10 - Heavy Duty Lathe Stand, страница 22

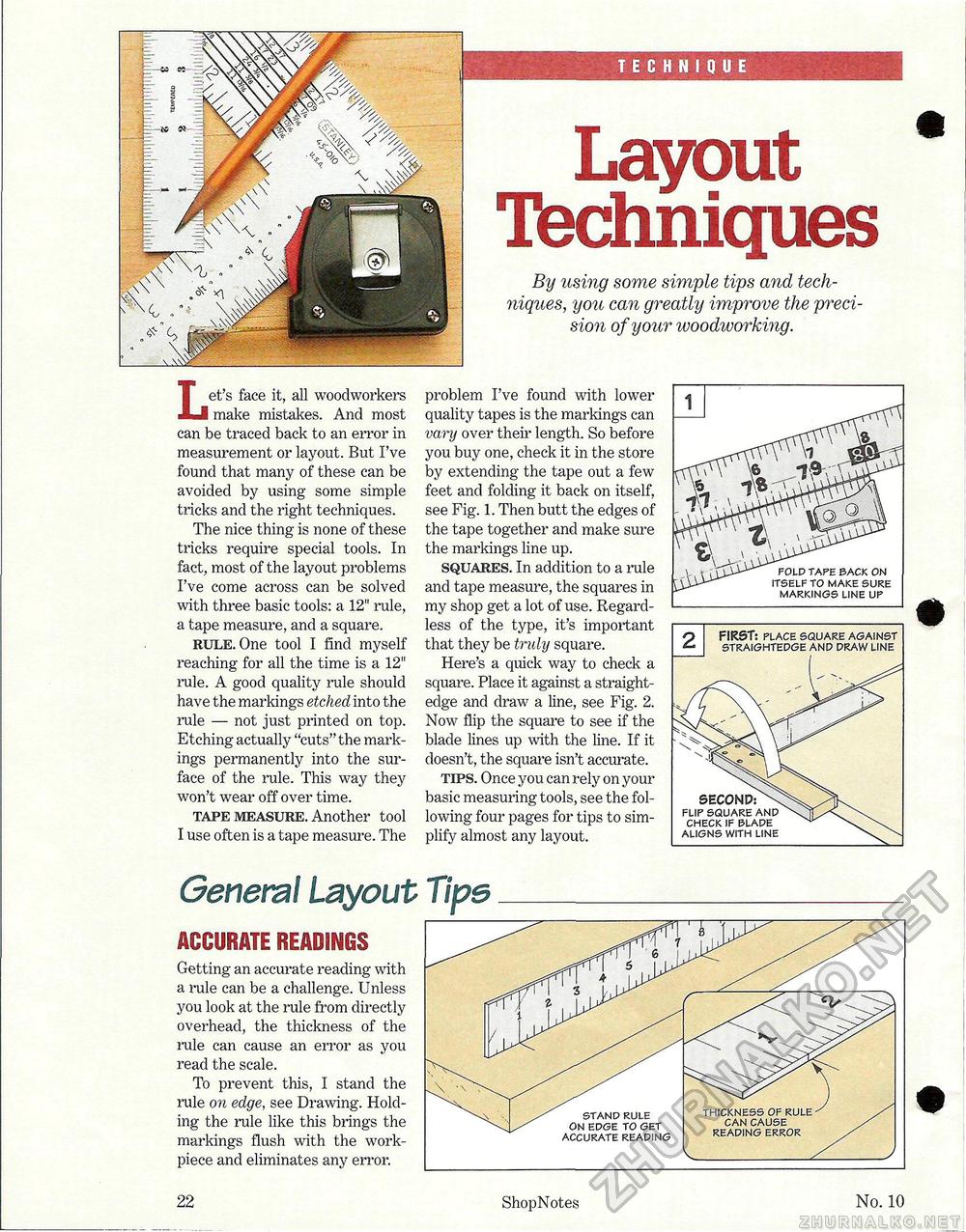

TECHNIQUE Let's face it, all woodworkers make mistakes. And most can be traced back to an error in measurement or layout. But I've found that many of these can be avoided by using some simple tricks and the right techniques. The nice thing is none of these tricks require special tools. In fact, most of the layout problems I've come across can be solved with three basic tools: a 12" rule, a tape measure, and a square. rule. One tool I find myself reaching for all the time is a 12" rule. A good quality rule should have the markings etched into the rule — not just printed on top. Etching actually "cuts" the markings permanently into the surface of the rule. This way they won't wear off over time. tape measure. Another tool I use often is a tape measure. The LayoutTechniquesBy using some simple tips and techniques, you can greatly improve the precision of your woodworking. problem I've found with lower quality tapes is the markings can vary over their length. So before you buy one, check it in the store by extending the tape out a few feet and folding it back on itself, see Fig. 1. Then butt the edges of the tape together and make sure the markings line up. squares. In addition to a rule and tape measure, the squares in my shop get a lot of use. Regardless of the type, it's important that they be truly square. Here's a quick way to check a square. Place it against a straightedge and draw a line, see Fig. 2. Now flip the square to see if the blade lines up with the line. If it doesn't, the square isn't accurate. tips. Once you can rely on your basic measuring tools, see the following four pages for tips to simplify almost any layout. FIRST: PLACE SQUARE AGAINST STRAIGHTEDGE AND DRAW LINE SECOND: FLIP SQUARE AND CHECK IF BLADE ALIGNS WITH LINE General Layout Tips ACCURATE READINGS THICKNESS OF RULE-CAN CAUSE READING ERROR Getting an accurate reading with a rule can be a challenge. Unless you look at the rule from directly overhead, the thickness of the rule can cause an error as you read the scale. To prevent this, I stand the rule on edge, see Drawing. Holding the rale like this brings the markings flush with the work-piece and eliminates any error. STAND RULE ON EDGE TO GET ACCURATE READING 22 ShopNotes No. 10 |