15 - Sliding Table, страница 30

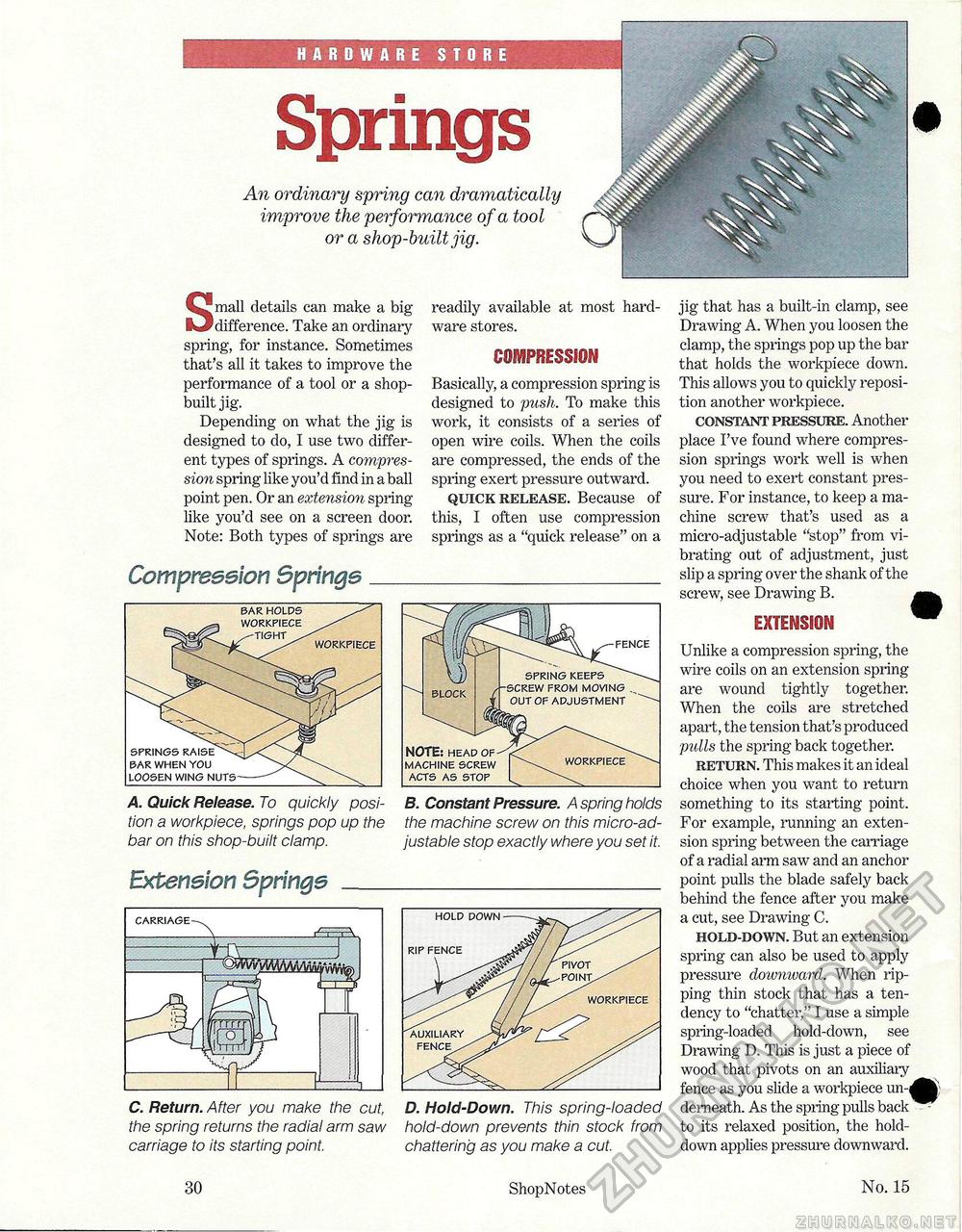

HARDWARE STORE SpringsAn ordinary spring can dramatically improve the performance of a tool or a shop-built jig. Small details can make a big difference. Take an ordinary spring, for instance. Sometimes that's all it takes to improve the performance of a tool or a shop-built jig. Depending on what the jig is designed to do, I use two different types of springs. A compression spring like you'd find in a ball point pen. Or an extension spring like you'd see on a screen door. Note: Both types of springs are Compreeelon Springe_ readily available at most hardware stores. compression Basically, a compression spring is designed to push. To make this work, it consists of a series of open wire coils. When the coils are compressed, the ends of the spring exert pressure outward. quick release. Because of this, I often use compression springs as a "quick release" on a

NOTE: HEAD OF MACHINE SCREW ACTS AS STOP A. Quick Release. To quickly position a workpiece, springs pop up the bar on this shop-built clamp. Extension Springe _ B. Constant Pressure. A spring holds the machine screw on this micro-adjustable stop exactly where you set it. C. Return. After you make the cut, the spring returns the radial arm saw carriage to its starting point. D. Hold-Down. This spring-loaded hold-down prevents thin stock from chattering as you make a cut. jig that has a built-in clamp, see Drawing A. When you loosen the clamp, the springs pop up the bar-that holds the workpiece down. This allows you to quickly reposition another workpiece. constant pressure. Another place I've found where compression springs work well is when you need to exert constant pressure. For instance, to keep a machine screw that's used as a micro-adjustable "stop" from vibrating out of adjustment, just slip a spring over the shank of the screw, see Drawing B. extension ^ Unlike a compression spring, the wire coils on an extension spring-are wound tightly together. When the coils are stretched apart, the tension that's produced pulls the spring back together. return. This makes it an ideal choice when you want to return something to its starting point. For example, running an extension spring between the carriage of a radial arm saw and an anchor point pulls the blade safely back behind the fence after you make a cut, see Drawing C. hold-down. But an extension spring can also be used to apply pressure downward. When ripping thin stock that has a tendency to "chatter," I use a simple spring-loaded hold-down, see Drawing D. This is just a piece of wood that pivots on an auxiliary fence as you slide a workpiece un-d^^; demeath. As the spring pulls back -to its relaxed position, the hold-down applies pressure downward. BLOCK NOTE: HEAD OF MACHINE SCREW ACTS AS STOP HOLD DOWN RIP FENCE FENCE 30 ShopNotes No. 15 |