Popular Woodworking 2008-10 № 171, страница 8

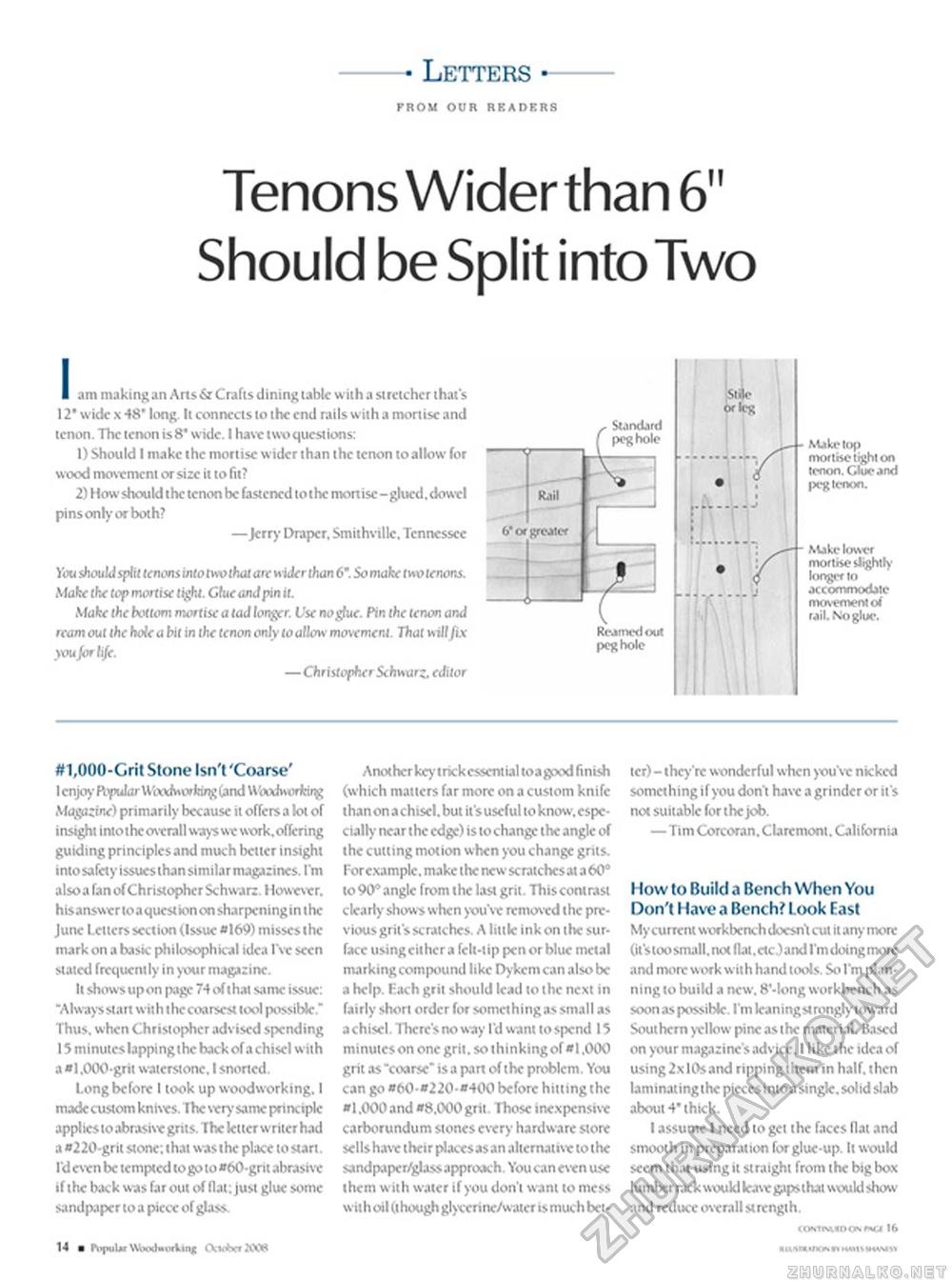

- Letters • FROM OUR READERS Tenons Wider than 6" Should be Split into Two lam making an Aits & Crafts dining table with a strctchcr that's 12* wide x 48* long. It connects to the end rails with a mortise and tenon. The tenon is 8* wide. I have two questions: 1) Should I make the mortise wider than the tenon to allow for wood movement or size it to fit? 2) How should the tenon be fastened to the mortise-glued, dowel pins only or both? —jerry Draper, Smithvillc, Tennessee You should split tenons into (mo thai art wider than 6". So make two tenons. Make the top mortise iigfil. Glue and pin it. Make the bottom mortise a tad longer. Use nogfue. Pin the tenon and ream out the Me a bit in the tenon only to allow movement. That v>ill fix .you for life. —Christopher Sehwurz. editor #1,000-Gril Stone Isn't 'Coarse' I enjoy ftyulor (and Wlnxhsorfcrtf M^tjucme) primarily because it offers a lot of insight intothe overall wayswvwork.offcring guiding principles and much better insight intosafety issues than similar magazines. I'm alsoa fan of Christopher Schwa rz. Howicver. hisanswer toaqucstion on sharpeningin the June Letters section (Issue »169) misses the mark on a bask philosophical idea I've seen stated frequently in your magazine. It shows upon page 74 of that same issue: "Always start with the coarsest tool possible." Thus, when Christopher advised spending 15 m i nutes lapping t he back of a chisel wit h a *l .000-grit waterstone. I snorted. Long before I look up woodworking, I made custom knives. The very same principle applies to abrasive grits. The kllcr writer had a 0220-grit stone: that was the place to start. I'd even be tempted to go to »60-grit abrasive if the back was far out of flat: just glue some sandpaper to a piece of glass. 14 • PI^IU. JiVW Anot her kcylrickessentialtoagood finish (which matters far more on a custom knife than on a chisel, but it's useful to know, especially' near the edge) is to change the angle of the cutting motion when you change grits. For example, make the new scratches at a 60° to 90* angle from the last grit. This contrast clearly shows when you've removed the previous grit's scratches. A little ink on the surface usingcithcra felt-tip pen or blue metal marking compound like Dykcm can also be a help. Each grit should lead to the next in fairly short order for something as small as a chisel. There's no way I'd want tospend 15 minutes on one grit, so thinking of «1.000 grit as "coarse" is a pan of the problem. You can go »60-«220-*400 before hitting the «1.000 and "8.000 grit. Those inexpensive carborundum stones every hardware store sells have their places as an alternative to the sandpaper/glassapprooch. You can even use them with water if you don't want to mess with oil (though glycerine/water is much bet ter) - they're wonderful when you've nicked something if you don't have a grinder or it's not suitable for the job. —Tim Corcoran. Clarcmont. California How to Build a Bench When You Don't Have a Bench? Look East My current workbench doesn't cut it any more (it'stoosmall, not flat.ctc.)and 1'mdoingmore and more work with hand tools. So I'm planning to build a new. 8'-long workbench as soon as possible. I'm leanings! rongly toward Southern yelknv pine as the material. Based on your magazine's advice. I like the idea of using 2x 10s and ripping them in half, then laminating the piecesintoa single, solid slab about 4* thick. I assume I need to get the faces flat and smooth in preparation for glue-up. It would seem that using it straight from the big box lumber rack would lease gips that would show and reduce overall strength. COftWUOOKMCI 16 |