25 - Special Table Saw Issue, страница 25

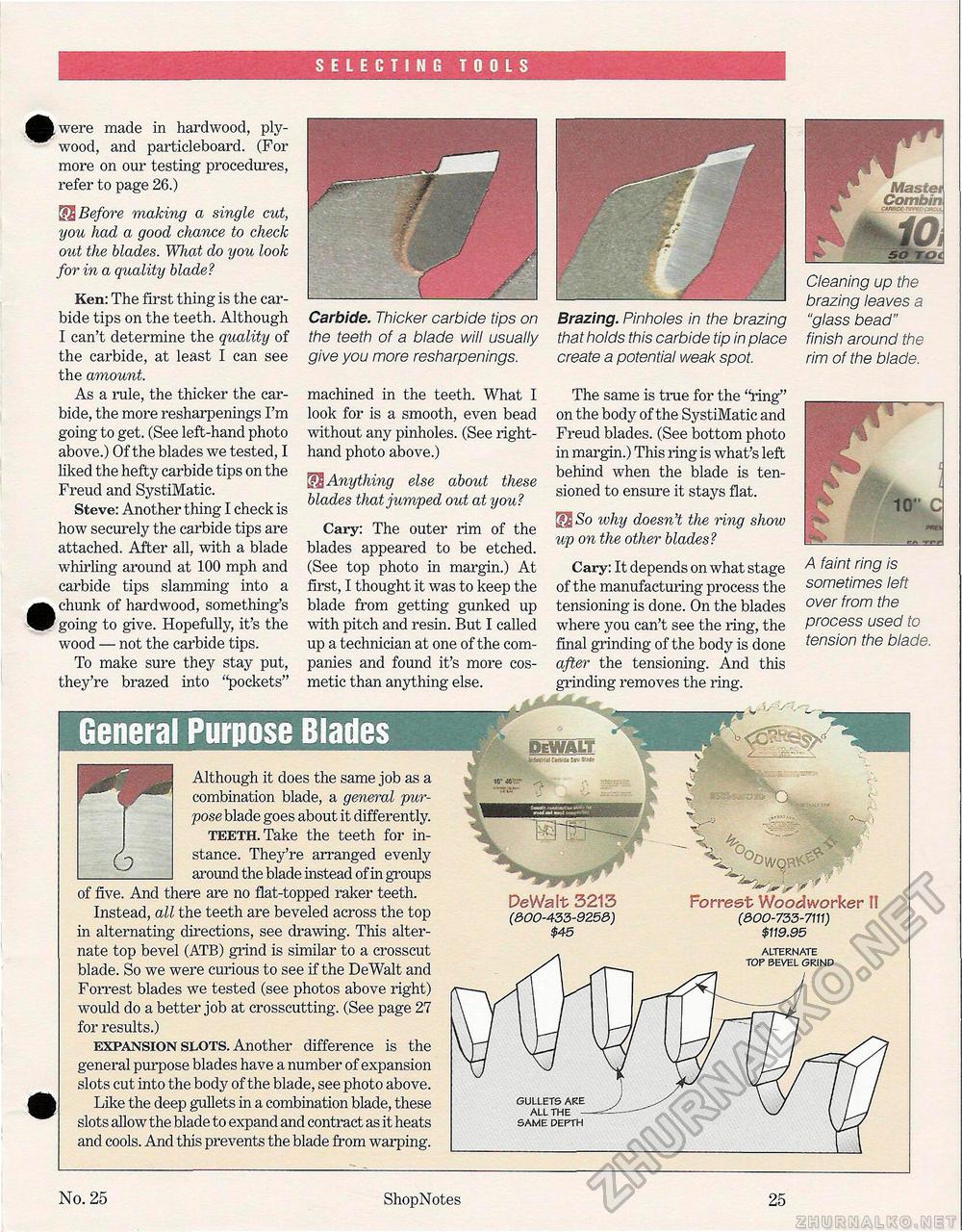

SELECTING TOOLS ^^ were made in hardwood, plywood, and particleboard. (For more on our testing procedures, refer to page 26.) E8 Before making a single cut, you had a good chance to check out the blades. What do you look for in a quality blade? Carbide. Thicker carbide tips on the teeth of a blade will usually give you more resharpenings. Brazing. Pinholes in the brazing that holds this carbide tip in place create a potential weak spot. Cleaning up the brazing leaves a "glass bead" finish around the rim of the blade. No. 25 ShopNotes 25 PeWALT General Purpose Blades Ken: The first thing is the carbide tips on the teeth. Although I can't determine the quality of the carbide, at least I can see the amount As a rule, the thicker the carbide, the more resharpenings I'm going to get. (See left-hand photo above.) Of the blades we tested, I liked the hefty carbide tips on the Freud and SystiMatic. Steve: Another thing I check is how securely the carbide tips are attached. After all, with a blade whirling around at 100 mph and carbide tips slamming into a chunk of hardwood, something's going to give. Hopefully, it's the wood — not the carbide tips. To make sure they stay put, they're brazed into "pockets" machined in the teeth. What I look for is a smooth, even bead without any pinholes. (See right-hand photo above.) 0.Anything else about these blades that jumped out at you? Cary: The outer rim of the blades appeared to be etched. (See top photo in margin.) At first, I thought it was to keep the blade from getting gunked up with pitch and resin. But I called up a technician at one of the companies and found it's more cosmetic than anything else. The same is true for the "ring" on the body of the SystiMatic and Freud blades. (See bottom photo in margin.) This ring is what's left behind when the blade is ten-sioned to ensure it stays flat. So ivhy doesn't the ring shoiv up on the other blades? Cary: It depends on what stage of the manufacturing process the tensioning is done. On the blades where you can't see the ring, the final grinding of the body is done after the tensioning. And this grinding removes the ring. A faint ring is sometimes left over from the process used to tension the blade. GULLETS ARE ALL THE SAME DEPTH Although it does the same job as a combination blade, a general purpose blade goes about it differently. teeth. Take the teeth for instance. They're arranged evenly around the blade instead of in groups of five. And there are no flat-topped raker teeth. Instead, all the teeth are beveled across the top in alternating directions, see drawing. This alternate top bevel (ATB) grind is similar to a crosscut blade. So we were curious to see if the DeWalt and Forrest blades we tested (see photos above right) would do a better job at crosscutting. (See page 27 for results.) expansion slots. Another difference is the general purpose blades have a number of expansion slots cut into the body of the blade, see photo above. Like the deep gullets in a combination blade, these slots allow the blade to expand and contract as it heats and cools. And this prevents the blade from warping. DeWalt 3213 (300-433-9253) $45 ^ (r Forrest Woodworker 11 (300-733-7111) $119.95 ALTERNATE TOP BEVEL GRIND |