Popular Woodworking 2009-10 № 178, страница 28

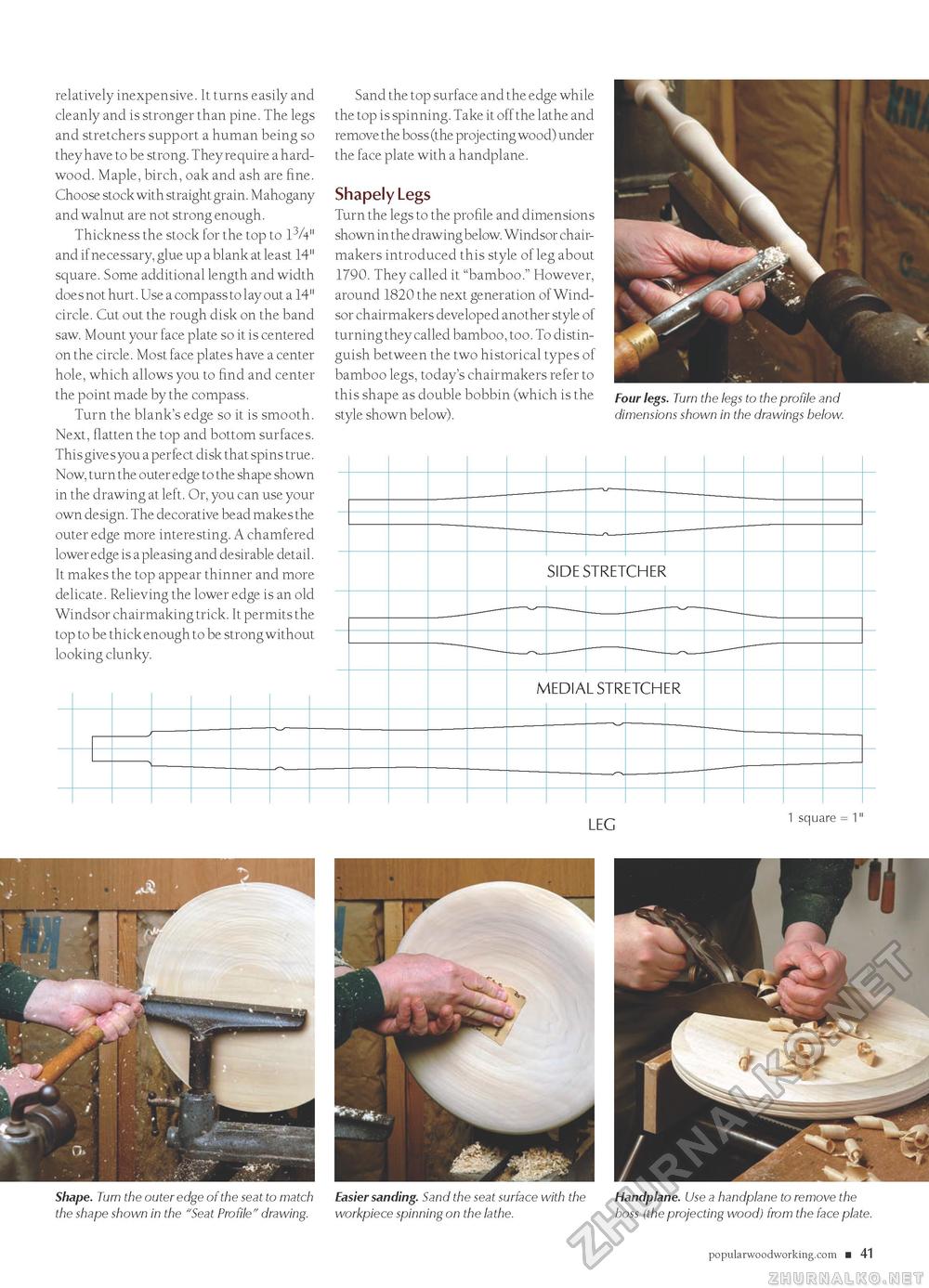

relatively inexpensive. It turns easily and cleanly and is stronger than pine. The legs and stretchers support a human being so they have to be strong. They require a hardwood. Maple, birch, oak and ash are fine. Choose stock with straight grain. Mahogany and walnut are not strong enough. Thickness the stock for the top to 13A" and if necessary, glue up a blank at least 14" square. Some additional length and width does not hurt. Use a comp ass to lay out a 14" circle. Cut out the rough disk on the band saw. Mount your face plate so it is centered on the circle. Most face plates have a center hole, which allows you to find and center the point made by the compass. Turn the blank's edge so it is smooth. Next, flatten the top and bottom surfaces. This gives you a perfect disk that spins true. Now, turn the outer edge to the shape shown in the drawing at left. Or, you can use your own design. The decorative bead makes the outer edge more interesting. A chamfered lower edge is a pleasing and desirable detail. It makes the top appear thinner and more delicate. Relieving the lower edge is an old Windsor chairmaking trick. It permits the top to be thick enough to be strong without looking clunky. Sand the top surface and the edge while the top is spinning. Take it off the lathe and remove the boss (the projecting wood) under the face plate with a handplane. Shapely Legs Turn the legs to the profile and dimensions shown in the drawing below. Windsor chair-makers introduced this style of leg about 1790. They called it "bamboo." However, around 1820 the next generation of Windsor chairmakers developed another style of turning they called bamboo, too. To distinguish between the two historical types of bamboo legs, today's chairmakers refer to this shape as double bobbin (which is the style shown below). Four legs. Turn the legs to the profile and dimensions shown in the drawings below. MEDIAL STRETCHER LEG 1 square = 1" Shape. Turn the outer edge of the seat to match Easier sanding. Sand the seat surface with the Handplane. Use a handplane to remove the the shape shown in the "Seat Profile" drawing. workpiece spinning on the lathe. boss (the projecting wood) from the face plate. popularwoodworking.com ■ 41 |