Popular Woodworking 2009-06 № 176, страница 54

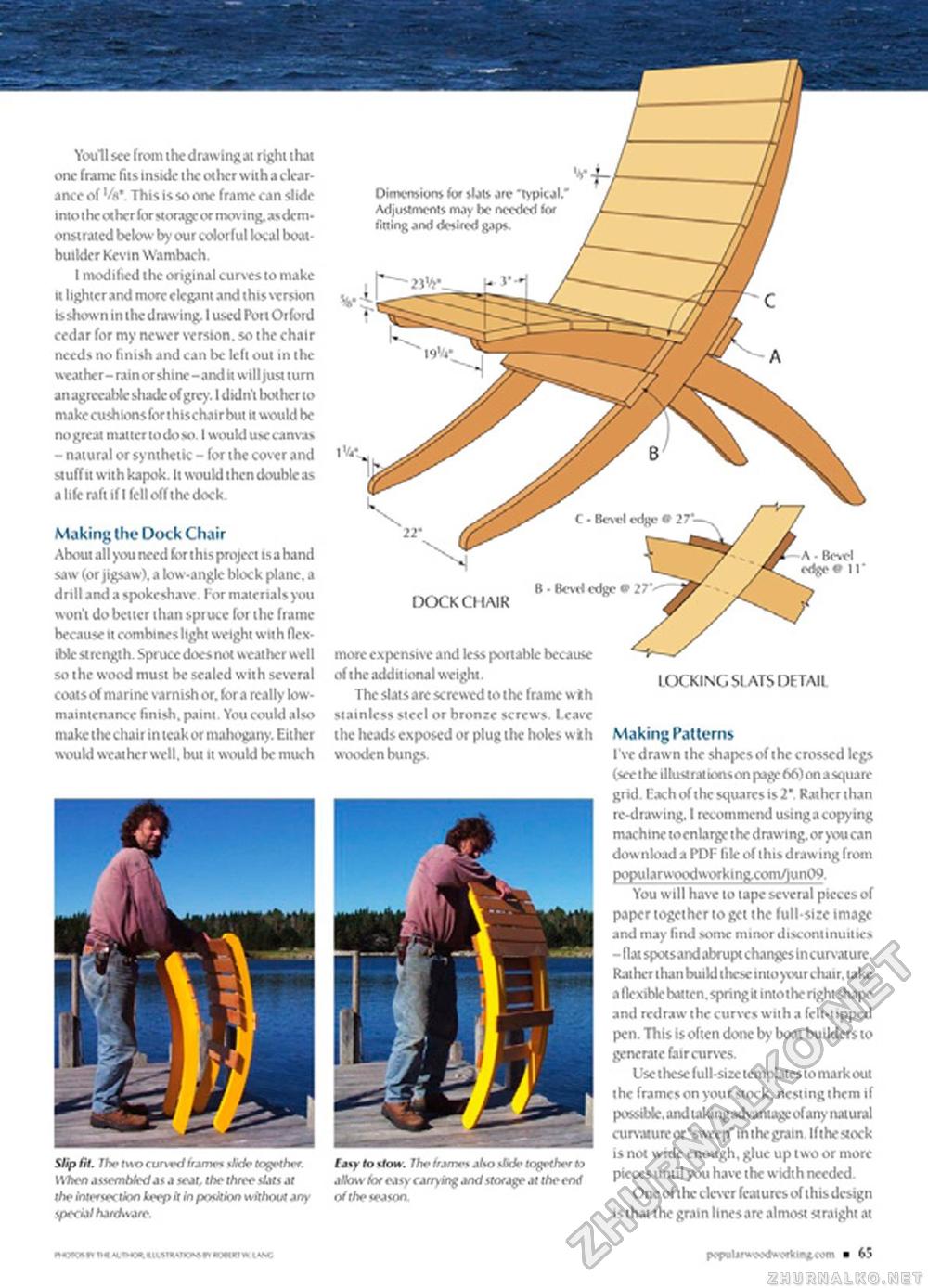

Youll see from the drawing* right that one frame fits inside the other with a clearance of '/»*. This is so one frame can slide into I he other for storage or moving, asdem-onsuaied below by our colorful local boat-builder Kevin Wamhach. I modified the original curves to make it lighterand more elegant and this version is show n i n t he d raw i ng. I used Pott Or ford cedar for my newer version, so the chair needs no finish and can be left out in the weather- rain or shine -and it will just tum an agreeable shade of grey. I didn't bother to make cushions for t his chai r but it would be no great matter todoso. I would use canvas - natural or synthetic - for the cover and stuff it with kapok. It would then double as a life raft if I fell off the dock. Making the Dock Chair About all you need for this project isa hand saw (or jigsaw), a low-angle block plane, a drill and a spokeshave. For materials you won't do better than spruce for the frame because it combines light weight with flexible strength. Spruce does not weather well so the wood musi be sealed with several coats of marine varnish or. for a really low-maintenance finish, paint You could also make the chair in teak or malio$iny. Either would weather well, hut u would he much LOCKING SLATS DETAIL Making Patterns I've drawn the shapes of the crossed legs (see the illustrations on page 66) ona square grid. Each of the squares is 2* Rather than re-drawing. I recommend usinga copying machine toenlarge the drawing, or you can dow nload a PDF file of this drawing from popularwpodwpcking.com/iun09. You will have to tape several picccs of paper together to get the full-size image - flat spots and abrupt changes In curvature. Rather than build these intoyour chair, lake a flexible batten, spring it intothc right shape and redraw the curves with a felt-tipped pen. This is often done by boat builders to generate fair curves. Use these full-size templates to mark out the frameson your stock, nestingthem if possible, and ukingadvantage of any natural curvature or "sweep" in ihe grain Ifthe stock is not wide enough, glue up two or more pieces until you have the width needed. One of the clever features of this design is that the grain llnesare almost straight at more expensive and less portable because of t he addii ional weight. The slats arc screwed to the frame with stainless steel or bronze screws. Leave the heads exposed or plug the holes with wooden bungs popo li nfwthvMt utieom ■ (5 |