Popular Woodworking 2009-08 № 177, страница 8

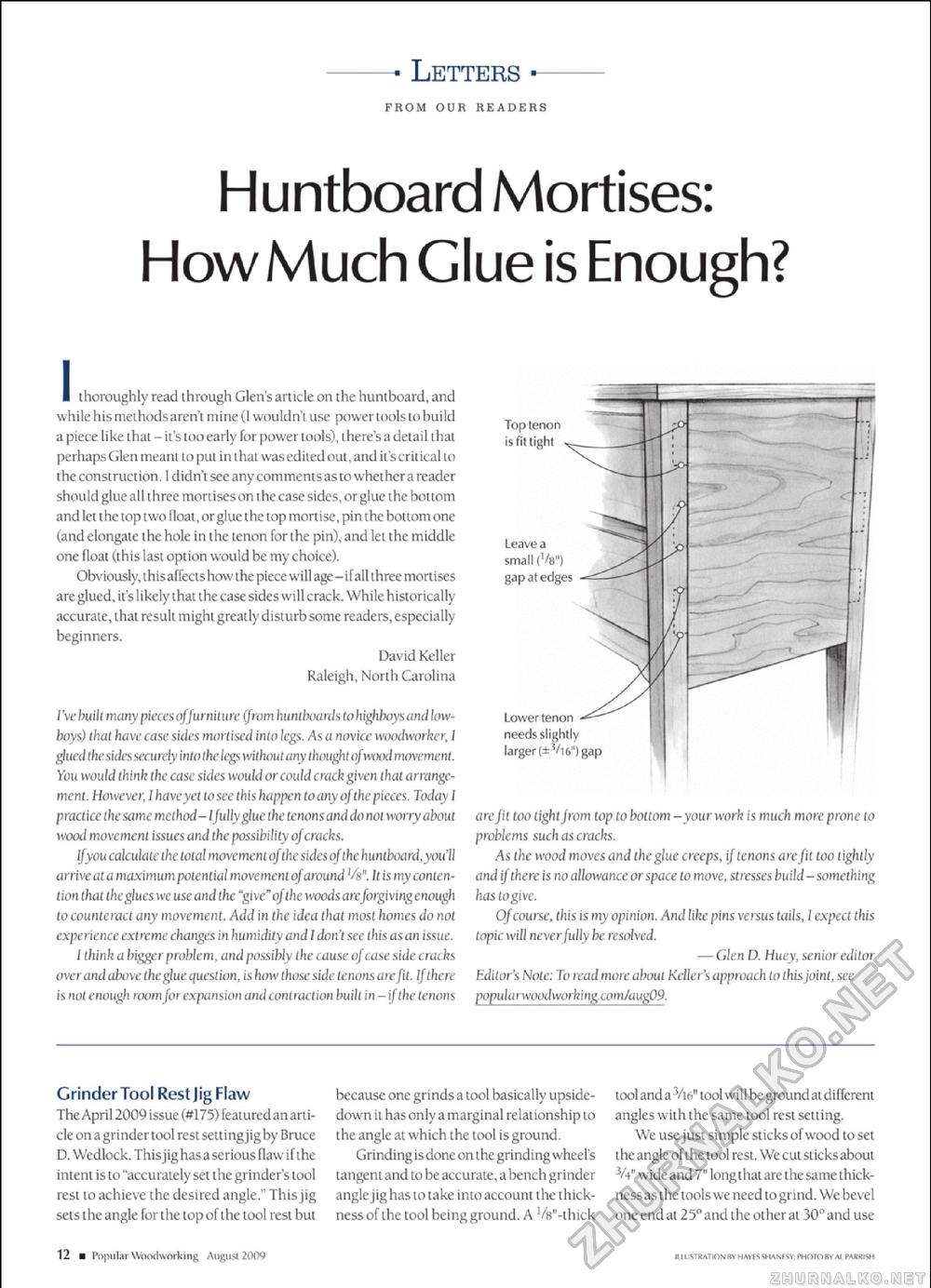

■ Letters ■ FROM OUR READERS Huntboard Mortises: How Much Glue is Enough? l thoroughly read through Glen's article on the huntboard, and while his methods aren't mine (I wouldn't use power tools to build a piece like that-it's too early for power tools), there'sa detail that perhaps Glen meant to put in that was edited out, and it's critical to the construction. 1 didn't see any comments as to whethera reader should glue all three mortises on the case sides, or glue the bottom and let the top two float, orglue the top mortise, pin the bottom one (and elongate I he hole in the tenon for the pin), and let the middle one float (this last option would be my choice). Obv iously, th isaffect s how the piece will age- i ral I th ree mori i ses are glued, it'slikely that the case sides will crack. Whilehistorically accurate, thai result might greatly disturb some readers, especially beginners. David Keller Raleigh, North Carolina I've built many pieces of furniture (from huntboa rds toh ighboys and low-bays) that have case sides mortised into legs. As a novice woodworker, I g tued the sides securely into (he tfgs wi(hou( any thoughtofwood movement. You would tftinfe the case sides would or could crack given that arrangement. However, I have yet to see (his happen to any of the pieces. Today 1 practice the same method-Ifully glue the tenonsand do not worry about wood movement issues and the possibility of cracks. ijyou calculate the total movement of the sides ojthe huntboard, you'll arrive at a maximum potential movement of around Vs". It is my contention that tliegluL's we use and the "give" of the woods arc /orgiving enough to counteract any movement. Add in the idea that most homes do not expe rience extreme changes in hum idity and 7 don't see this as an issue. i think a bigger problem, and possibly the cause of case side cracks over and above the glue question, is how those side tenons are fit. If there is not enough roomfor expansion and contractionbuilt in-if the tenons are fit too tightfrom top to bottom -your work is much more prone to problems suchascracks. As the wood moves and the glue creeps, if tenons arc fit too tightly and if there is no allowance or space to move, stresses build-something has to give. Of course, (his is my opinion. And fifee pins versus tuils, I expect this topic will never fully be resolved. —Glen D. Huey, senior editor Editor's Note: To read more about Keller's approach to this join(, see papula rwoo dworh i rig. com/aug09. Grinder Tool Restjig Flaw The April 2009 issue (#175) featured an article on a grinder tool re st settingjigby Bruce D. Wedlock. Thisjighasa serious flaw if the intent is to "accurately set the grinder'stool rest to achieve the desired angle." This jig sets the angle for the top of the tool rest but 12 ■ Popular Woodworking August 2009 because one grindsa tool basically upside-down it has only a marginal relationship to the angle at which the tool is ground. Grinding is done on the grinding wheel's tangentand to be accurate, a bench grinder angle jig has to lake imo account the thickness of the tool beingground. A l/s"-thick tool and a Me* tool will be ground atdifferent angles with the same tool rest setting. We use just simple sticks of wood to set Lhe angle of the tool rest. We cut sticks about Vt" wide and 7" long that are lhe same thickness as the tools we need to grind. We bevel one end at 23°and the other at 30°and use IIUKIRAT ONBY HAVES SHANISV PHOTOdV Al PyUtRISH Top tenon is fit tight Leave a small (Vs") gap at edges Lowertenon needs slightly larger (± Aft") gap |