Popular Woodworking 2009-04 № 175, страница 7

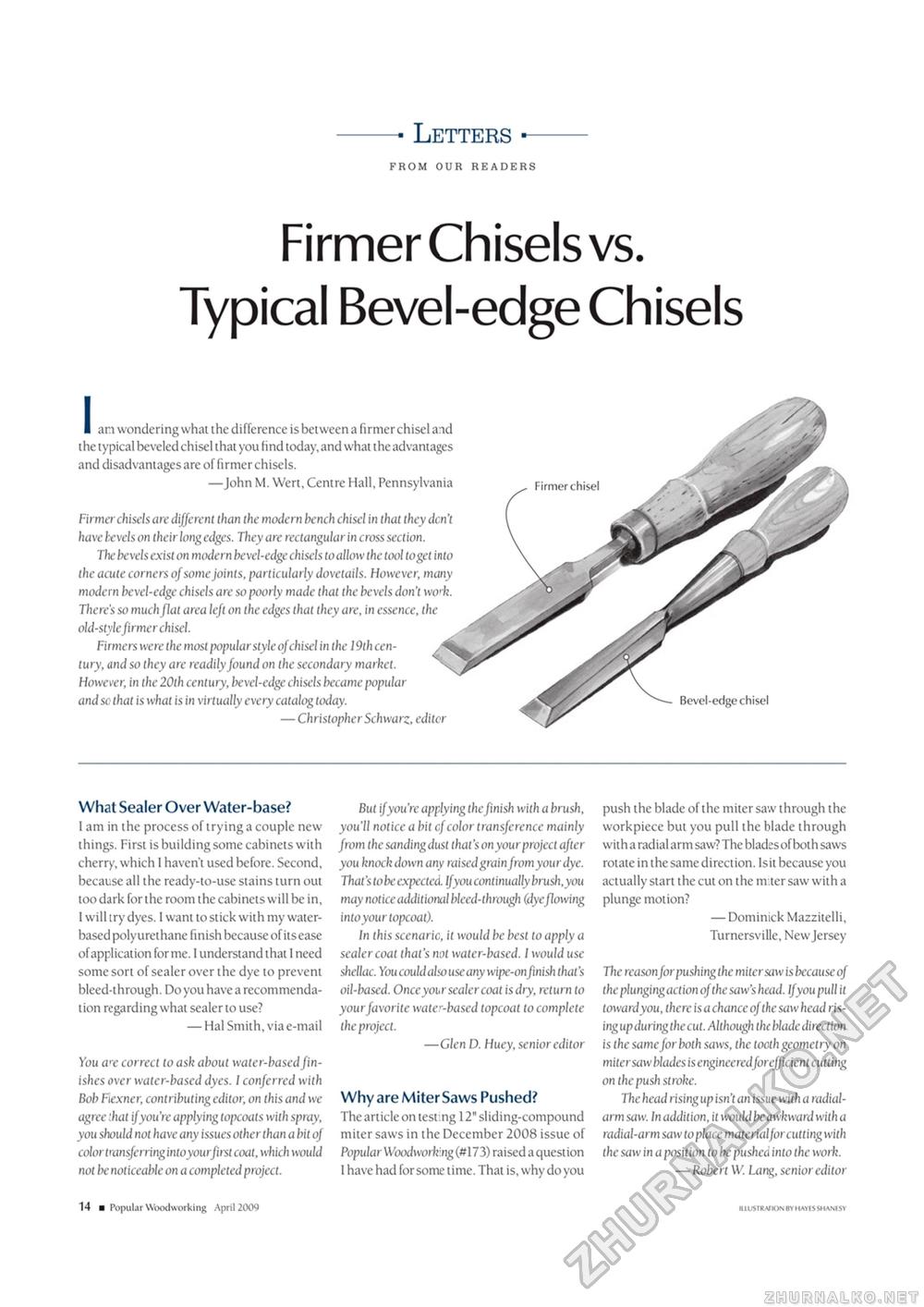

Letters FROM OUR READERS Firmer Chisels vs. Typical Bevel-edge Chisels Bcvcl-edgc chisel l an wondering what the difference is between a firmer chisel and the typical beveled chisel that you find today, and what the advantages and disadvantages are of firmer chisels. —John M. Wert, Centre Hall, Pennsylvania Firmer chisels are different than the modern bench chisel in that they dcn't have bevels on their long edges. They are rectangular in cross section. The bevels exist on modern bevel-edge chisels to allow the tool to get into the acute corners of some joints, particularly dovetails. However, many modern bevel-edge chisels are so poorly made that the bevels don't work. There's so much flat area left on the edges that they are, in essence, the old-stylefirmer chisel. Firmers were the most popular style of chisel in the 19th century, and so they are readily found on the secondary market. However, in the 20th century, bevel-edge chisels became popular and sc that is what is in virtually every catalog today. — Christopher Schwarz, editor What Sealer Over Water-base? 1 am in the process of trying a couple new things. First is building some cabinets with cherry, which 1 haven't used before. Second, because all the ready-to-use stains turn out too dark for the room the cabinets will be in, 1 will try dyes. 1 want to stick with my water-based polyurethane finish because of its ease of application forme. I understand that 1 need some sort of sealer over the dye to prevent bleed-through. Do you have a recommendation regarding what sealer to use? — Hal Smith, via e-mail You are correct to ask about water-based finishes over water-based dyes. I conferred with Bob Fiexner, contributing editor, on this and we agree 'hat if you're applying topcoats with spray, you should not have any issues other than a bit of color transferringinto your first coat, which would not be noticeable on a completed project. But if you're applying the finish with a brush, you'll notice a bit cf color transference mainly from the sanding dust that's on your project after you knockdown any raised grain from your dye. That's to be expected. If you continually brush,you may notice additional bleed-through (dyeflowing into your topcoat). In this scenario, it would be best to apply a sealer coat that's not water-based. I would use shellac. You could also use any wipe-on finish that's oil-based. Once your sealer coat is dry, return to your favorite water-based topcoat to complete the project. —Glen D. Huey, senior editor Why are Miter Saws Pushed? The article on test.ng 12" sliding-compound miter saws in the December 2008 issue of Popular Woodworking (#173) raised a question I have had for some time. That is, why do you push the blade of the miter saw through the workpiece but you pull the blade through with a radial arm saw? The blades of both saws rotate in the same direction. Isit because you actually start the cut on the m.ter saw with a plunge motion? — Dominick Mazzitelli, Turnersville, New Jersey The reason for pushing the miter saw is because of the plunging action of the saw's head. If you pull it toward you, there is a chance of the saw head ris-ing up during the cut. Although the blade direction is the same for both saws, the tooth geometry on miter saw blades is engineeredfor efficient cutting on the push stroke. The head rising up isn't an issue with a radial-arm saw. In addition, it would be awkward with a radial-arm saw to place material for cutting with the saw in a position to be pushed into the work. — Robert W. Lang, senior editor 14 ■ Popular Woodworking April 2009 ILIUSTRAIION BV MAYISSJIANISY |