Popular Woodworking 2008-12 № 173, страница 58

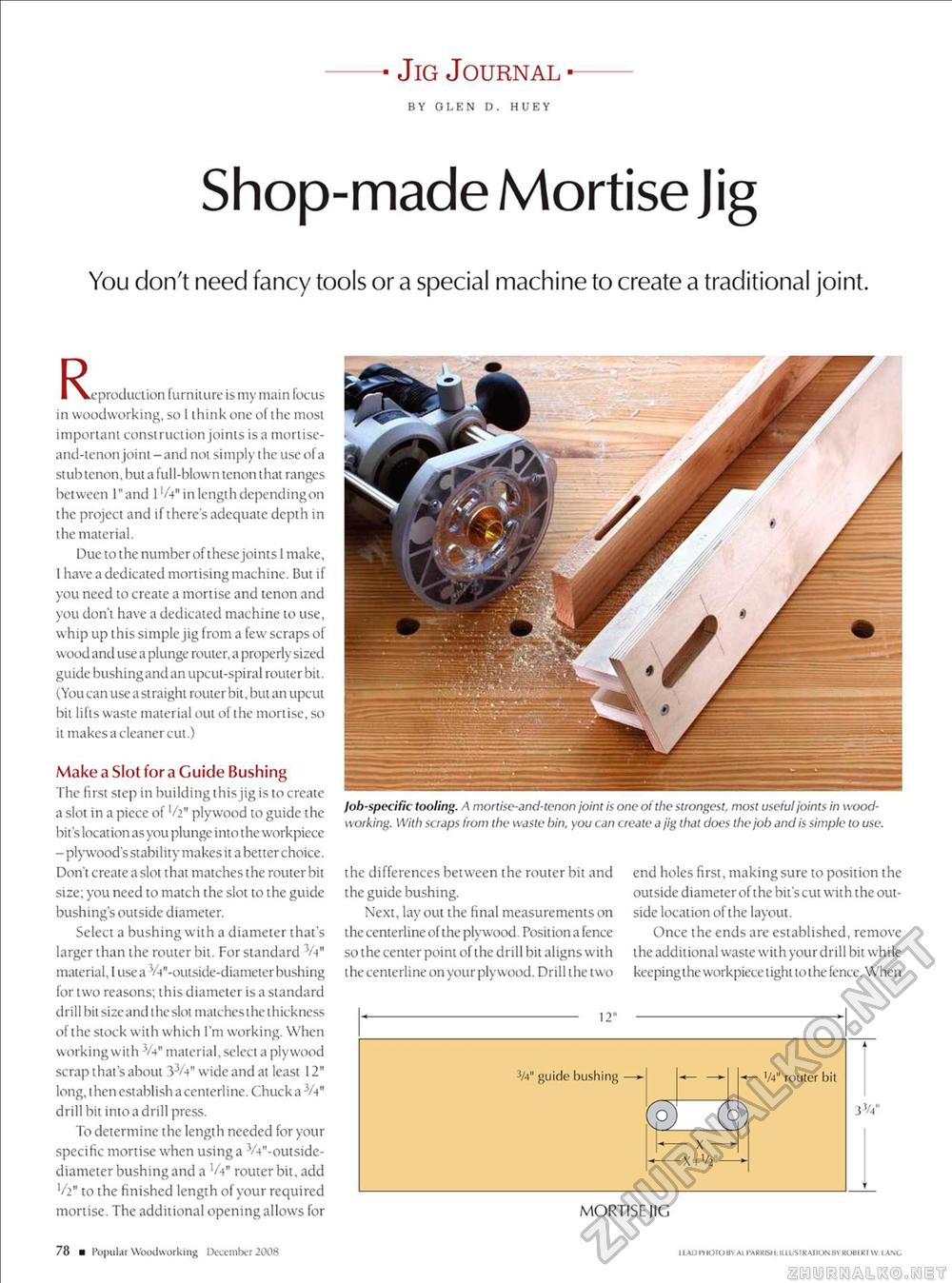

Jig JournalBY GLEN D. HUEY Shop-made Mortise JigYou don't need fancy tools or a special machine to create a traditional joint. n I Veproduction furniture is my main focus in woodworking, so 1 think one of the most important construction joints is a mortise-and-tenon joint -and not simply the use of a stub tenon, but a full-blown tenon that ranges between l"and l'A"in length depending on the project and if there's adequate depth in the material. Due to the number of these joints I make, 1 have a dedicated mortising machine. But if you need to create a mortise and tenon and you don't have a dedicated machine to use, whip up this simple jig from a few scraps of wood and use a plunge router, a properly sized guide bushingand an upcul-spiral router bit. (You can use a straight router bit, but an upcut bit lilts waste material out of the mortise, so it makes a cleaner cut.) Make a Slot for a Guide Bushing The first step in building this jig is to create a slot in a piece of V2" plywood to guide the bit's location as you plunge into t he workpiece - plywood's stability makes it a better choice. Don't create a slot that matches the router bit size; you need to match the slot to the guide bushing's outside diameter. Select a bushing with a diameter that's larger than the router bit. For standard 3A" material, 1 use a W'-outside-diameter bushing for two reasons; this diameter is a standard drill bit sizeand the slot matches the thickness of the stock with which I'm working. When working with material, select a plywood scrap that's about 33A" wide and at least 12" long, then establish a centerline. Chuck a 3/4" drill bit into a drill press. To determine the length needed for your specific mortise when using a 3A"-outside-diameter bushing and a 'A" router bit, add V21' to the finished length of your required mortise. The additional opening allows for Job-specific tooling. A mortise-and-tenon joint is one of the strongest, most useful joints in woodworking. Willi scraps from the waste bin, you can create a jig that does the job and is simple to use. the differences between the router bit and the guide bushing. Next, layout the final measurements on the centerline of the plywood. Position a fence so the center point of the drill bit aligns with the centerline on your plywood. Drill the two end holes first, making sure to position the outside diameter of the bit's cut with the outside location of the layout. Once the ends are established, remove the additional waste with your drill bit while keeping the workpiece light to the fence. When W guide bushing '/4" router bit -X + '/2" MORTISE JIG 78 ■ Popular Woodworking December 2008 LUOI'MOKJBV Al t'AKKlV I. IIIIJSIRAIION BY KOIHK1 W. IANC |