Popular Woodworking 2009-02 № 174, страница 46

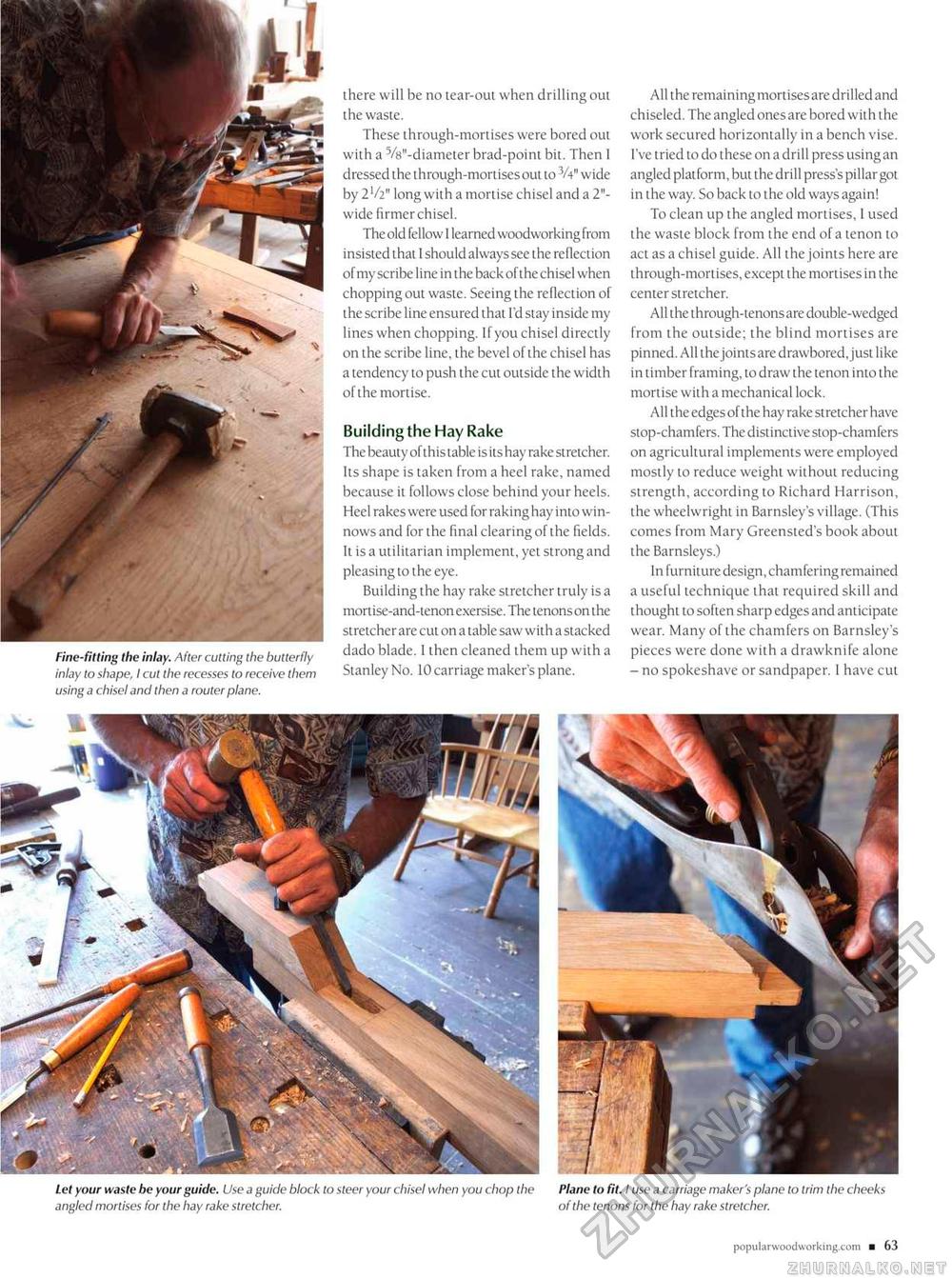

Let your waste be your guide. Use a guide block to steer your chisel when you chop the Plane to fit. I use a carriage maker's plane tc angled mortises for the hay rake stretcher. of the tenons for the hay rake stretcher. popularwoodworking.ee Fine-fitting the inlay. After cutting the butterfly inlay to shape, I cut the recesses to receive them using a chisel and then a router plane. there will be no tear-out when drilling out the waste. These through-mortises were bored out with a Vs'-diameter brad-point bit. Then 1 dressed the through-mortises out to V4" wide by 2V2" long with a mortise chisel and a 2"-wide firmer chisel. The old fellow I learned woodworking from insisted that 1 should always see the reflection of my scribe line in the back of the chisel when chopping out waste. Seeing the reflection of the scribe line ensured that I'd stay inside my lines when chopping. If you chisel directly on the scribe line, the bevel of the chisel has a tendency to push the cut outside the width of the mortise. Building the Hay Rake The beauty of this table is its hay rake stretcher. Its shape is taken from a heel rake, named because it follows close behind your heels. Heel rakes were used for raking hay into winnows and for the final clearing of the fields. It is a utilitarian implement, yet strong and pleasing to the eye. Building the hay rake stretcher truly is a mortise-and-tenon exersise. The tenons on the stretcher are cut on a table saw with a stacked dado blade. I then cleaned them up with a Stanley No. 10 carriage maker's plane. All the remaining mortises are drilled and chiseled. The angled ones are bored with the work secured horizontally in a bench vise. I've tried to do these on a drill press using an angled platform, but the drill press's pillar got in the way. So back to the old ways again! To clean up the angled mortises, I used the waste block from the end of a tenon to act as a chisel guide. All the joints here are through-mortises, except the mortises in the center stretcher. All the through-tenons are double-wedged from the outside; the blind mortises are pinned. All the joints are drawbored, just like in timber framing, to draw the tenon into the mortise with a mechanical lock. All the edges of the hay rake stretcher have stop-chamfers. The distinctive stop-chamfers on agricultural implements were employed mostly to reduce weight without reducing strength, according to Richard Harrison, the wheelwright in Barnsley's village. (This comes from Mary Greensted's book about the Barnsleys.) In furniture design, chamfering remained a useful technique that required skill and thought to soften sharp edges and anticipate wear. Many of the chamfers on Barnsley's pieces were done with a drawknife alone - no spokeshave or sandpaper. I have cut |