Popular Woodworking 2008-08 № 170, страница 38

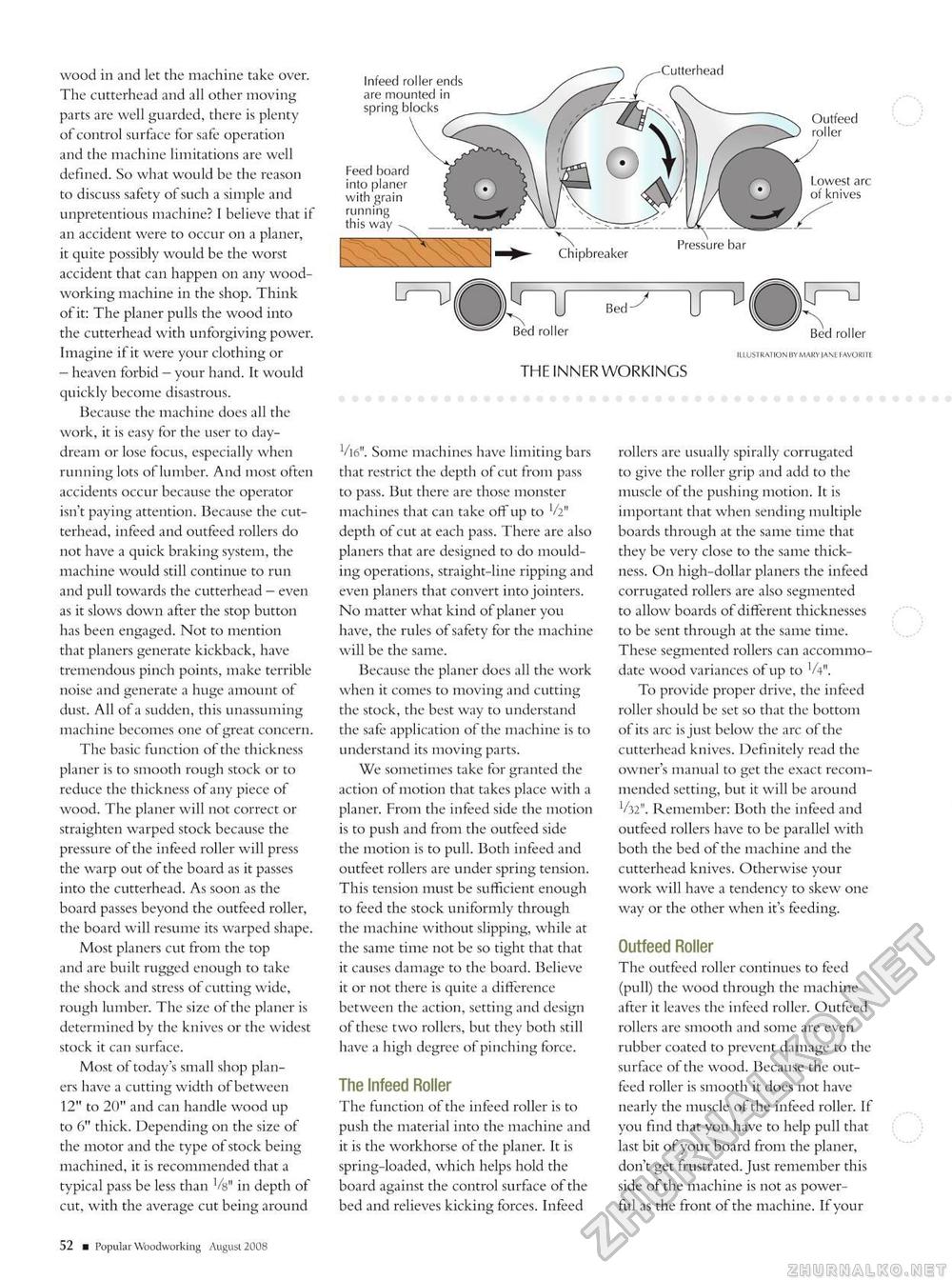

THE INNER WORKINGS wood in and let the machine take over. The cutterhead and all other moving parts are well guarded, there is plenty of control surface for safe operation and the machine limitations are well defined. So what would be the reason to discuss safety of such a simple and unpretentious machine? I believe that if an accident were to occur on a planer, it quite possibly would be the worst accident that can happen on any woodworking machine in the shop. Think of it: The planer pulls the wood into the cutterhead with unforgiving power. Imagine if it were your clothing or - heaven forbid - your hand. It would quickly become disastrous. Because the machine does all the work, it is easy for the user to daydream or lose focus, especially when running lots of lumber. And most often accidents occur because the operator isn't paying attention. Because the cutterhead, infeed and outfeed rollers do not have a quick braking system, the machine would still continue to run and pull towards the cutterhead - even as it slows down after the stop button has been engaged. Not to mention that planers generate kickback, have tremendous pinch points, make terrible noise and generate a huge amount of dust. All of a sudden, this unassuming machine becomes one of great concern. The basic function of the thickness planer is to smooth rough stock or to reduce the thickness of any piece of wood. The planer will not correct or straighten warped stock because the pressure of the infeed roller will press the warp out of the board as it passes into the cutterhead. As soon as the board passes beyond the outfeed roller, the board will resume its warped shape. Most planers cut from the top and are built rugged enough to take the shock and stress of cutting wide, rough lumber. The size of the planer is determined by the knives or the widest stock it can surface. Most of today's small shop planers have a cutting width of between 12" to 20" and can handle wood up to 6" thick. Depending on the size of the motor and the type of stock being machined, it is recommended that a typical pass be less than Vs" in depth of cut, with the average cut being around /l6". Some machines have limiting bars that restrict the depth of cut from pass to pass. But there are those monster machines that can take off up to V2" depth of cut at each pass. There are also planers that are designed to do moulding operations, straight-line ripping and even planers that convert