Popular Woodworking 2008-08 № 170, страница 49

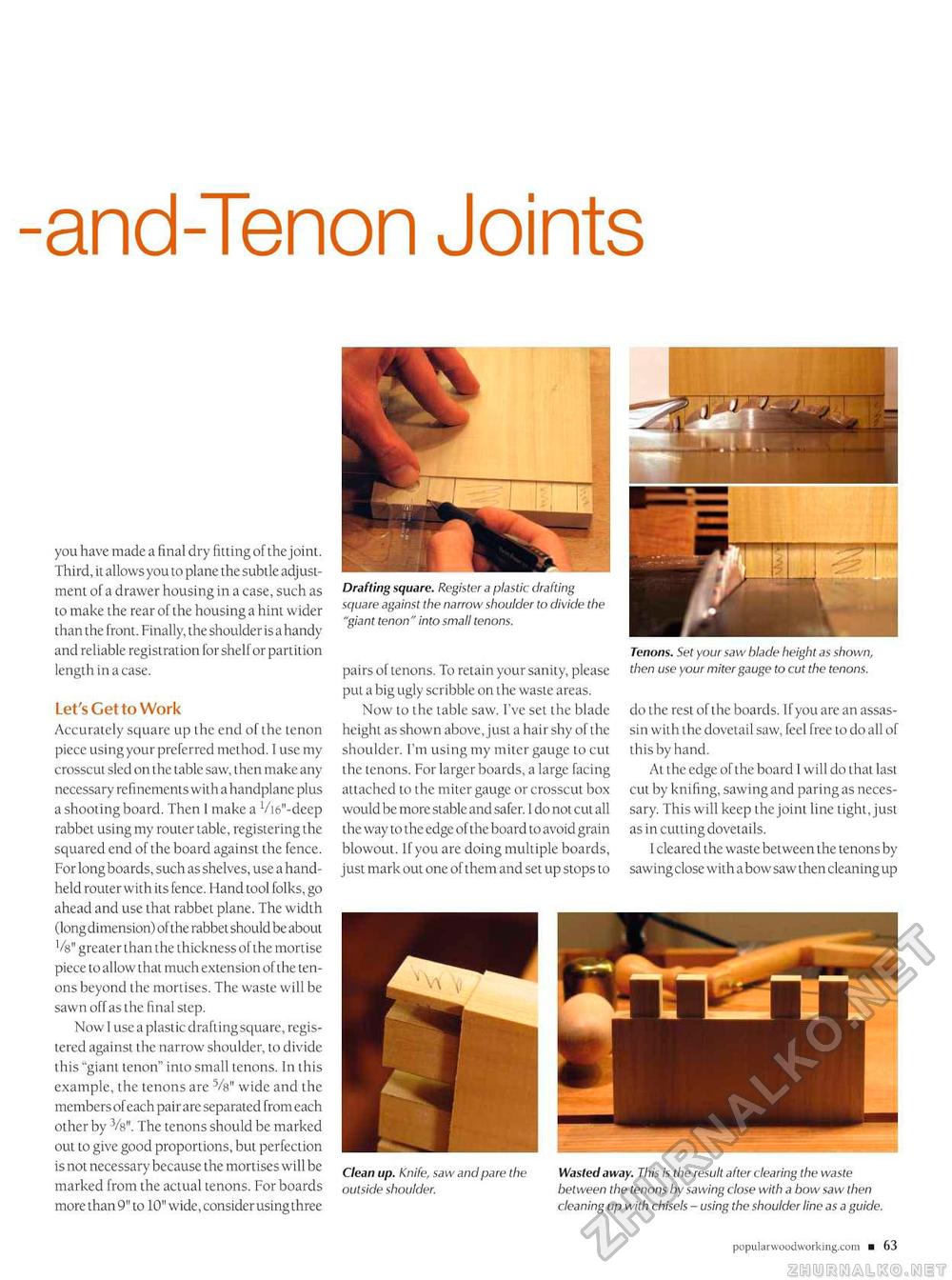

-and-Tenon Jointsyou have made a final dry fitting of the joint. Third, it allows you to plane the subtle adjustment of a drawer housing in a case, such as to make the rear of the housing a hint wider than the front. Finally, the shoulder is a handy and reliable registration for shelf or partition length in a case. Let's Get to Work Accurately square up the end of the tenon piece using your preferred method. I use my crosscut sled on the table saw, then make any necessary refinements with a handplane plus a shooting board. Then I make a Vi6"-deep rabbet using my router table, registering the squared end of the board against the fence. For long boards, such as shelves, use a handheld router with its fence. Hand tool folks, go ahead and use that rabbet plane. The width (longdimension) of the rabbet should be about V8" greater than the thickness of the mortise piece to allow that much extension of the tenons beyond the mortises. The waste will be sawn off as the final step. Now I use a plastic drafting square, registered against the narrow shoulder, to divide this "giant tenon" into small tenons. In this example, the tenons are Vs" wide and the members of each pair are separated from each other by Ys". The tenons should be marked out to give good proportions, but perfection is not necessary because the mortises will be marked from the actual tenons. For boards more than 9" to 10" wide, consider using three Drafting square. Register a plastic drafting square against the narrow shoulder to divide the "giant tenon" into small tenons. pairs of tenons. To retain your sanity, please put a big ugly scribble on the waste areas. Now to the table saw. I've set the blade height as shown above, just a hair shy of the shoulder. I'm using my miter gauge to cut the tenons. For larger boards, a large facing attached to the miter gauge or crosscut box would be more stable and safer. 1 do not cut all the way to the edge of the board to avoid grain blowout. If you are doing multiple boards, just mark out one of them and set up stops to Tenons. Set your saw blade height as shown, then use your miter gauge to cut the tenons. do the rest of the boards. If you are an assassin with the dovetail saw, feel free to do all of this by hand. At the edge of the board I will do that last cut by knifing, sawing and paring as necessary. This will keep the joint line tight, just as in cutting dovetails. I cleared the waste between the tenons by sawing close with a bow saw then cleaning up Clean up. Knife, saw and pare the Wasted away. This is the result after clearing the waste outside shoulder. between the tenons by sawing close with a bow saw then cleaning up with chisels - using the shoulder line as a guide. |