Popular Woodworking 2009-10 № 178, страница 27

You can make this stool for your shop. It is also a handy piece of furniture to have around the house. The stool is 2"" higher than a typical chair. It places a child or a smaller adult at table height. Made in the 24" version, the stool is perfect for use at a counter or around an island. These stools are comfortable and you can sit on them a long time. Their design solves the problems that make most stools uncomfortable. The round top is big - an ample 14" wide. It will accommodate the widest backside. The top is dished to 3A". This depth allows you to sink into the top. A flat-topped stool is very uncomfortable. For a SketchUp model and a photo of a 24" stool with a baluster leg, go to: popularwoodworking.com/oct09 In spite of its delicate appearance, this stool is remarkably rugged. Some of mine have been in continual use for 30 years. While somewhat worn, the joints are still perfectly tight. They have stood up to hard treatment. Putting a Windsor chair together requires a chairmaker to move fast. Lots of parts have to go together at once. There is little time to gently move a stool into the desired position or out of the way. The job is usually done with the foot. The stool is kicked into place then shoved out of the way. They are frequently put on the bench. When they fall off they bounce across the floor. These stools are a good way to get some chairmaking experience without getting in over your head. Most woodworkers avoid chairs because of complicated geometry. Most chairs involve compound angles - parts lie in two planes. This stool uses only simple angles. The parts are all in one plane. Stools are seating furniture and part of the chairmaker's trade. So, in this article I will often refer to chairs and chairmaking when talking about the process of making this stool. One Afternoon of Lathe Work The stool is all lathe work. If you have good lathe skills you can make one in an afternoon. The top is face-plate turned. The four legs and stretchers are spindle turned - turned between centers. I use yellow poplar (tulip) for my stool tops. This wood is

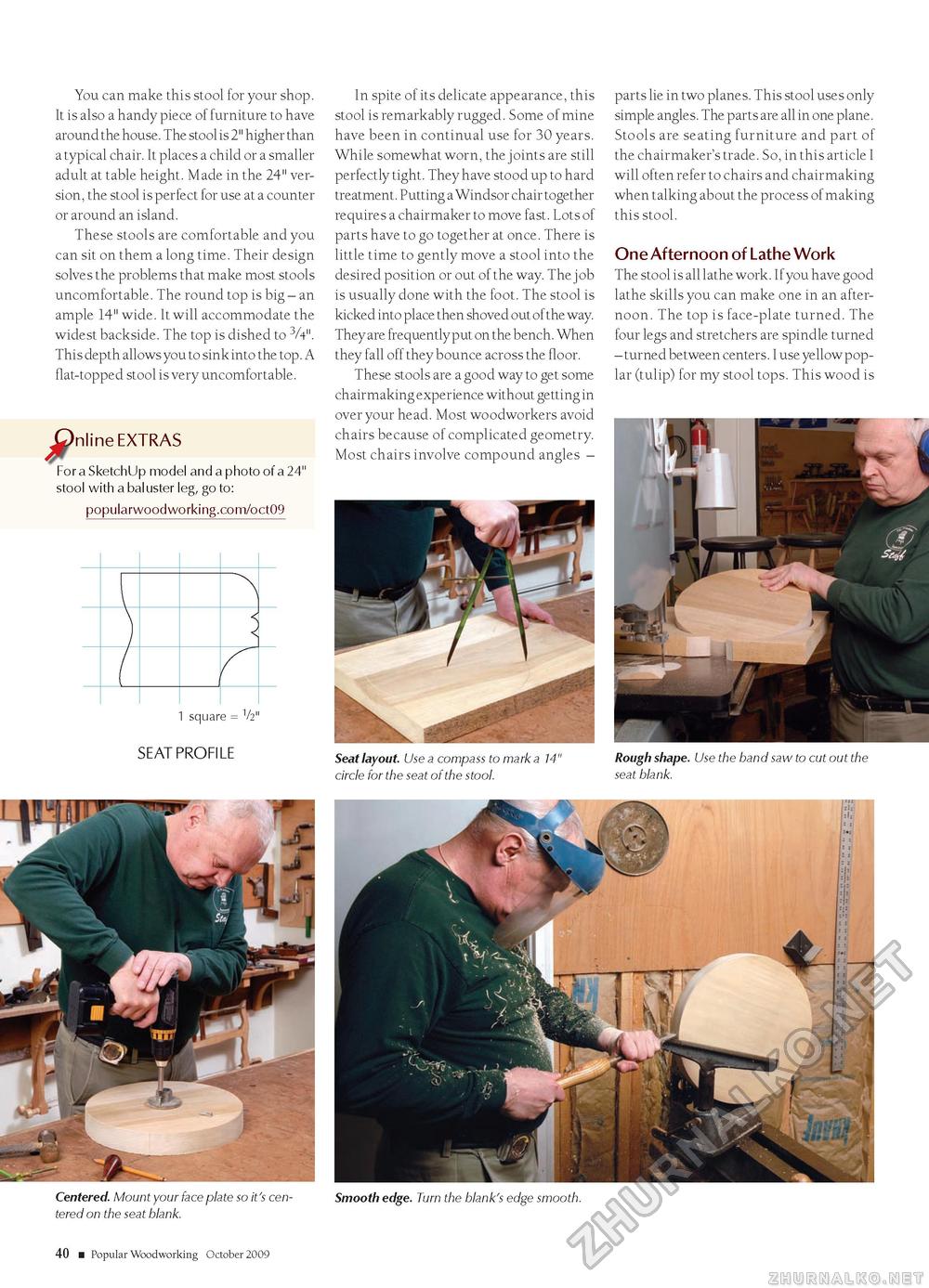

1 square = V2" 1 square = V2" seat profile Seat layout. Use a compass to mark a 14" circle for the seat of the stool. Rough shape. Use the band saw to cut out the seat blank. Centered. Mount your face plate so it's centered on the seat blank. Smooth edge. Turn the blank's edge smooth. 40 ■ Popular Woodworking October 2009 |