Popular Woodworking 2009-12 № 180, страница 7

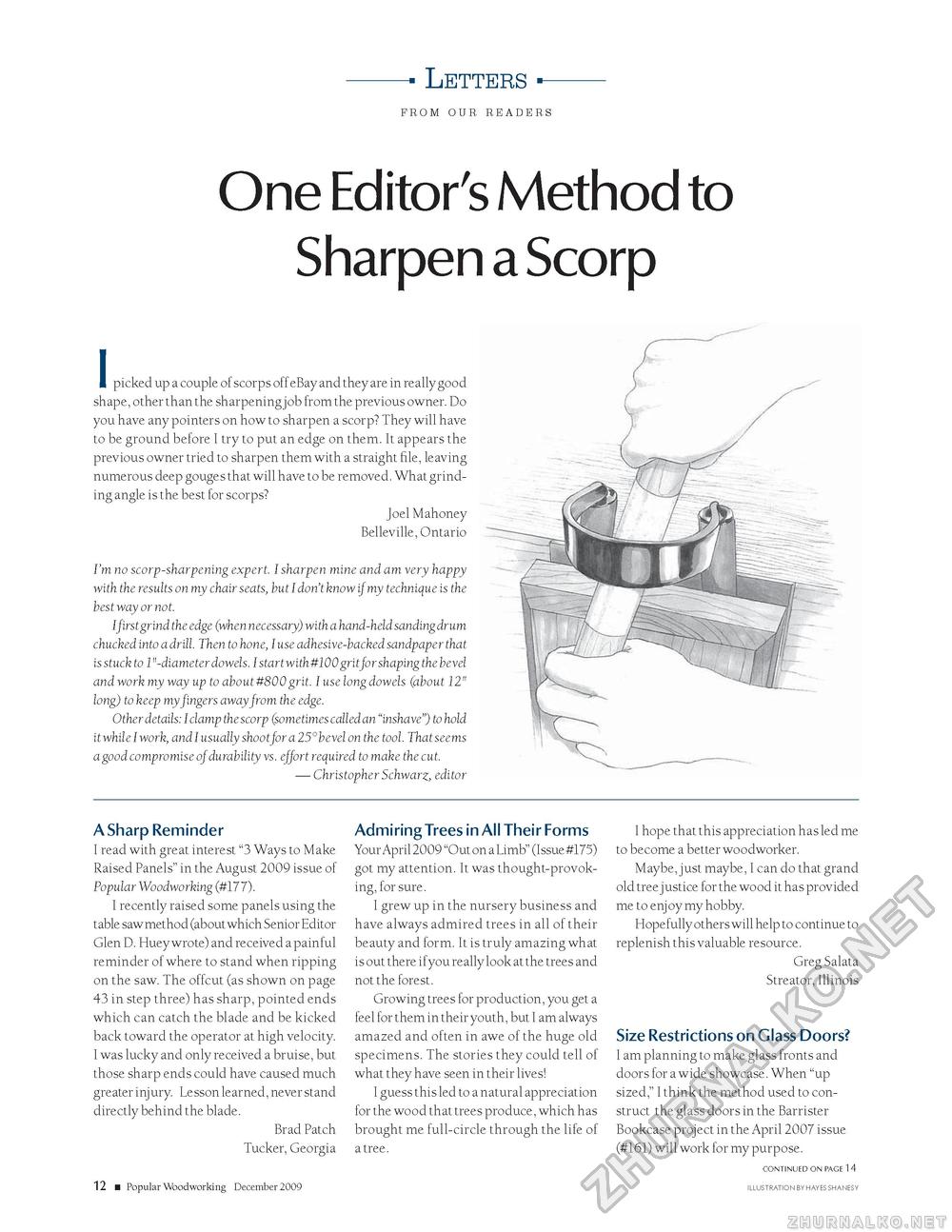

- Letters -FROM OUR READERS One Editor's Method to Sharpen a ScorpI picked up a couple of scorps off eBay and they are in really good shape, other than the sharpening job from the previous owner. Do you have any pointers on how to sharpen a scorp? They will have to be ground before I try to put an edge on them. It appears the previous owner tried to sharpen them with a straight file, leaving numerous deep gouges that will have to be removed. What grinding angle is the best for scorps? Joel Mahoney Belleville, Ontario I'm no scorp-sharpening expert. I sharpen mine and am very happy with the results on my chair seats, but I don't know if my technique is the best way or not. I first grind the edge (when necessary) with a hand-held sanding drum chucked into a drill. Then to hone, I use adhesive-backed sandpaper that is stuck to 1 "-diameter dowels. I start with #100 grit for shaping the bevel and work my way up to about#800grit. I use long dowels (about 12" long) to keep my fingers away from the edge. Other details: I clamp the scorp (sometimes called an "inshave") to hold it while I work, and I usually shoot for a 25° bevel on the tool. That seems a good compromise of durability vs. effort required to make the cut. — Christopher Schwarz, editor A Sharp ReminderI read with great interest "3 Ways to Make Raised Panels" in the August 2009 issue of Popular Woodworking (#177). I recently raised some panels using the table saw method (about which Senior Editor Glen D. Huey wrote) and received a painful reminder of where to stand when ripping on the saw. The offcut (as shown on page 43 in step three) has sharp, pointed ends which can catch the blade and be kicked back toward the operator at high velocity. I was lucky and only received a bruise, but those sharp ends could have caused much greater injury. Lesson learned, never stand directly behind the blade. Brad Patch Tucker, Georgia 12 ■ Popular Woodworking December 2009 Admiring Trees in All Their FormsYour April 2009 "Out on a Limb" (Issue #175) got my attention. It was thought-provoking, for sure. I grew up in the nursery business and have always admired trees in all of their beauty and form. It is truly amazing what is out there ifyou really look at the trees and not the forest. Growing trees for production, you get a feel for them in their youth, but I am always amazed and often in awe of the huge old specimens. The stories they could tell of what they have seen in their lives! I guess this led to a natural appreciation for the wood that trees produce, which has brought me full-circle through the life of a tree. I hope that this appreciation has led me to become a better woodworker. Maybe, just maybe, I can do that grand old tree justice for the wood it has provided me to enjoy my hobby. Hopefully others will help to continue to replenish this valuable resource. Greg Salata Streator, Illinois Size Restrictions on Glass Doors?I am planning to make glass fronts and doors for a wide showcase. When "up sized," I think the method used to construct the glass doors in the Barrister Bookcase project in the April 2007 issue (#161) will work for my purpose. CONTINUED ON PAGE 14 ILLUSTRATION BY HAYES SHANESY |