into jointers. No matter what kind of planer you have, the rules of safety for the machine will be the same. Because the planer does all the work when it comes to moving and cutting the stock, the best way to understand the safe application of the machine is to understand its moving parts. We sometimes take for granted the action of motion that takes place with a planer. From the infeed side the motion is to push and from the outfeed side the motion is to pull. Both infeed and outfeet rollers are under spring tension. This tension must be sufficient enough to feed the stock uniformly through the machine without slipping, while at the same time not be so tight that that it causes damage to the board. Believe it or not there is quite a difference between the action, setting and design of these two rollers, but they both still have a high degree of pinching force. The Infeed Roller The function of the infeed roller is to push the material into the machine and it is the workhorse of the planer. It is spring-loaded, which helps hold the board against the control surface of the bed and relieves kicking forces. Infeed rollers are usually spirally corrugated to give the roller grip and add to the muscle of the pushing motion. It is important that when sending multiple boards through at the same time that they be very close to the same thickness. On high-dollar planers the infeed corrugated rollers are also segmented to allow boards of different thicknesses to be sent through at the same time. These segmented rollers can accommodate wood variances of up to V4". To provide proper drive, the infeed roller should be set so that the bottom of its arc is just below the arc of the cutterhead knives. Definitely read the owner's manual to get the exact recommended setting, but it will be around V32". Remember: Both the infeed and outfeed rollers have to be parallel with both the bed of the machine and the cutterhead knives. Otherwise your work will have a tendency to skew one way or the other when it's feeding. Outfeed Roller The outfeed roller continues to feed (pull) the wood through the machine after it leaves the infeed roller. Outfeed rollers are smooth and some are even rubber coated to prevent damage to the surface of the wood. Because the out-feed roller is smooth it does not have nearly the muscle of the infeed roller. If you find that you have to help pull that last bit of your board from the planer, don't get frustrated. Just remember this side of the machine is not as powerful as the front of the machine. If your |