Popular Woodworking 2009-02 № 174, страница 47

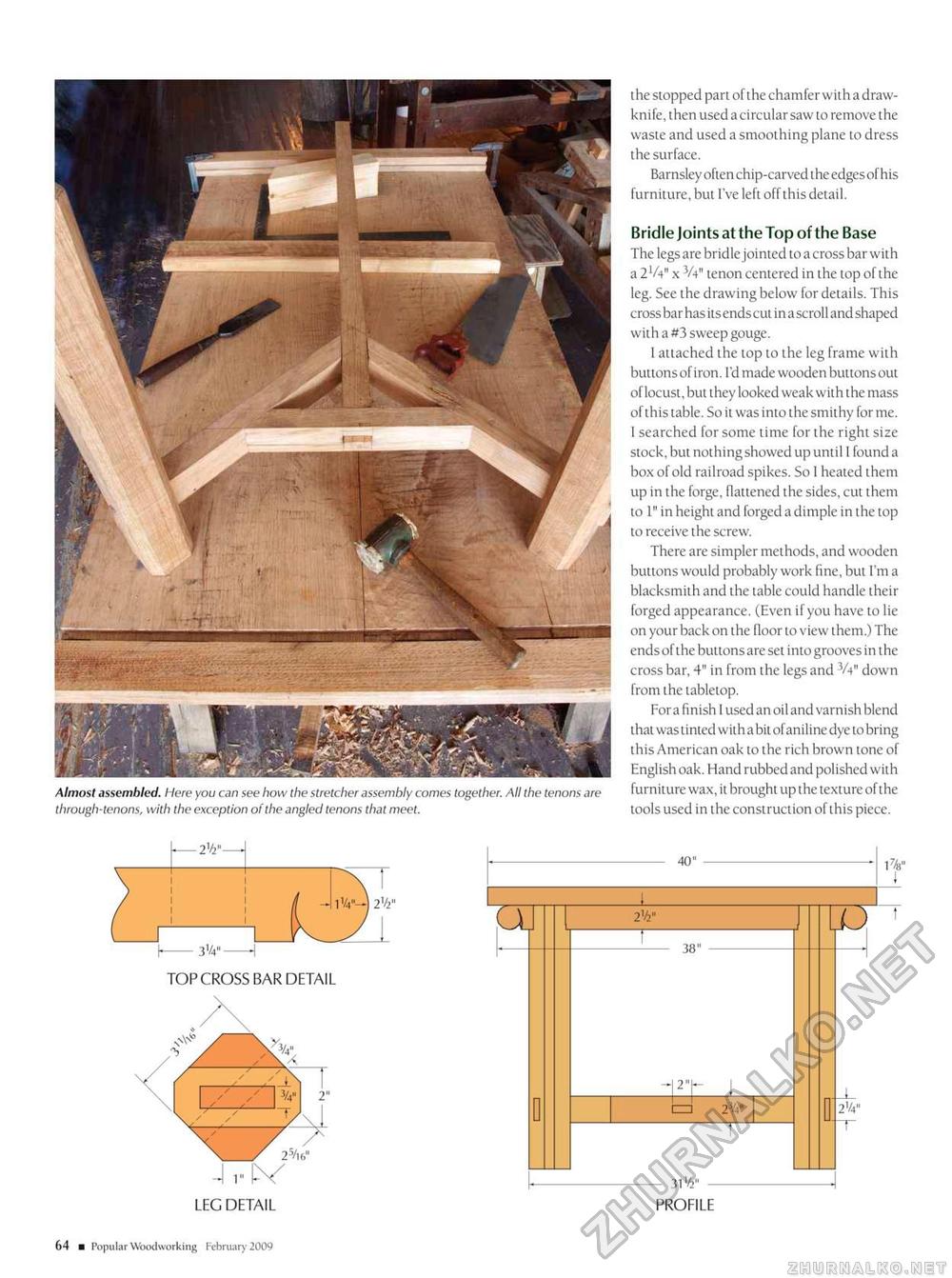

Almost assembled. Here you can see how the stretcher assembly comes together, through-tenons, with the exception of the angled tenons that meet. Almost assembled. Here you can see how the stretcher assembly comes together, through-tenons, with the exception of the angled tenons that meet. the stopped part of the chamfer with a draw-knife, then used a circular saw to remove the waste and used a smoothing plane to dress the surface. Barnsley often chip-carved the edges of his furniture, but I've left off this detail. Bridle Joints at the Top of the Base The legs are bridle jointed to a cross bar with a 2 Vy x V4" tenon centered in the top of the leg. See the drawing below for details. This cross bar has its ends cut in a scroll and shaped with a #3 sweep gouge. I attached the top to the leg frame with buttons of iron. I'd made wooden buttons out of locust, but they looked weak with the mass of this table. So it was into the smithy for me. I searched for some time for the right size stock, but nothing showed up until I found a box of old railroad spikes. So I heated them up in the forge, flattened the sides, cut them to 1" in height and forged a dimple in the top to receive the screw. There are simpler methods, and wooden buttons would probably work fine, but I'm a blacksmith and the table could handle their forged appearance. (Even if you have to lie on your back on the floor to view them.) The ends of the buttons are set into grooves in the cross bar, 4" in from the legs and V4" down from the tabletop. For a finish 1 used an oil and varnish blend that was tinted with a bit of aniline dye to bring this American oak to the rich brown tone of English oak. Hand rubbed and polished with furniture wax, it brought up the texture of the tools used in the construction of this piece. I T\ TOP CROSS BARDETAIL UT n HT la- 64 ■ Popular Woodworking February 2009 |

||||||||||||||||