Popular Woodworking 2008-10 № 171, страница 31

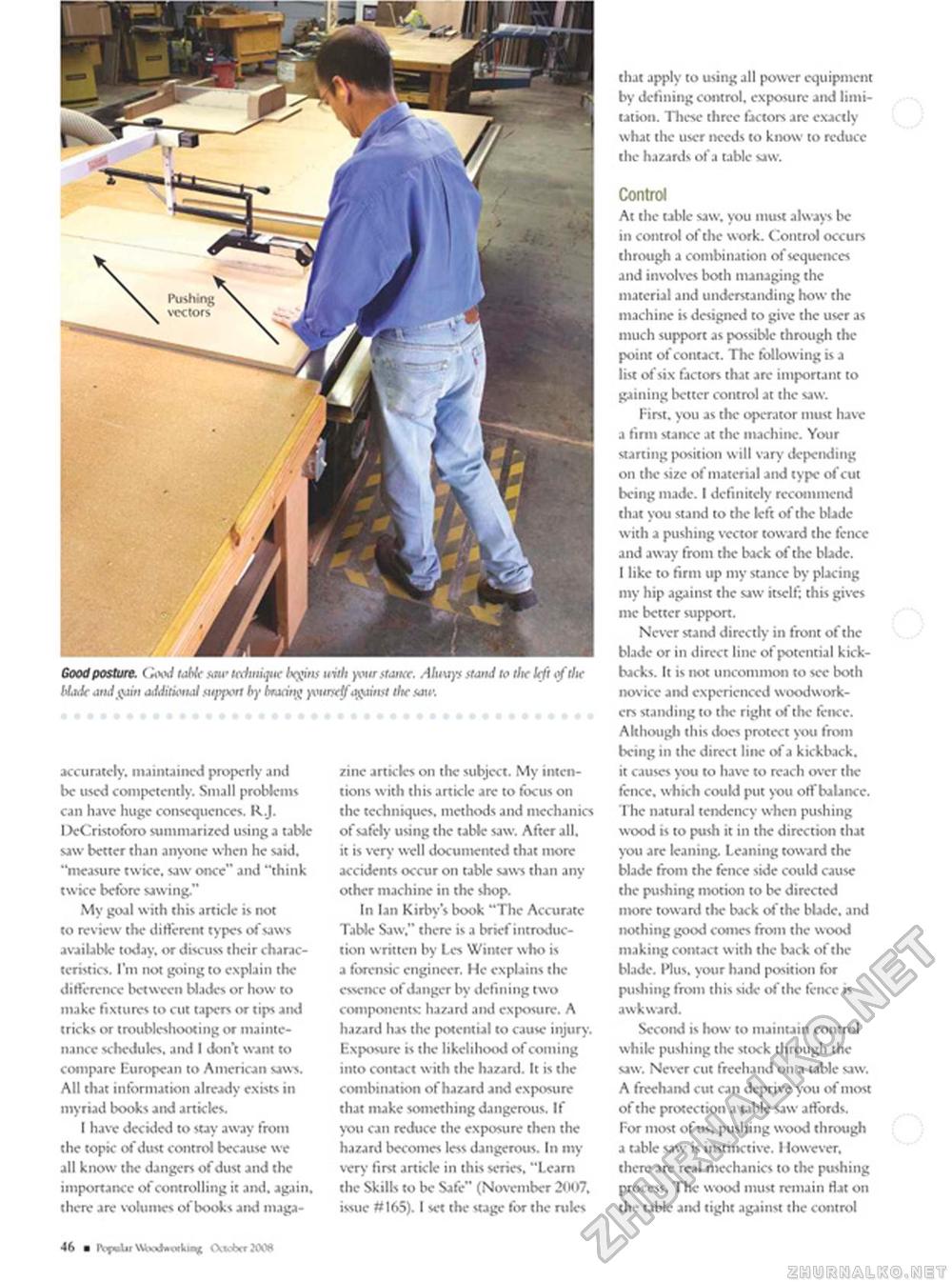

accurately. maintained properly and be used competently. Small problems can have huge consequences. R.J. DcCristoforo summarized using a table saw better than anyone when he said, "measure twice, saw once" and "think twice before sawing." My goal with this article is not to review the different types of saws available today, or discuss their characteristics. I'm not going to explain the difference between blades or how to make fixtures to cut tapers or tips and tricks or troubleshooting or maintenance schedules, and I don't want to compare European to American saws. All that information already exists in myriad books and artkks. I have deckled to stay away from the topic of dust control because we all know the dangers of dust and the importance of controlling it ami. again, there are volumes of books aisd maga zine artkles 011 the subject. My intentions with this article are to focus on the techniques, methods and ntechanics of safely using the tabk saw. After all. it is very well documented that more accidents occur on table saws than any other machine in the shop. In Ian Kirbv's book "The Accurate Table Saw." there is a brief introduction w ritten by Lcs Winter who is a forensic engineer. He explains the essence of danger by defining two components: hazard and exposure. A hazard has the potential to causc injury. Exposure is the likelihood of coming into contact with the hazard. It is the combination of hazard and exposure that nuke something dangerous. If you can reduce the exposure then the hazard becomes less dangerous. In my very first artkle in this series. "Learn the Skills to be Safe" (November 2007. issue #165). I set the stage for the rules that apply to using all power equipment by defining control, exposure and limitation. These three factors are exactly what the user needs to know to reduce the hazards of a table saw. Control At the table saw. you must always be in control of die work. Control occurs through a combination of sequences and involves both managing the material and understanding how the machine is designed to give the user as much support as possibk through the point of contact. The following is a list of six factors that are important to gaining better control at the saw. First, you as the operator must have a firm stance at the machine. Your starting position will vary depending on the size of material and type of cut being made. I definitely rcconimcnd that you stand to the kft of the blade with a pushing vector toward the fence and away from the back of the blade. I like to firm up my stance by placing my hip against the saw itself: this gives mc better support. Never stand directly in front of the blade or in direct line of potential kick-hacks. It is not uncommon to see both novice and experienced woodworkers standing to the right of the fence. Although this docs protect you from being in the direct line of a kickback, it causcs you to have to reach over the fence, whkh could put you off balance. The natural tendency when pushing wood is to push it in the direction that you are leaning Leaning toward the blade from the fence side could cause the pushing motion to be directed more toward the back of the blade, and nothing good comes from the wood making contact with the back of the blade. I'lus. your hand position for pushing from this sick of the fence is awkward. Second is how- to maintain control while pushing the stock through the saw. Never cut freehand on a table saw. A freehand cut can deprive you of most of the protection a table saw affords. For most of us, pushing wood through a table saw is instiiKtive. I low-ever, there are real mechanics to the pushing process. The wood must remain flat on the tabk and tight against the control 46 ■ fOf+mWhn*.«ku« AI.KT.W" |