10 - Heavy Duty Lathe Stand, страница 4

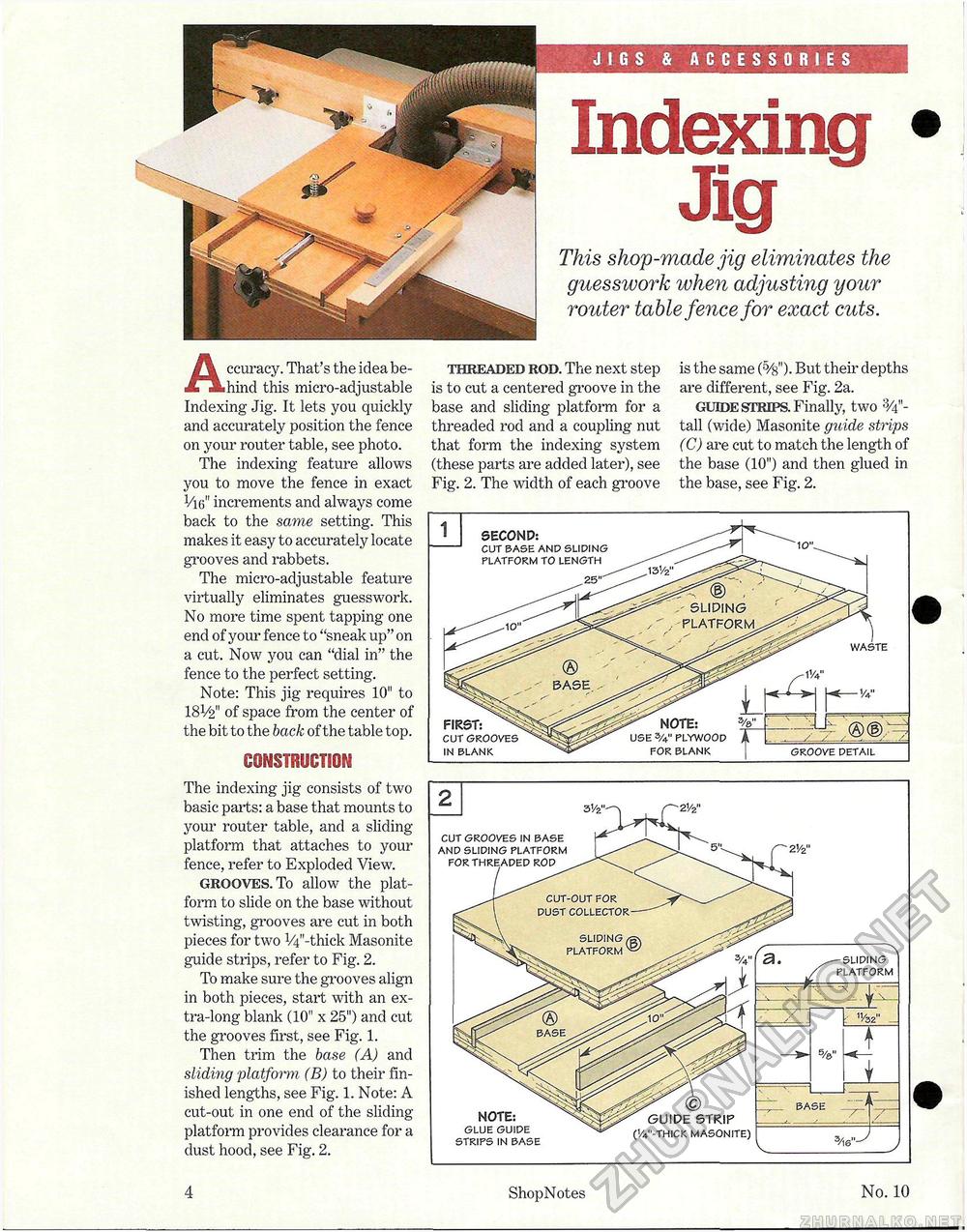

JIGS & ACCESSORIES Indexing Jig This shop-made jig eliminates the guesswork when adjusting your router table fence for exact cuts. Accuracy. That's the idea behind this micro-adjustable Indexing Jig. It lets you quickly and accurately position the fence on your router table, see photo. The indexing feature allows you to move the fence in exact Vie" increments and always come back to the same setting. This makes it easy to accurately locate grooves and rabbets. The micro-adjustable feature virtually eliminates guesswork. No more time spent tapping one end of your fence to "sneak up" on a cut. Now you can "dial in" the fence to the perfect setting. Note: This jig requires 10" to 18V£>" of space from the center of the bit to the back of the table top. CONSTRUCTION The indexing jig consists of two basic parts: a base that mounts to your router table, and a sliding platform that attaches to your fence, refer to Exploded View. grooves-To allow the platform to slide on the base without twisting, grooves are cut in both pieces for two V^'-thick Masonite guide strips, refer to Fig. 2. To make sure the grooves align in both pieces, start with an extra-long blank (10" x 25") and cut the grooves first, see Fig. 1. Then trim the base (A) and sliding platform (B) to their finished lengths, see Fig. 1. Note: A cut-out in one end of the sliding platform provides clearance for a dust hood, see Fig. 2. threaded rod. The next step is to cut a centered groove in the base and sliding platform for a threaded rod and a coupling nut that form the indexing system (these parts are added later), see Fig. 2. The width of each groove is the same (5/8M). But their depths are different, see Fig. 2a. guide strips. Finally, two tall (wide) Masonite guide strips (C) are cut to match the length of the base (10") and then glued in the base, see Fig. 2. 4 ShopNotes No. 10 |