Popular Woodworking 2008-10 № 171, страница 11

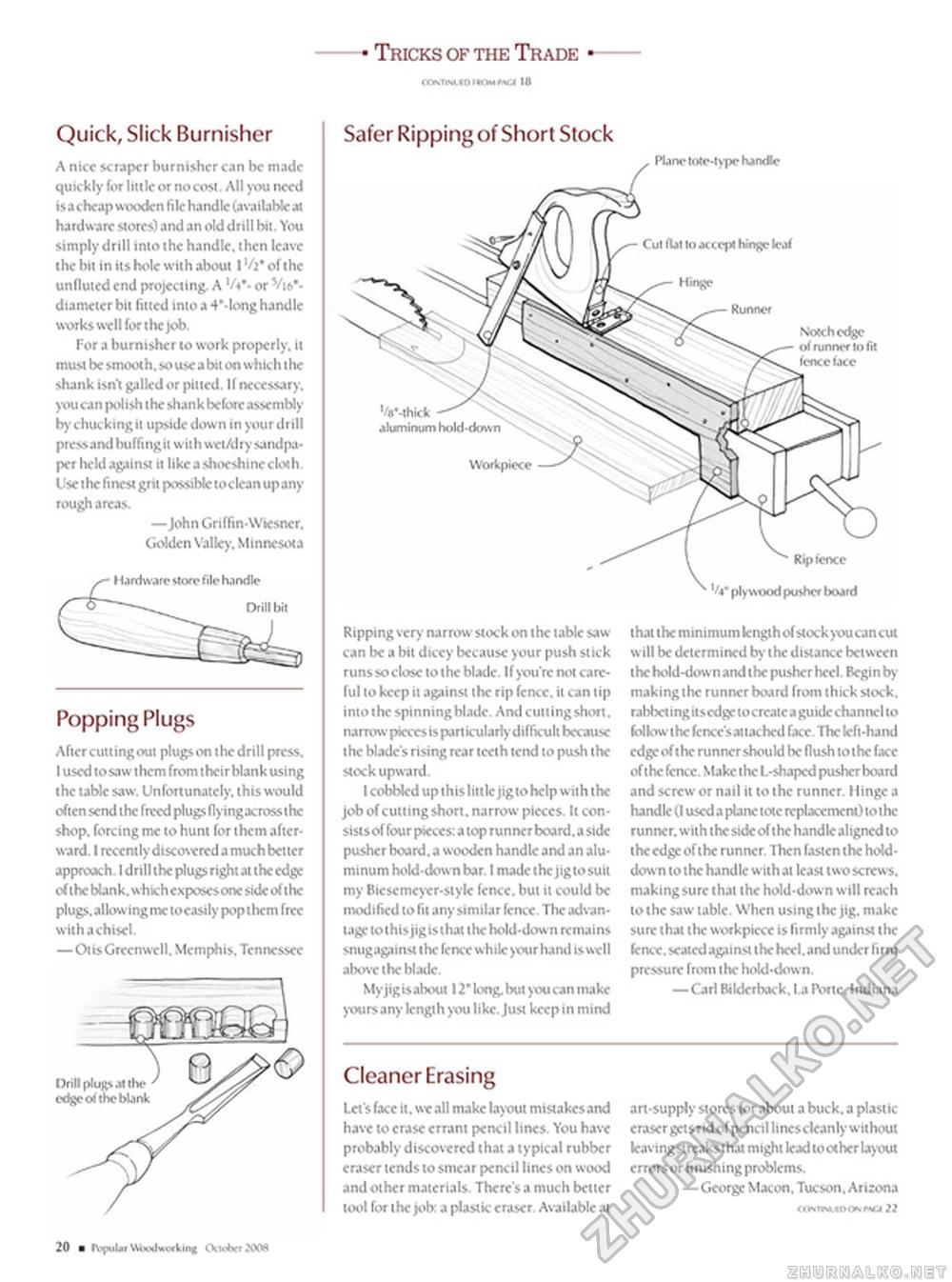

Quick, Slick Burnisher A nicc scraper burnisher can be made quickly for liule or no cost. All you need isacheap wooden file handle (available at hardware stores) and an old drill bit. You simply drill into the handle, then leave the bit in its hole with about 1 Vj* of the unfluted end projecting. A '/«*- or Vie*, diameter bit fitted into a 4*-long handle works well for the job. For a burnisher to work properly, it must be smooth, so use a bit on which the shank isn't galled or pitted. If necessary, you can polish the shank before assembly by chucking it upside down in your drill pressand huffingii with wet/dry sandpaper held against it like a shoeshine cloth. Use the finest grit possible toclean up any rough areas. —John GriffinAViesner. Golden Valley. Minnesota Popping Plugs After cutting out plugs on the drill press. I used to saw them from their blank using the table saw. Unfortunately, this would often send the freed plugs flyingacross the shop, forcing me to hunt for them afterward. I recently discovered a much better approach. 1 drill the plugs right at the edge of the blank, which exposes one side of the plugs.allowingmctocasilypopthcmfrec with a chisel. —Ot is Grccnwcll. Memphis. Tennessee Ripping very narrow slock on the table saw can be a bit dicey because your push slick runs so close to the blade. If you're not careful to keep il against the rip fence, it can tip into the spinning blade. And cutting short, narrow picccsis particularly difficult because the blade's rising rear teeth tend to push the stock upward. I cobbled up this little jig to help with the job of cutting short, narrow pieces. It con-sistsof four pieces: a top runner board, a side pusher board, a wooden handle and an aluminum hold-down bar. I made the jig tosuit my Bicscmeyer-style fence, but il could be modified to fit any similar fence. The advantage to this jigis that the hold-down remains snug against the fence while your hand is well above the blade. Myjigisabout 12* long, but you can make yoursany length you like. Just keep in mind lhal the minimum lenglhofstockyoucancut will be determined by the distance between the hold-down and the pusher heel. Begin by making the runner board from thick stock, rabbctingitscdgctocreatcaguidcchannclto follow the fcncc'saltachcd face. The left-hand edge of the runner should be flush to the face of the fence. Make the L-shapcd pusher board and screw or nail it to the runner. Hinge a handle (I used a plane lotc replacement) to the runner, with the side of the handle aligned to the edge of ihe runner. Then fasten the hold-down to the handle with at least two screws, making sure thai the hold-down will reach lo the saw table. When using the jig. make sure that the workpiccc is firmly against the fence, seated against the heel.and under firm pressure from the hold-down. —Carl Bilderbock. l.a POrte. Indiana Cleaner Erasing Let's face it. we all make layout mistakes and have to erase errant pencil lines. You have probably discovered that a typical rubber eraser lends lo smear pencil lines on wood and other materials. There's a much better tool for the job: a plastic eraser. Available at art-supply stores for about a buck, a plastic eraser gets rid of pencil linescleanly without leavingsireaksthat might lead toother layout errors or finishing problems. —George Macon. Tucson, Arizona (rximciooMMCi 22 ■ Tricks of the Trade « Safer Ripping of Short Stock Plane tote-type handle Cut flat lo acc epl hinge leaf 'V-thick Workpiece Notch edge of runner lofit fence face Rip fence '/a* plywood pusher board 20 ■ r\-poUi WM*mUo| OiwhrtXKW |