25 - Special Table Saw Issue, страница 23

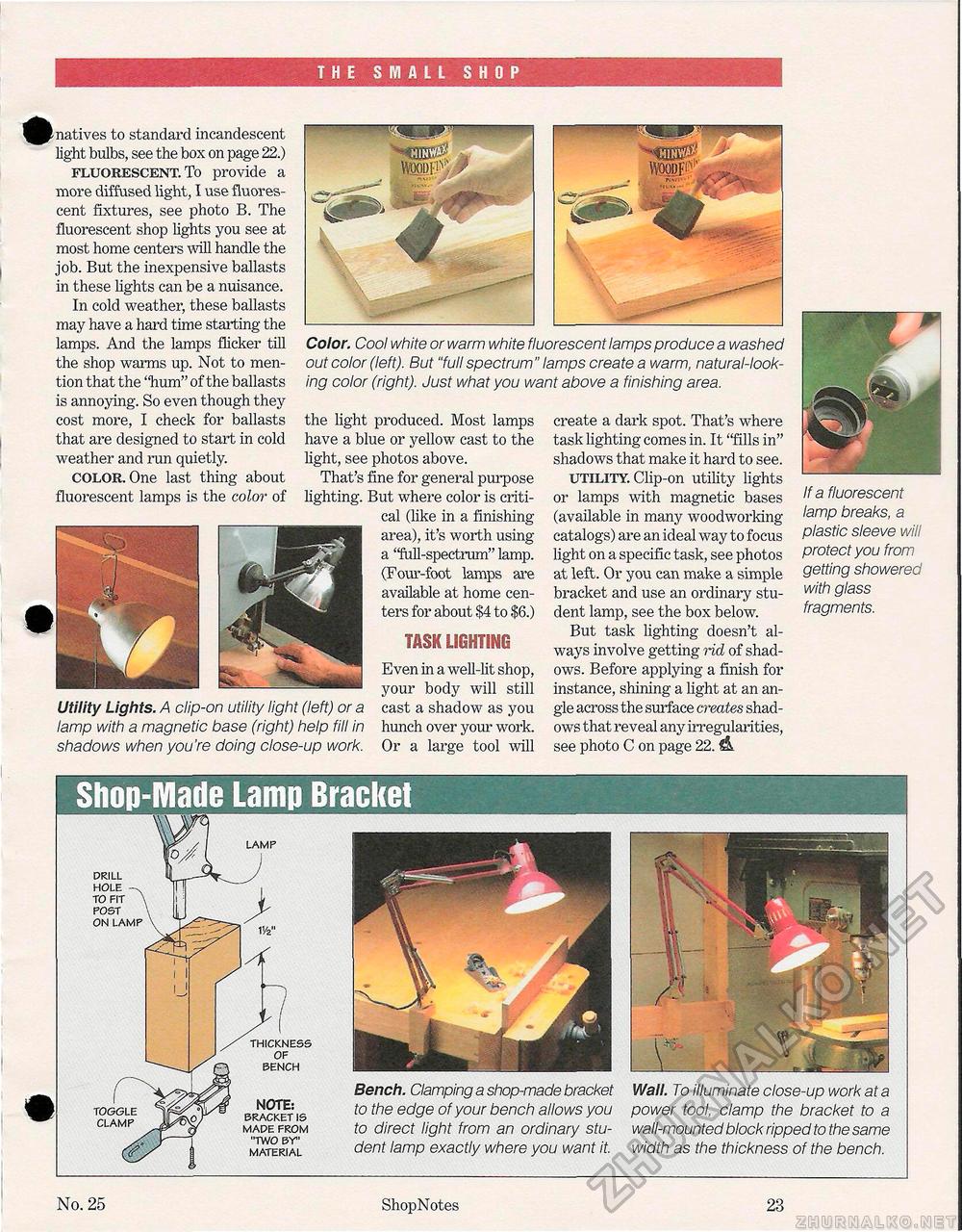

THE SMALL SHOP If a fluorescent lamp breaks, a plastic sleeve will protect you from getting showered with glass fragments. t natives to standard incandescent light bulbs, see the box on page 22.) fluorescent. To provide a more diffused light, I use fluorescent fixtures, see photo B. The fluorescent shop lights you see at most home centers will handle the job. But the inexpensive ballasts in these lights can be a nuisance. In cold weather, these ballasts may have a hard time starting the lamps. And the lamps flicker till the shop warms up. Not to mention that the "hum" of the ballasts is annoying. So even though they cost more, I check for ballasts that are designed to start in cold weather and run quietly. color. One last thing about fluorescent lamps is the color of Color. Cool white or warm white fluorescent lamps produce a washed out color (left). But "full spectrum" lamps create a warm, natural-looking color (right). Just what you want above a finishing area. Utility Lights. A clip-on utility light (left) or a lamp with a magnetic base (right) help fill in shadows when you're doing close-up work. the light produced. Most lamps have a blue or yellow cast to the light, see photos above. That's fine for general purpose lighting. But where color is critical (like in a finishing-area), it's worth using a 'full-spectrum" lamp. (Four-foot lamps are available at home centers for about $4 to $6.) TASK LIGHTING Even in a well-lit shop, your body will still cast a shadow as you hunch over your work. Or a large tool will create a dark spot. That's where task lighting comes in. It "fills in" shadows that make it hard to see. utility. Clip-on utility lights or lamps with magnetic bases (available in many woodworking catalogs) are an ideal way to focus light on a specific task, see photos at left. Or you can make a simple bracket and use an ordinary student lamp, see the box below. But task lighting doesn't always involve getting rid of shadows. Before applying a finish for instance, shining a light at an angle across the surface creates shadows that reveal any irregularities, see photo C on page 22. ik Shop-Made Lamp BracketBench. Clamping a shop-made bracket to the edge of your bench allows you to direct light from an ordinary student lamp exactly where you want it. lamp DRILL HOLE TO FIT POST ON LAMP TOGGLE CLAMP Wall. To illuminate close-up work at a power tool, clamp the bracket to a wall-mounted block ripped to the same width as the thickness of the bench. of bench NOTE: BRACKET IS MADE FROM "TWO BY' MATERIAL No. 25 ShopNotes 23 |