sioned or free-floating. If the chip-breaker is set too low, it may prevent stock from feeding into the machine. If it is set too high, snipe could occur on either end of the board. The Pressure Bar High-end planers have pressure bars located just behind the cutterhead and situated fairly close to the knives, just like the chipbreaker. The purpose of a pressure bar is to hold the material down after it passes under the cutterhead until the stock reaches the outfeed roller. It helps eliminate chatter marks. Because most planing problems can be related to the pressure bar, some manufactures choose not to put them on their machines. Instead they move the outfeed roller a little closer to the cutterhead. If your planer has a pressure bar, it must be set at the exact depth as the arc of the cutterhead knives. If it is too high, you will get a snipe in the last bit of the board. If it is too low, the stock will not feed. Bed Rollers Many planers have bed rollers. They reduce the friction of the stock on the bed as it feeds through the machine. On high-dollar planers the bed rollers can be quickly adjusted with a lever. On most middle-of-the-line planers these rollers are set at the factory. They can be adjusted, but it takes work. The rollers are usually set V32" above the bed height at the factory. Bed rollers can be both good and bad. If your lumber is thick, rough and twisted, the extra rollers help move the stock through the machine. However, as the stock gets thinner and is able to "flex," the bed rollers become a major problem. Here's why. If you look at the drawing oil page 52, it shows the typical setting of the bed rollers. They are slightly higher than the bed. Remember that the infeed and outfeed rollers are spring-tensioned and have a tendency to "pinch" the wood to the table. It just so happens that the infeed and outfeed rollers are pretty close to the same location of the bed rollers. That means that as the stock is "pinched" between the top and bottom rollers, the stock that is directly under the cutterhead is unsupported. As each knife of the cutterhead strikes the wood it causes the thin stock to "bounce." This can cause some wood to shatter. This is why I always use a sub-table when planing thin stock. Feed-speed Control The cutterhead normally operates at a fixed rate of about 3,000 to 3,600 rpm, but most planers have a quick control for changing the feed rate from rough to finish surfacing. The feed rate is affected by the speed of the infeed and outfeed rollers. The feed rate should be varied with the width of stock, the |