Popular Woodworking 2008-10 № 171, страница 12

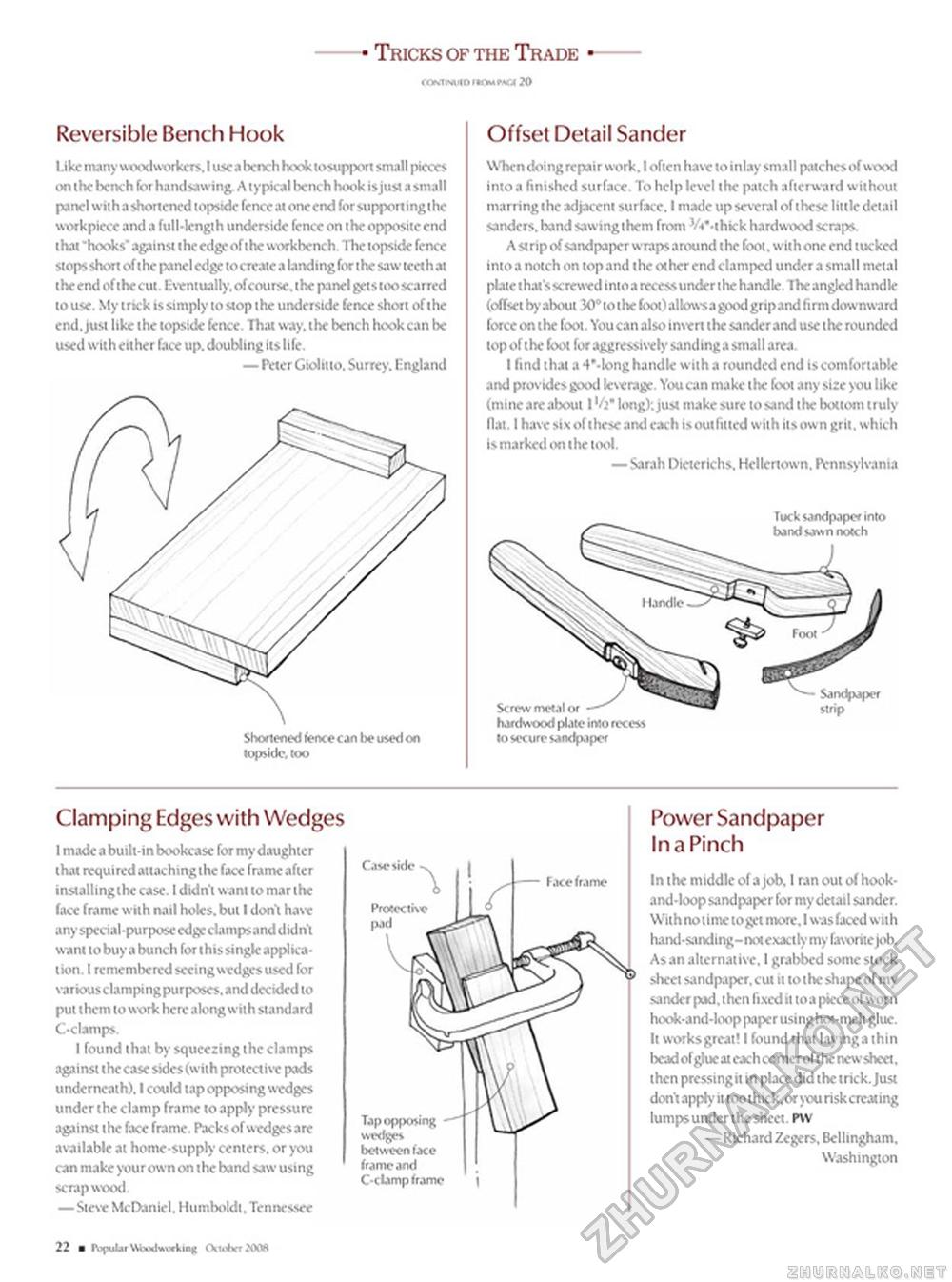

• Tricks of the Trade nMNUD nmnri 20 Reversible Bench Hook Like many woodworkers, I use a bench hook tosupport small pieces on the bench for hand vawing A typical bench hook isjust a small panel with a shortened topside fence at one end for supporting the workpiccc and a full-length underside fence on the opposite end that 'hooks' against the edge of the workbench. The topside fence stops short of the panel edge to create a landing for the saw teeth at the end of the cut. Eventually, of course, the panel gets too scarred to use. My trick is simply to stop the underside fence short of the end. just like the topside fence. That way. the bench hook can be used with either lace up. doubling its life. — Peter Giolitto. Surrey. England Shortened fence can be used on topside, too Offset Detail Sander When doing repair work. I often have to inlay small patches of wood into a finished surface. To help level the patch afterward without marring the adjacent surface. I made up several of these little detail sandcrs. band sawing them from %'.|hick hardwood scraps. A st rip of sandpaper wraps around t he loot. with one end tucked into a notch on top and the other end clamped under a small metal plate that's screwed intoa rceessunder the handle. The angled handle (offset by about 30° to the foot) allowsa good grip and f i rm downward force on the foot. You can also Invert the sander and use the rounded top of the foot fiw aggressively sanding a small area. I find that a 4Mong handle with a rounded end is comfortable and provides good leverage. You can make the foot any si2e you like (mine are about 1 xh" long); just make sure to sand the bottom truly flat. I have six of these and each is out fitted with its own grit, which is marked on the tool. — Sarah Dieterichs. Hellenown. Pennsylvania Clamping Edges with Wedges 1 made a built-in bookcase for my daughter that required attachingthe face frame after installing the case. I didn't want to mar the face frame with nail holes, but I dont has* any special-purpose edge clampsand didn't want to buy a bunch for (his single application. I remembered seeing wedges used for variousclampingpurposes. and decided lo put them to work here along with standard C-clamps. I found that by squeezing the clamps against the case sides (with protective pads underneath). I could tap opposing wedges under the clamp frame to apply pressure against the fxe frame. Packs of wedges are available at home-supply centers, or you can make yourown on the band saw using scrap wood. —Steve McDaniel. Humboldt. Tennessee 22 ■ ropuUi Wi.xxl»wkin|C t\t.*rr MM Tuck sandpaper into hand sawn notch Screw metal or hardwood plate into recess lo secure sandpaper Tap opposing between face frame and C-ciamp frame Power Sandpaper In a Pinch In the middle of a job. I ran out of hook-and-loop sandpaper for my detail sander. With notime toget more. 1 was faced with hand-sanding- not exactly' my favorite job. As an alternative, I grabbed some stock sheet sandpaper, cut it to the shape of my sander pod, then fixed it toa piece of worn hook-and-loop paper using hot-melt glue. It works great! I found that layinga thin bead of gh>e at eac h comer of t he new sheet, then pressing it in place did the trick. Just don't apply it toothick.oryou risk creating lumps under the sheet. PW — Richard Zegers, Bellingham. Washington |